UM353-1B Function Blocks

April 2012

3-33

1. oncE will write once to the START CL (Modbus Starting Coil. The controller will write when any block input

value changes state.

2. P2P will update at the controller peer to peer rate set in the ETHERNET block.

3. Ct will update at the cycle time of the controller.

The Ct option is normally only used when writing time critical changes. Input T can be used to trigger a write. This

would be used in cases where the oncE option has been selected, input values do not change, and there may be a

concern that the receiving device has lost the values.

Output QS indicates the quality of the write operation and will go high (1) when the write is not completed

successfully. This is normally associated with failure of the destination device to receive data due to a

communication failure or a misconfiguration of the device.

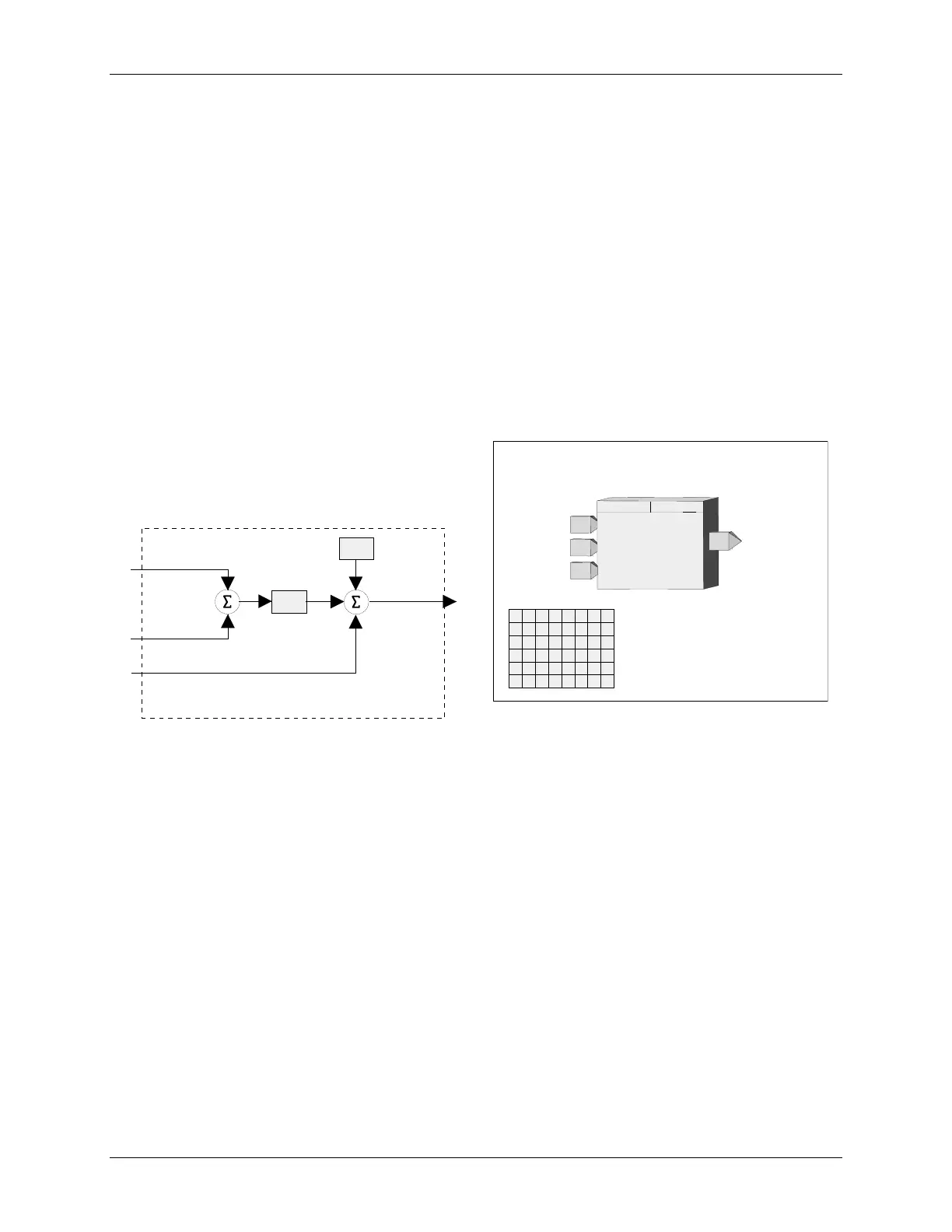

3.2.26 DAM_ - Deviation Amplifier

DAM_ function blocks compute the difference between

inputs A and B, amplify the difference signal, and sum the

resultant with an internal BIAS and an external signal at

input C. Unused inputs are set to 0.0.

BLOCK DIAGRAM

A

O

utput

1

-

GAIN

+

O1

BIAS

Input

A

Input

B

Input

C

B

C

+

+

+

O1 = GAIN x (A - B) + BIAS + C

.

.

Input

A

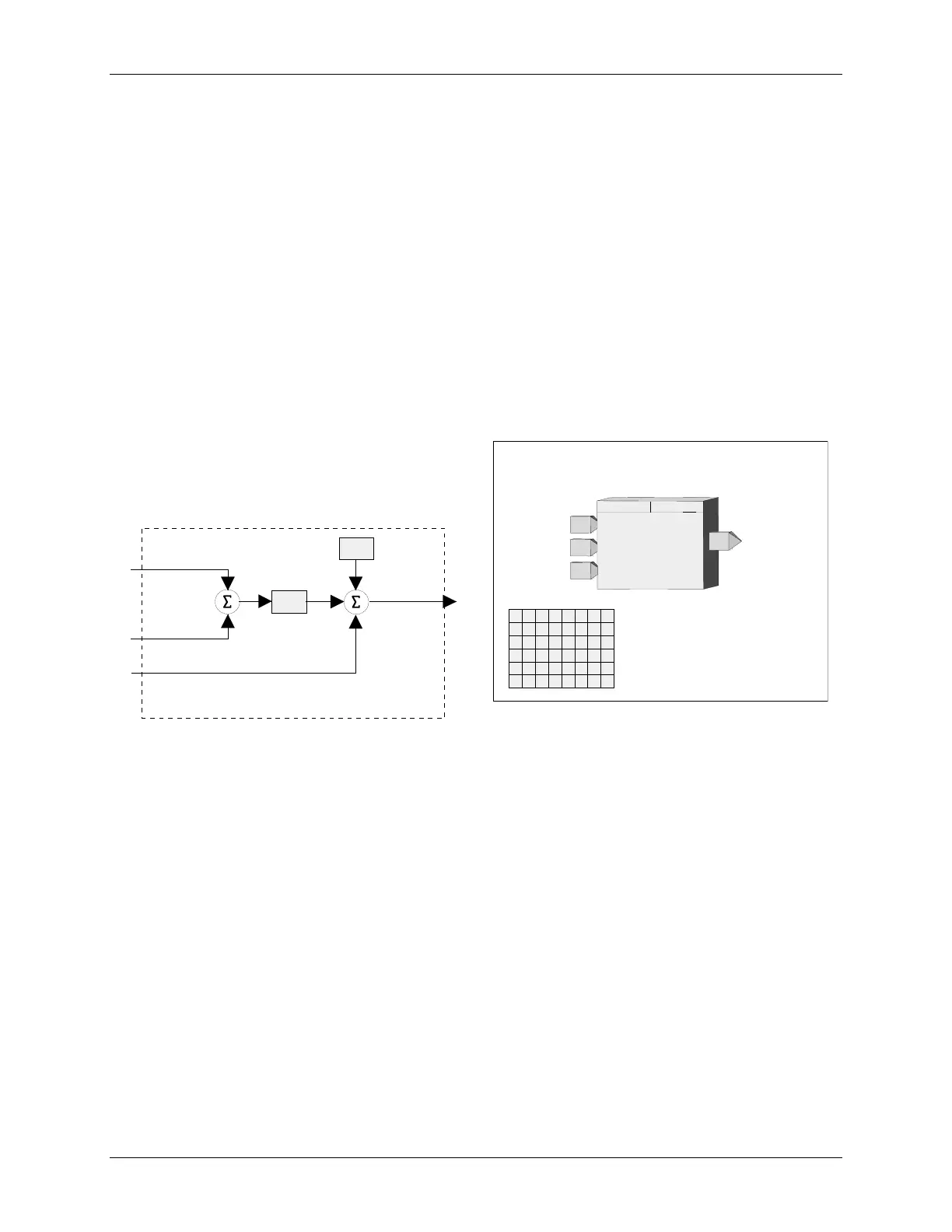

DEVIATION AMPLIFIER

NG

I

N

U

C

GAIN

(S)

.................................... Real (1.0)

BIAS

(S)

..................................... Real (0.0)

INPUT C

(H)

.....

loop tag.block tag.output (null)

O1`

O

utput

1

DEVIATION

DAM_

ESN =

000

I

A

T

P

A

B

A

I

S

ESN

E

xec.

S

eq.

N

o.

(H)

............ 001 to 250

AMPLIFIER

Input

B

B

Input

C

C

I

N

U

AT

P

I

N

U

BT

P

INPUT B

(H)

.....

loop tag.block tag.output (null)

INPUT A

(H)

.....

loop tag.block tag.output (null)

Loading...

Loading...