UM353-1B Function Blocks

April 2012

3-47

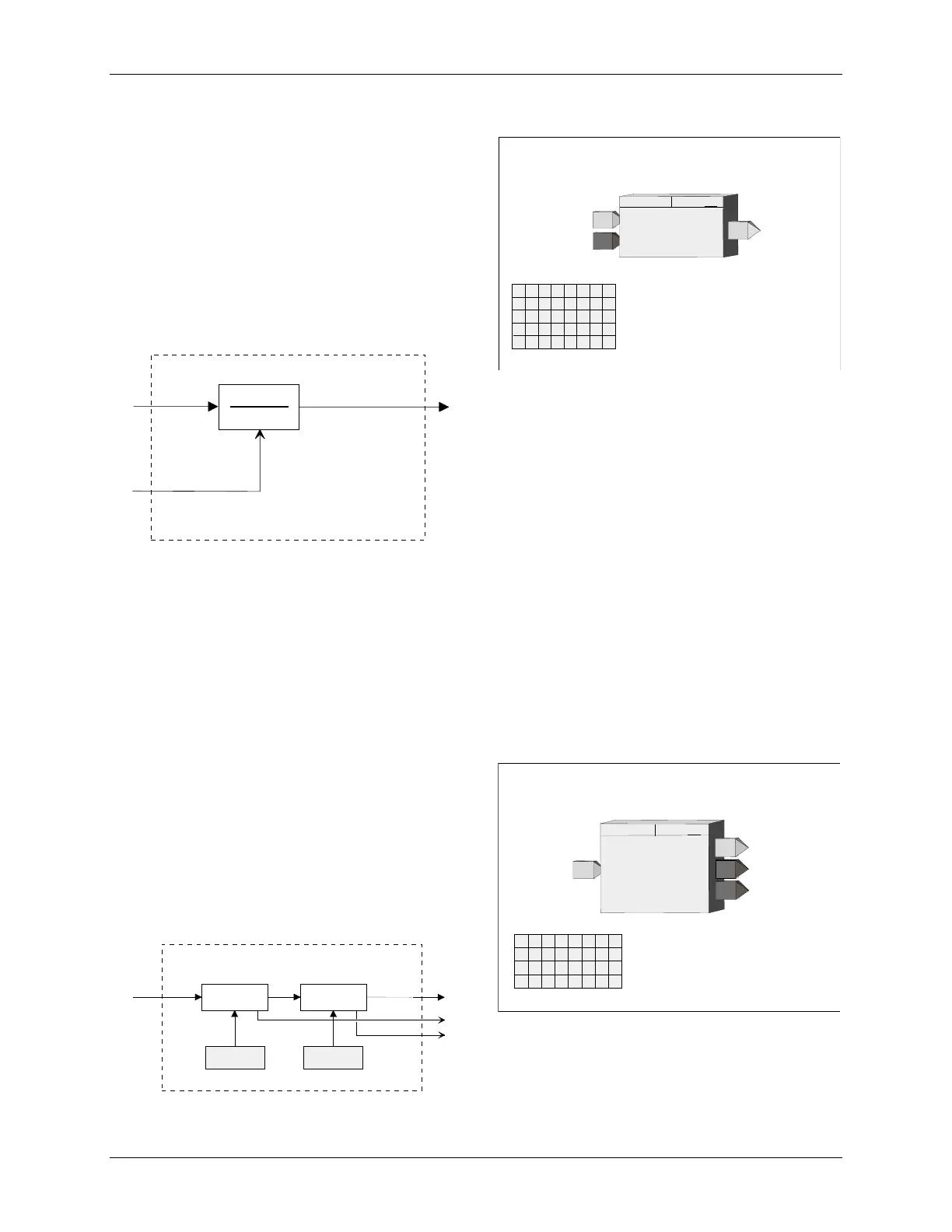

3.2.45 LL_ - Lead/Lag

LL_ function blocks provide both lead and lag functions.

The block can function as lag only by setting the TLEAD

time to 0.0. The lag function is always active and has a

minimum setting of 0.01 minutes.

Input E asserted high (1) will enable the Lead/Lag

function. When asserted low (0), the Lead/Lag function

will be bypassed and the output will be set equal to the

input. If input E is not configured, the block will be

enabled.

BLOCK DIAGRAM

O1

E

A

t

Lead

+ 1

t

Lag

+ 1

E

nable

A

nalog Input

O

utput

1

.

POWER UP - During a warm or cold start, the dynamic elements and the output will be initialized to the value of

the current input on the first scan.

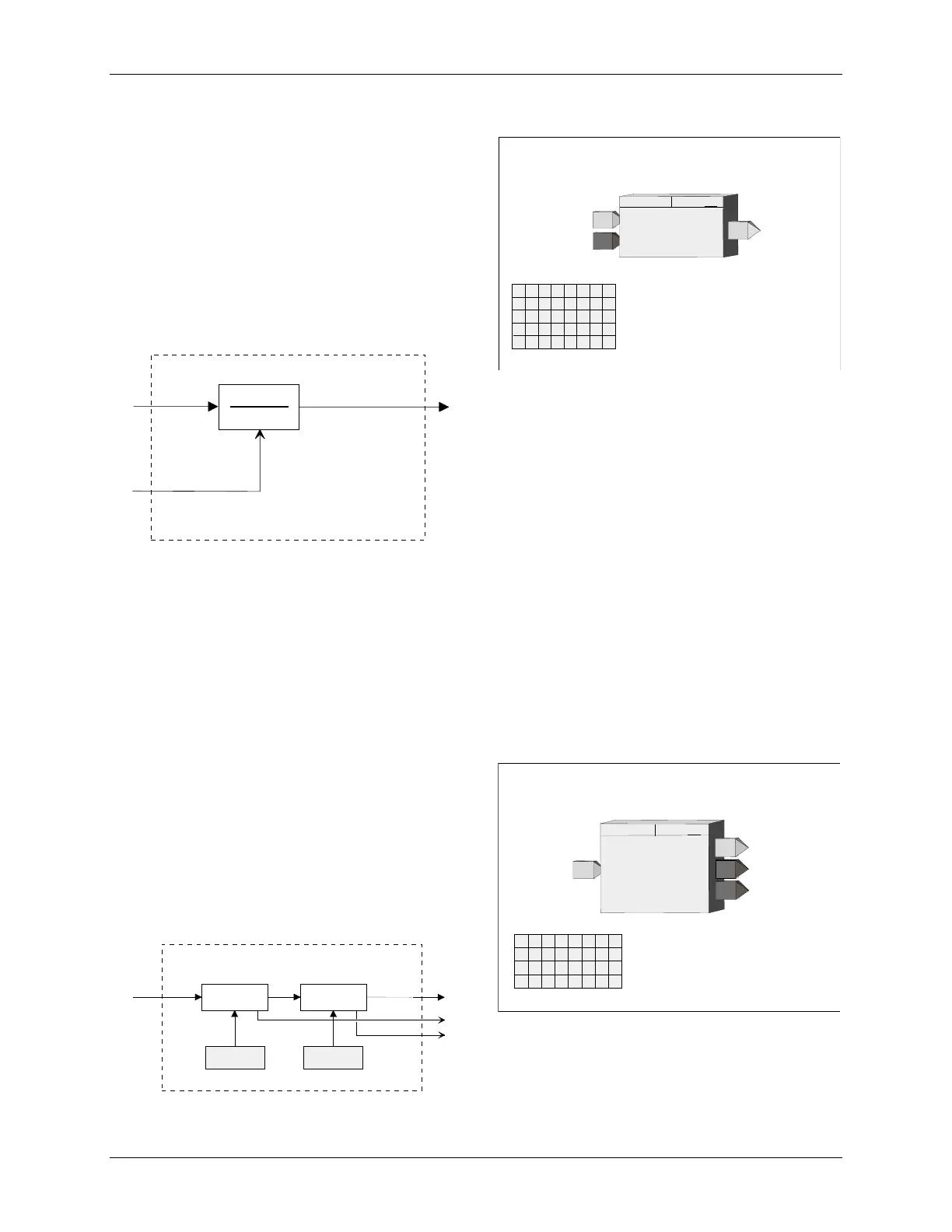

3.2.46 LMT_ - Limit

LMT_ function blocks are used to limit a real signal.

Input A will normally pass through the function block to

the output O1. If the input exceeds one of the limits, the

block will output the limit value.

If the HI LIMIT is set lower than the LO LIMIT, the block

will output the high limit value. The output statuses will

be high (1) when the block is in a limit condition.

BL

K DIA

RAM

HI SELECTOR

LO SELECTOR

HI LIMIT

A

O1

LO LIMIT

HS

LS

O

utput

1

H

igh limit

S

tatus

L

ow limit

S

tatus

.

.

A

nalog Input

LEAD/LAG

G

T

T

L

E

T

ime -

LAG

(min)

(S)

....... 0.01 - 10000.0 (0.10)

T

ime -

LEAD

(min)

(S)

..... 0.00 - 10000.0 (0.00)

O1

O

utput

1

LEAD/LAG

LL_

ESN =

000

A

L

A

E

E

nable

I

I

N

N

P

P

U

U

T

T

A

E

INPUT E

(H)

...........

loop tag.block tag.output (null

)

ESN

E

xec.

S

eq.

N

o.

(H)

................. 001 to 250

A

D

INPUT A

(H)

..........

loop tag.block tag.output (null)

Input

A

LIMIT

TI

H

I

O

L

I

N

U

A

HI

gh

LIMIT

(S)

........................... Real (100.00)

LO

w

LIMIT

(S)

........................... Real (0.00)

INPUT A

(H)

.....

loop tag.block tag.output (null)

HS

H

igh

S

tatus

LIMIT

LMT_

ESN =

000

I

M

L

T

P

A

L

I

M

I

T

ESN

E

xec.

S

eq.

N

o.

(H)

............ 001 to 250

O1

O

utput

1

L

ow

S

tatus

LS

Loading...

Loading...