UM353-1B Function Blocks

April 2012

3-25

3.2.17 AWE_ - Analog Write Ethernet

AWE_ function blocks use Modbus command 16

“Preset Multiple Registers” to enable the controller to

write analog data to other Modbus devices over the

Ethernet network.

Up to 32 AWE_ blocks are available. Blocks are

assigned in sequence (e.g. AWE01, AWE02, …),

controller wide, with each use.

Data can be written as a real floating-point number or

as a 16-bit integer as configured by the DATA TYP

parameter. A Floating point number can be selected to

have one of four byte orders (BYTE ORD) with 1

being the most common (see Table 3-4 under AIE

block description). An integer is converted from the

block input S, which is a floating point number, by the

MIN INT and MAX INT parameters using the range

scaling information obtained from the source function

block in the controller with the range pointer input R.

Both Unsigned Integer (Uint) and Signed Integer (Sint)

options are available. See the table listing parameters

and default values below right.

The IP ADRES parameter is used to configure the IP address of

the destination Modbus device. The MB ADRES parameter

allows a Modbus address to be configured. When connecting to

other Siemens 353 controllers the Modbus address is set to 1. In

some cases, other devices may use a different address or when

going through a Modbus/TCP gateway a Modbus network may

have multiple devices, each having a unique Modbus address.

There are three write update options that can be configured by the UD TYPE parameter.

1. oncE will write once to the MB REG (Modbus Register). The controller will write when the input value

changes by more than the value set with the TRIG DB parameter. This parameter is set based on a percentage

of the range determined by the range pointer input R.

2. P2P will update at the controller peer to peer rate set in the ETHERNET block.

3. Ct will update at the cycle time of the controller.

The Ct option is normally only used when writing to I/O outputs in a PID control loop. Input T can be used to

trigger a write. This would be used in cases where the oncE option has been selected, Input S does not change so as

to trigger a write based on the trigger dead band, and there may be a concern that the receiving device has lost the

value.

Output QS indicates the quality of the write operation and will go high (1) when the write is not completed

successfully. This is normally associated with failure of the destination device to receive data due to a

communication failure or a misconfiguration of the device.

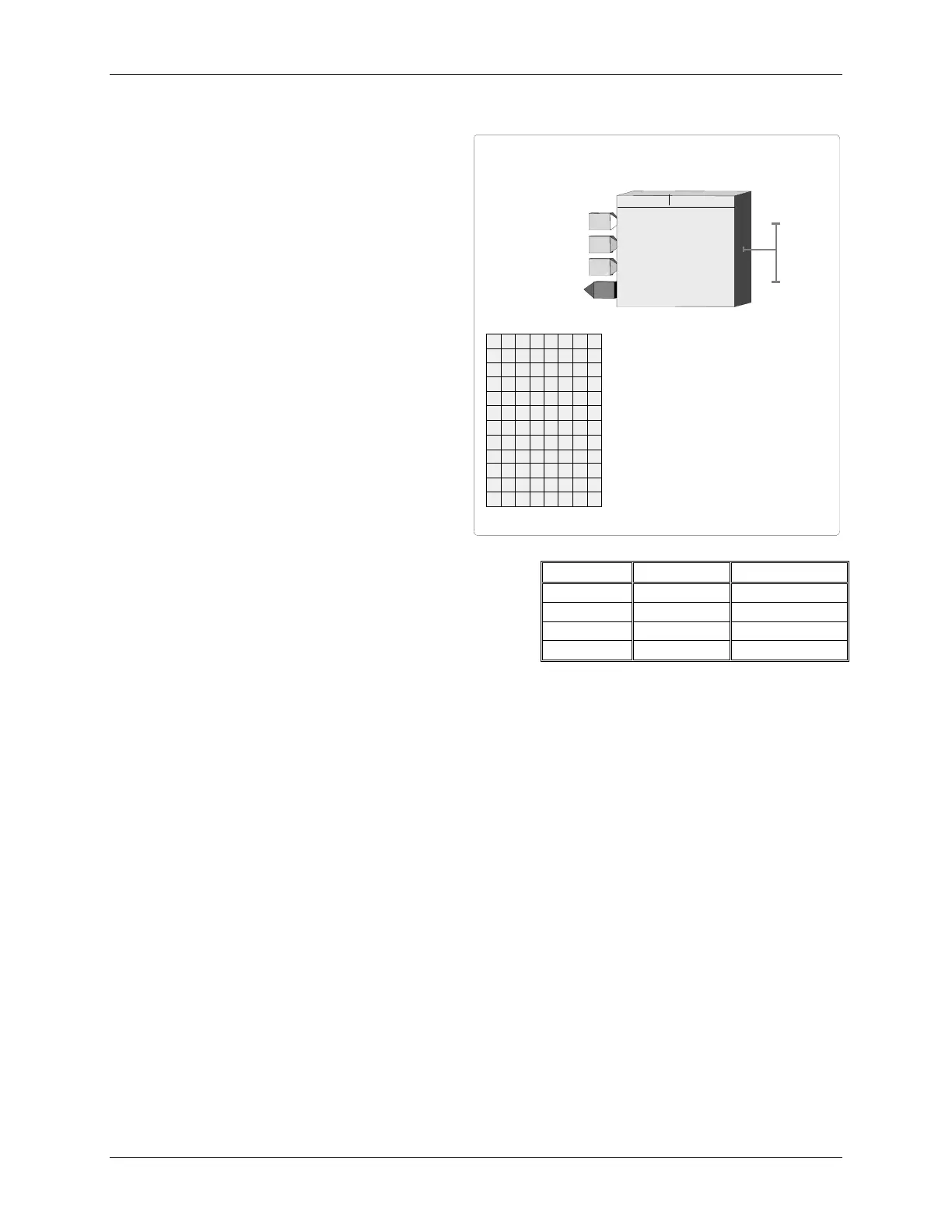

Selection Parameter Default Value

Uint

MIN INT 0

Uint

MAX INT 65535

Sint

MIN INT -32768

Sint

MAX INT +32767

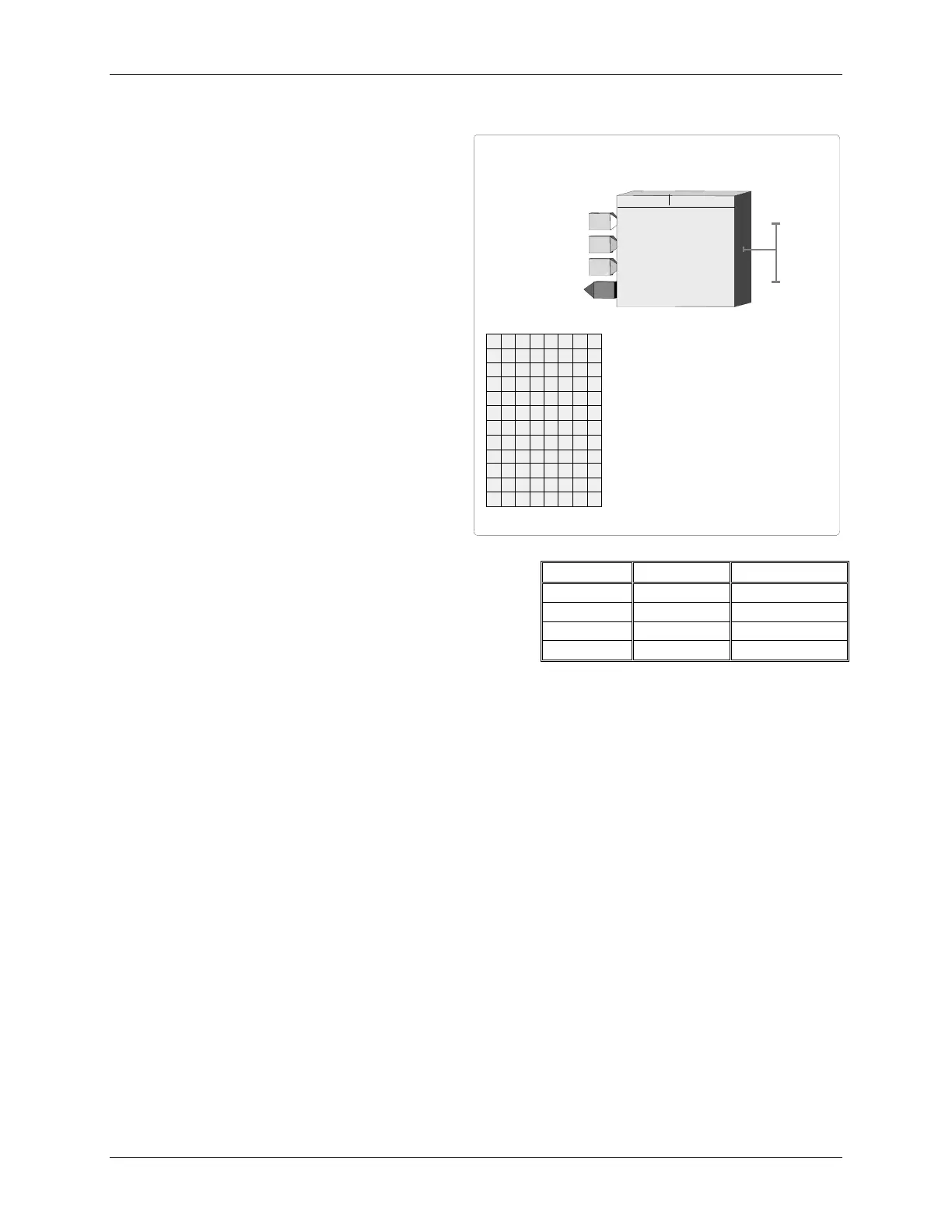

ANALOG WRITE - ETHERNET

ANALOG WRITE

AWE_

Input T

T

INPUT

S

(H)

........... loop tag.block tag.output

(null)

GPTR

R

an

G

e

P

oin

T

e

R

(H) .......... loop tag.block tag

(null)

R

ange

R

ETHERNET

Ethernet Network

R

NIPUTS

MB ADRES

MB AD

d

RES

s

(H)

.............................. 0 - 255

(0)

R

EGBM

M

od

B

us

REG

ister

(H)

.................... 1 - 65535

(1)

D

AT A TYP

Modbus

DATA

TYP

e

(H)

..........

FP

/

Uint

/

Sint

(FP)

B

YEOR

BYTE

ORD

er

(S)

................................ 1/2/3/4 (1)

MIN

imum

INT

eger

(S)

................. (see table)

(*)

MAX

imum

INT

eger

(S)

................ (see table)

(*)

INTMIN

MA X I N T

U

D

D

TYP

U

p

D

ate

TYPE

(H) .................... oncE/P2P/Ct

(oncE)

T

R

IG

TRIG

ger

D

ead

B

and

(S)

............ 0.1 - 10.0 %

(0.2)

QS

Q

uality

S

tatus

DB

IP ADRES

IP AD

d

RES

s

(H)

............ nnn.nnn.nnn.nnn

(192.168.0.0)

T

Input

S

S

E

NIPUTT

INPUT

T

(H)

........... loop tag.block tag.output

(null)

Loading...

Loading...