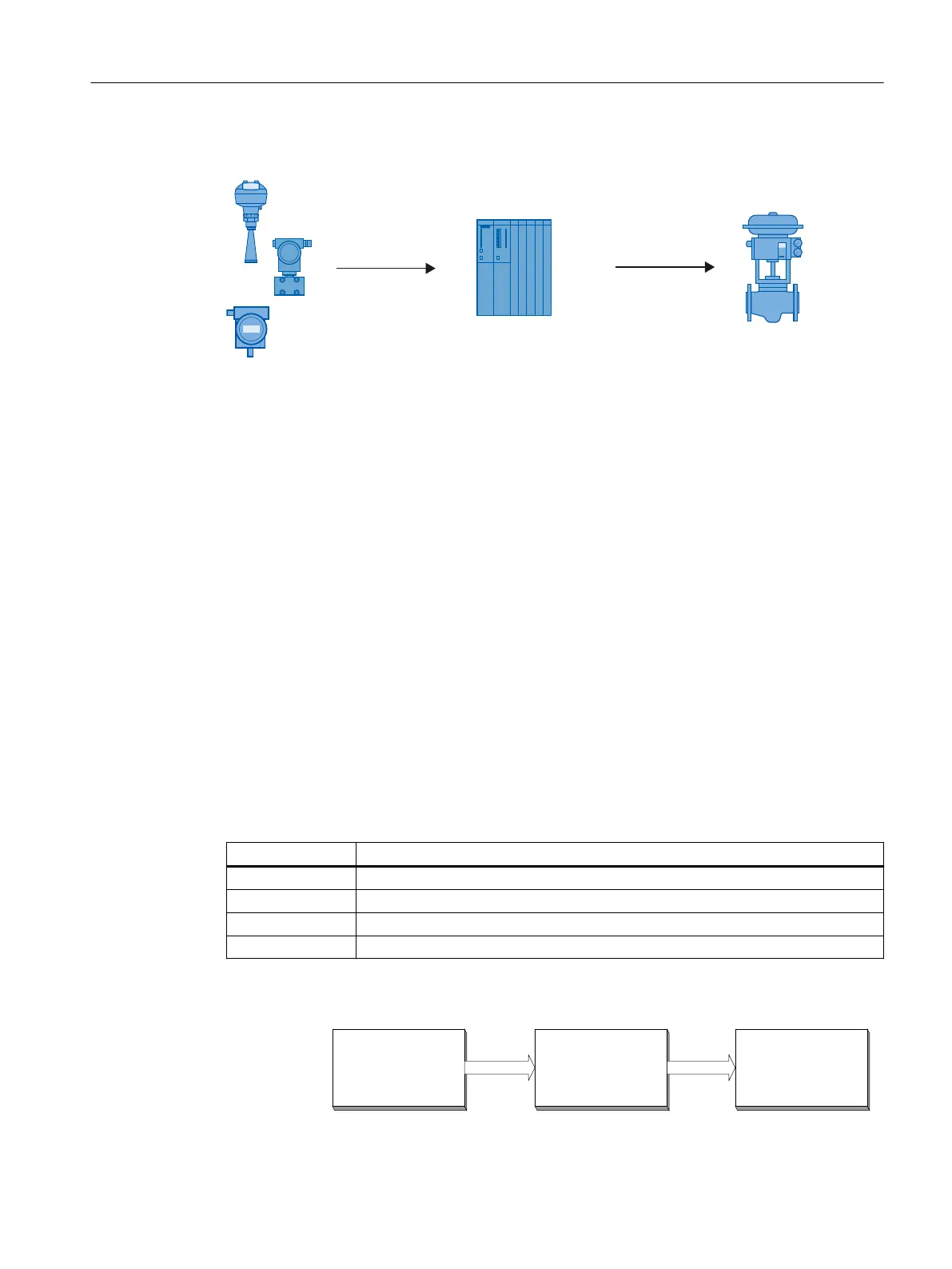

Safety-instrumented system in single-channel operation (SIL 2)

0HDVXUHG

YDOXH

6KXWGRZQVLJQDO

Automation system

Transmitter

Final controlling element

Figure 9-2 Safety-instrumented system in single-channel operation

The combination of transmitter, automation system and final controlling element forms a safety-

instrumented system that performs a safety function.

The transmitter generates a process-related measured value that is transferred to the

automation system. The automation system monitors this measured value. If the measured

value violates the high or low limit, the automation system generates a shutdown signal for the

connected final controlling element, which switches the corresponding process valve to the

specified safety position.

9.3 Safety Integrity Level (SIL)

The international standard IEC 61508 defines four discrete Safety Integrity Levels (SIL) from

SIL 1 to SIL 4. Each level corresponds to a range of probability for failure of a safety function.

Description

The following table shows the dependency of the SIL on the "average probability of dangerous

failure of a safety function of the entire safety-instrumented system" (PFD

AVG

). "Low demand

mode" is examined. The safety function is required a maximum of once per year on average.

Table 9-1 Safety Integrity Level

SIL Interval

4 10

-5

≤ PFD

AVG

< 10

-4

3 10

-4

≤ PFD

AVG

< 10

-3

2 10

-3

≤ PFD

AVG

< 10

-2

1 10

-2

≤ PFD

AVG

< 10

-1

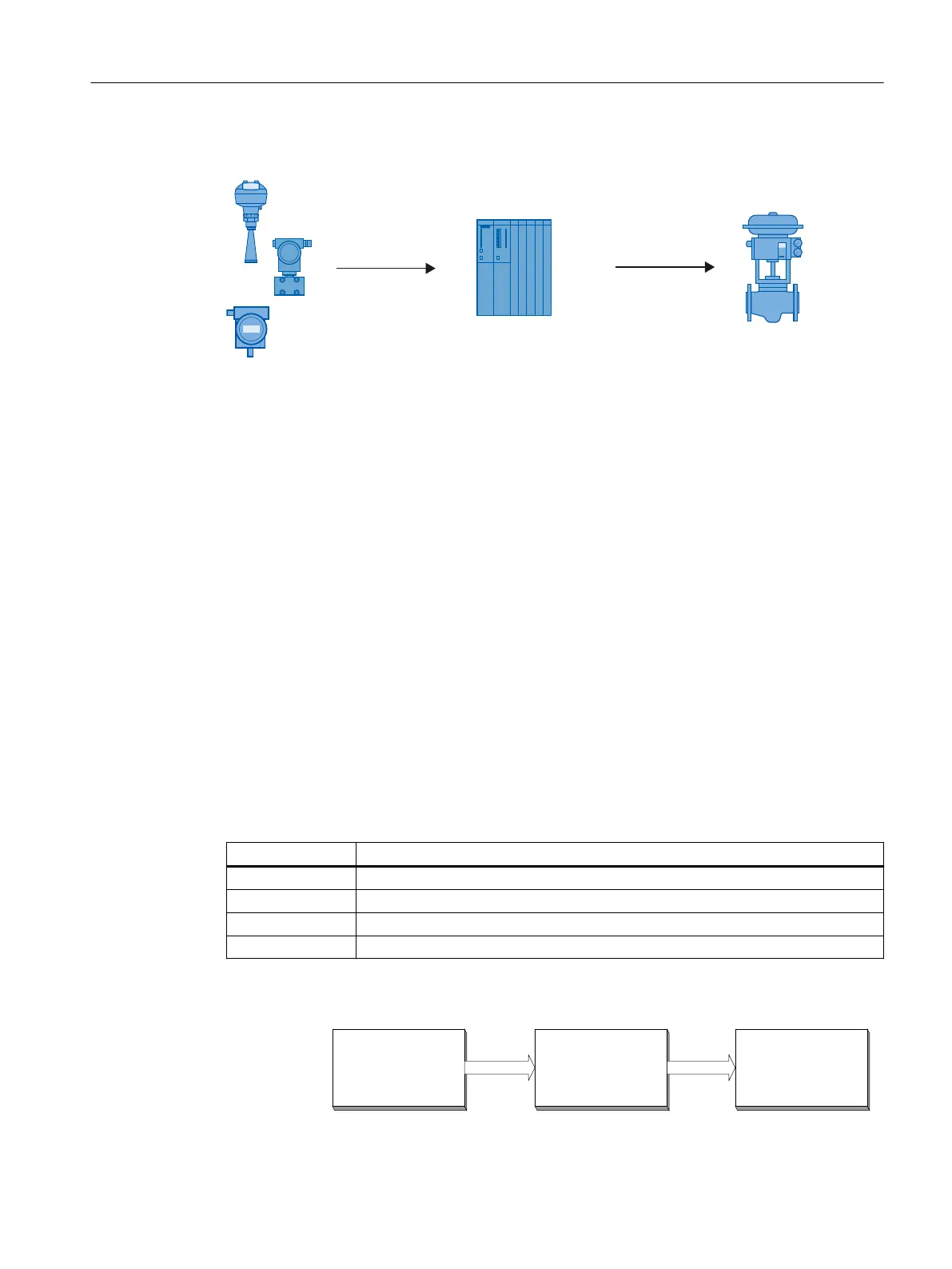

The "average probability of dangerous failure of the entire safety-related system" (PFD

AVG

) is

normally split between the following three components:

7UDQVPLWWHU$XWRPDWLRQ

V\VWHP

)LQDOFRQWUROOLQJ

HOHPHQW

3)'$9*3DUW

Functional safety

9.3 Safety Integrity Level (SIL)

SIPART PS2 with 4 to 20 mA/HART

Operating Instructions, 11/2019, A5E00074631-AE 193

Loading...

Loading...