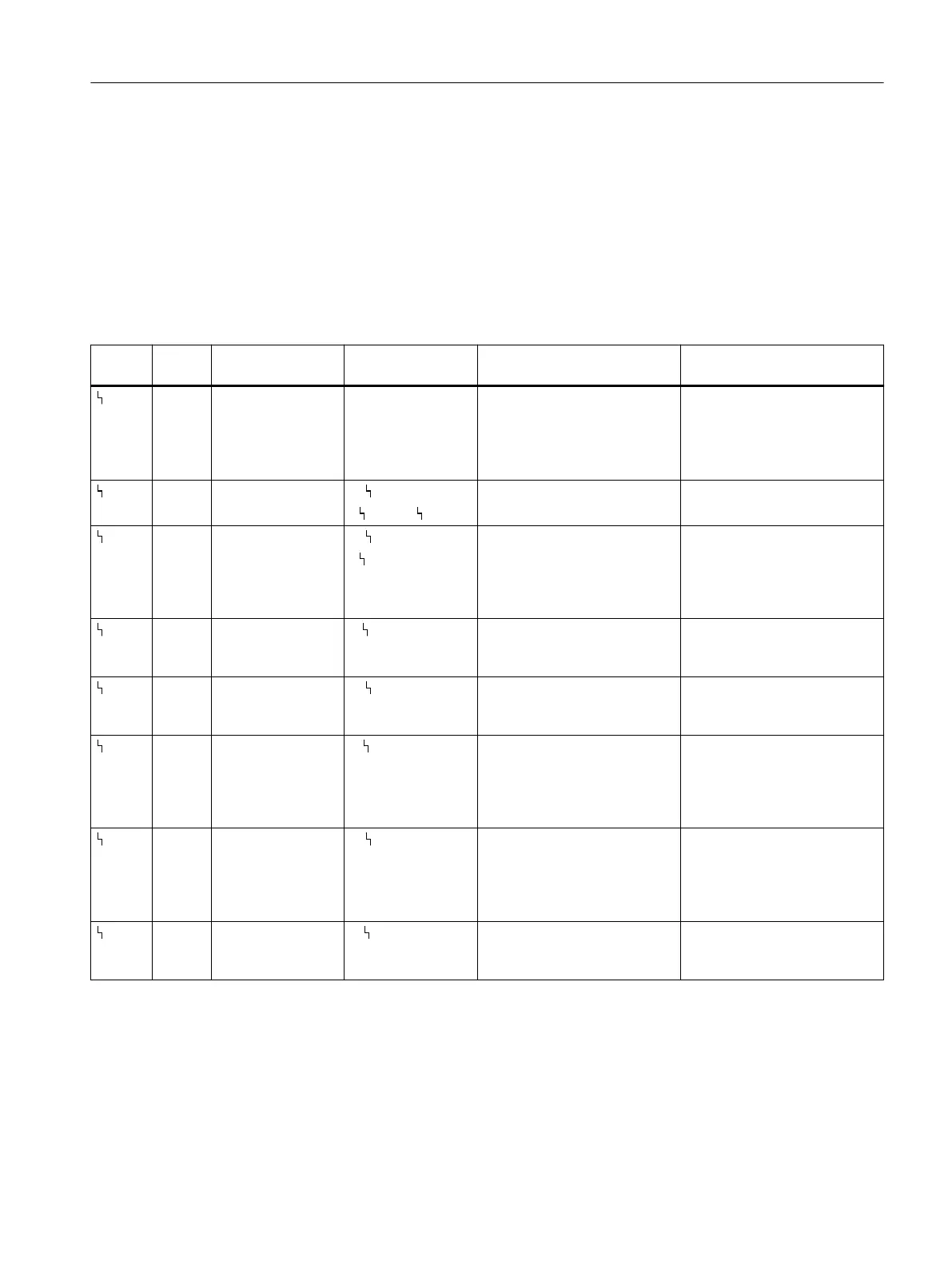

11.3 Online diagnostics

11.3.1 Overview of error codes

Overview of error codes that activate the fault message output

You can find where the error codes are output in the display under "52.XDIAG (Page 162)".

Error

code

Three-

stage

Event Parameter setting Error message disappears

when

Possible causes

1 No Control deviation:

Actual value re‐

sponse has excee‐

ded values for TIM

and LIM

Always active ... the actual value response

falls below the value for LIM

Supply pressure PZ missing,

actuator fault, process valve

fault (e.g. blockage).

2 No Device not in "Au‐

tomatic" mode

**. FCT

1)

= nA or = nAB

... the device is changed to

"Automatic" mode.

The device has been config‐

ured or is in the manual mode

3 No Digital input BIN1

or BIN2 active

**. FCT

1)

= nAB and digital

function BIN1 or

BIN2 to "On"

... the digital input is no longer

activated.

The contact connected to the

digital input was active (e.g.

packing gland monitoring,

overpressure, temperature

switch).

4 Yes Limit for number of

total strokes ex‐

ceeded

L. STRK≠OFF ... the stroke counter is reset

or the thresholds are in‐

creased

The total path covered by the

actuator exceeds one of the

configured thresholds.

5 Yes Limit for number of

changes in direc‐

tion exceeded

O. DCHG≠OFF ... the counter for changes of

direction is reset or the thresh‐

olds are increased.

The number of changes of di‐

rection exceeds one of the

configured thresholds.

6 Yes Lower endstop lim‐

it exceeded

F. ZERO≠OFF

**.YCLS = do or up

do

... the deviation of the endstop

disappears or the device is re-

initialized.

Wear and tear of the process

valve, deposits or foreign bod‐

ies in the process valve, me‐

chanical misalignment, fric‐

tion clutch moved.

7 Yes Upper endstop lim‐

it exceeded

G. OPEN≠OFF

**.YCLS

1)

= do or

up do

... the deviation of the endstop

disappears or the device is re-

initialized.

Wear and tear of the process

valve, deposits or foreign bod‐

ies in the process valve, me‐

chanical misalignment, fric‐

tion clutch moved.

8 No Deadband limit ex‐

ceeded

E. DEBA≠OFF

**.DEBA

1)

= Auto

... the limit is undershot again Increased packing gland fric‐

tion, mechanical gap in the po‐

sition feedback.

Diagnostics and troubleshooting

11.3 Online diagnostics

SIPART PS2 with 4 to 20 mA/HART

Operating Instructions, 11/2019, A5E00074631-AE 229

Loading...

Loading...