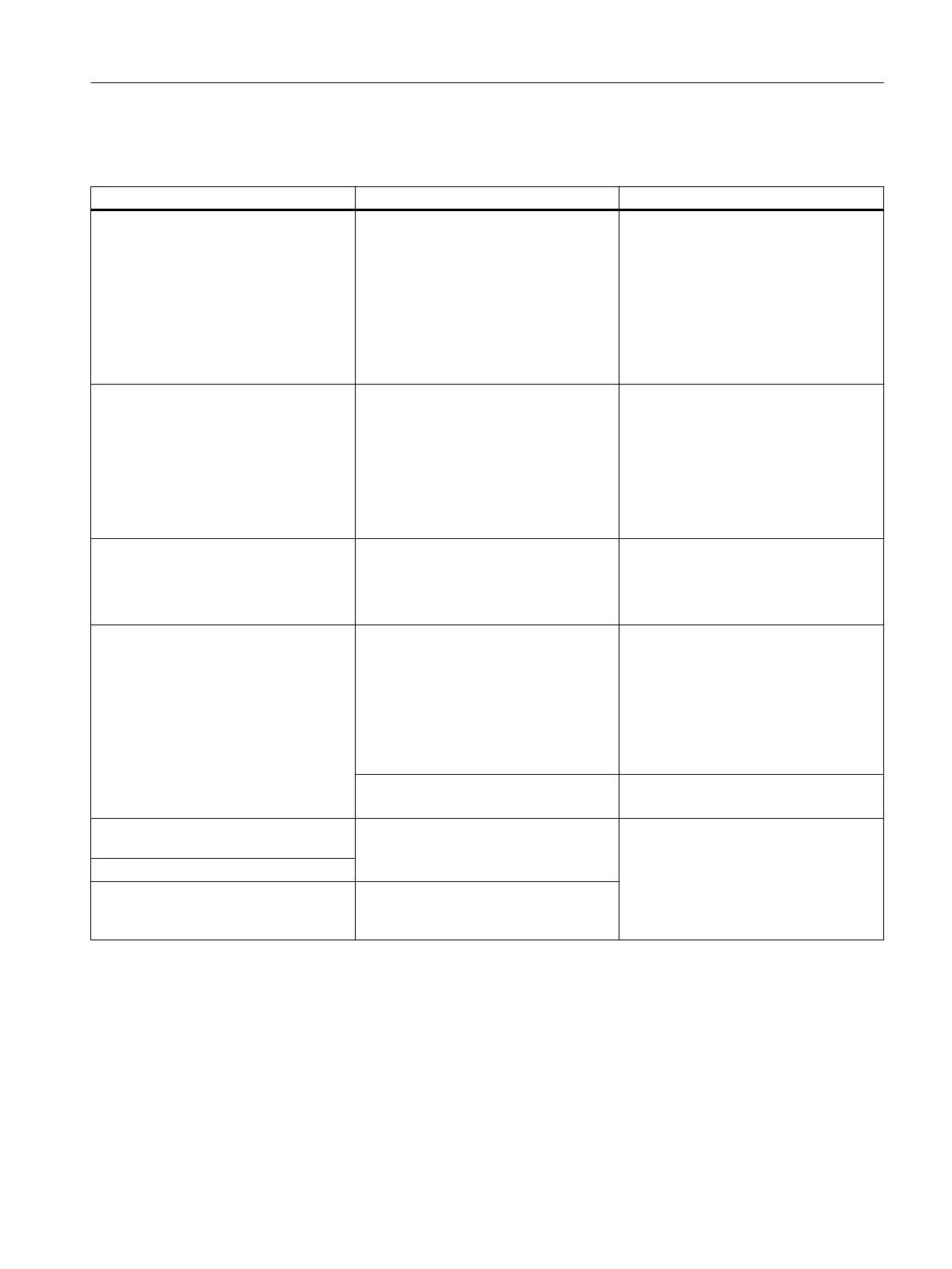

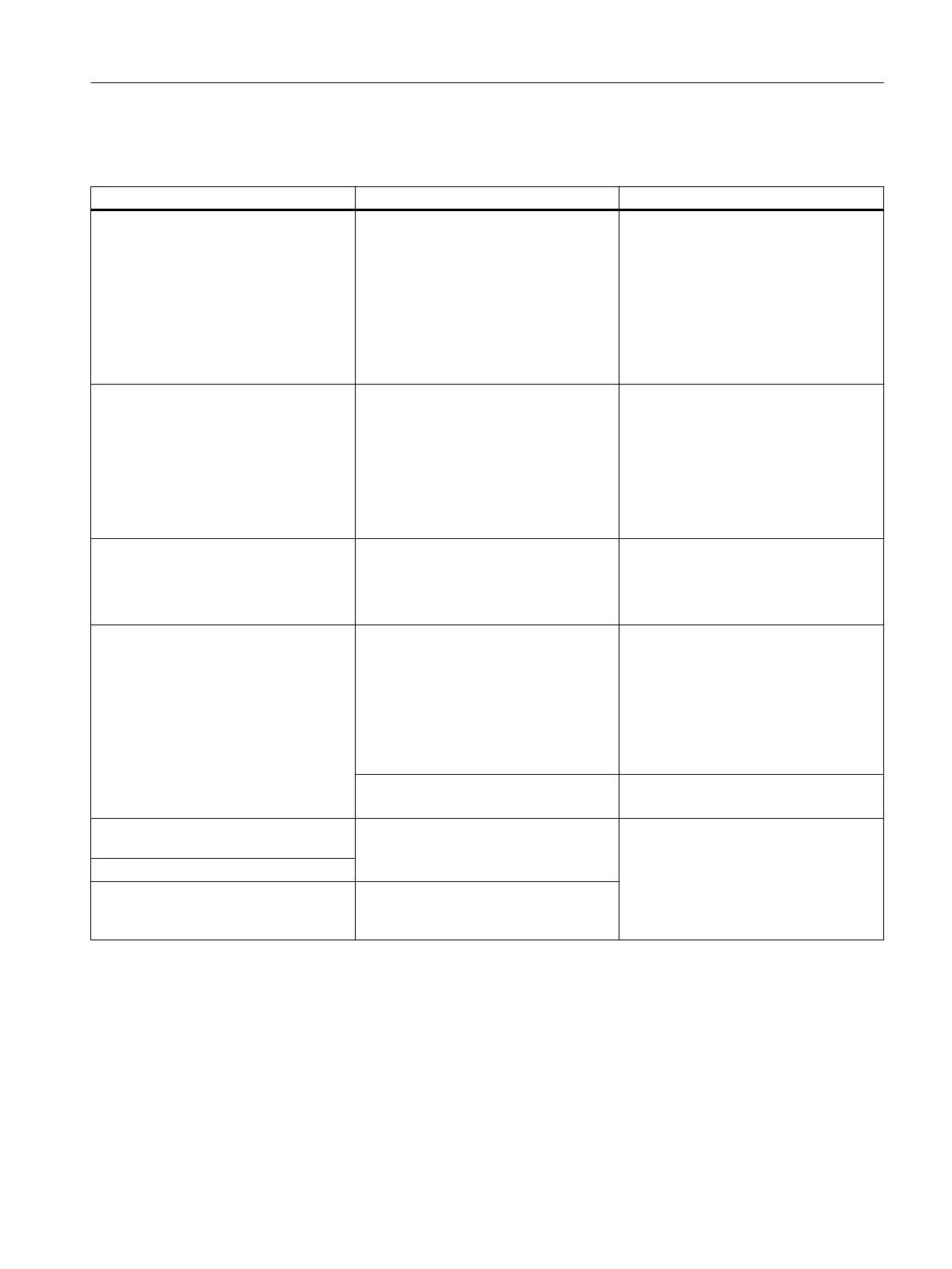

11.4 Fault and remedy

Fault profile (symptoms) Possible cause(s) Remedy

Positioner remains in "RUN 1".

● Initialization started from the end po‐

sition

● The response time of a maximum of

1 minute was not observed

● Supply pressure PZ not connected

or supply pressure PZ too low.

● Compressed air line blocked, e.g.

solenoid valve

● A waiting time of up to 1 minute is

required

● Do not start initialization from the

end position.

● Ensure supply pressure PZ.

● Free up blocked lines

Positioner remains in "RUN 2".

● Transmission ratio selector and pa‐

rameter 2

● "YAGL" and the real stroke do not

match.

● Incorrectly set stroke on the lever

● The pneumatic block does not

switch.

● Check settings: Parameters 2 and 3

● Check the stroke setting on the lever

Positioner remains in "RUN 3".

● Actuator travel time is too high ● Open the restrictor completely

and/or set supply pressure PZ to the

highest permissible value.

● Use a booster if required.

Positioner remains in "RUN 5", does not

go to "FINISH" (waiting time > 5 min.).

● "Gap" (play) in the positioner - ac‐

tuator - control valve system

● Part-turn actuator: Check for firm

seating of set screw on coupling

wheel

● Linear actuator: Check for firm seat‐

ing of lever on positioner shaft.

● Correct any other play between the

actuator and the control valve.

● Diagnostic value "9.TUP" or

"10.TDOWN" < 1.5 s

● Set the traversing velocity to > 1.5 s

using the internal restrictor.

"CPU test" flashes on the local display

approximately every 2 seconds.

● Water in the pneumatic block (due to

wet compressed air)

● At an early stage, this fault can be

rectified with subsequent operation

using dry air, in a temperature cabi‐

net at 50 to 70 °C if required.

● Otherwise: Repair

The pneumatic block does not switch.

In the manual and automatic modes, the

actuator cannot be moved or can be

moved only in one direction.

● Moisture in the pneumatic block

Diagnostics and troubleshooting

11.4 Fault and remedy

SIPART PS2 with 4 to 20 mA/HART

Operating Instructions, 11/2019, A5E00074631-AE 235

Loading...

Loading...