111MS 201, MS 201 C, MS 201 T, MS 201 TC

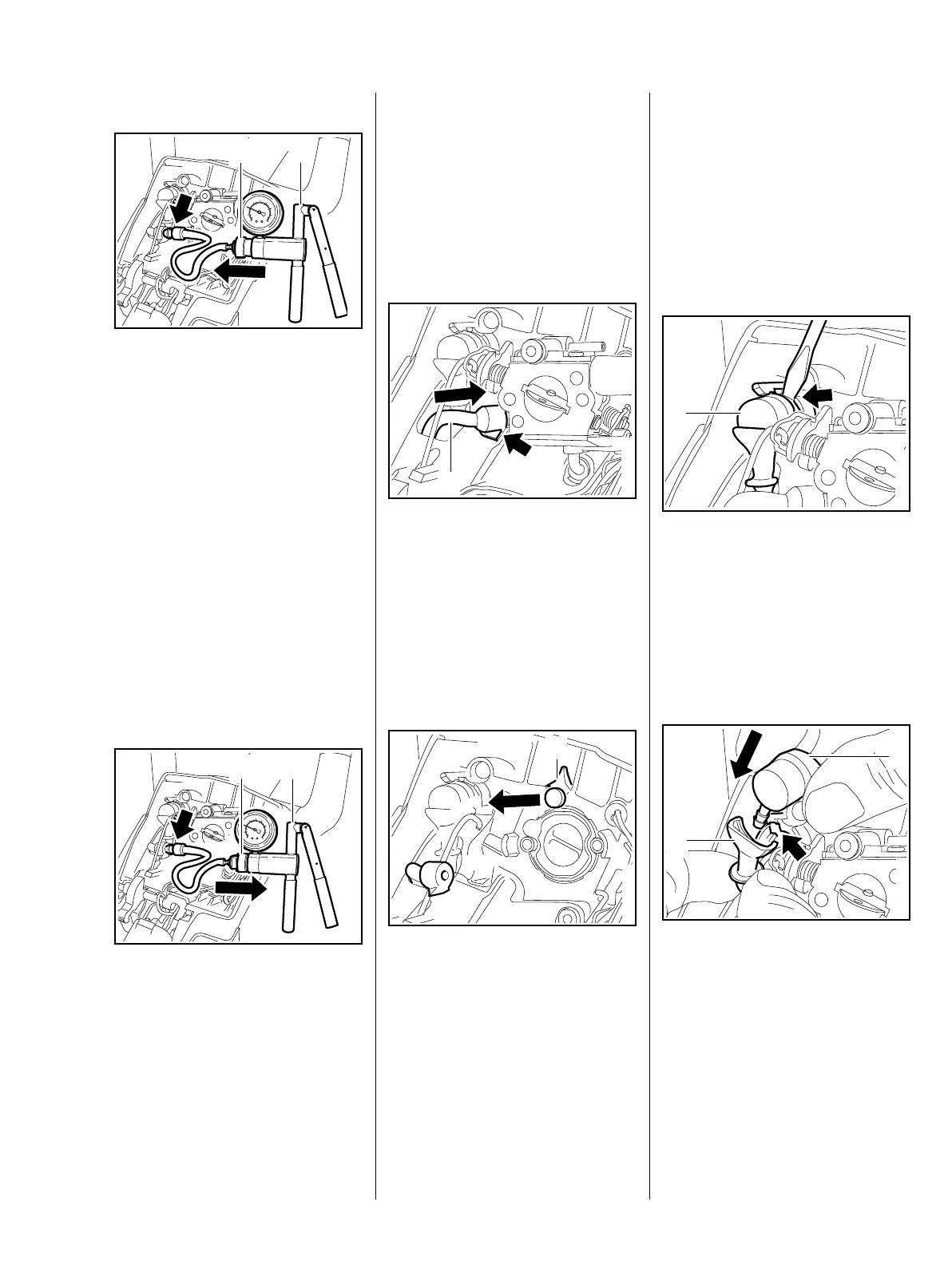

Vacuum test

: Push the ring (1) to the left and

connect the pump (2)

0000 850 1300 to the nipple

(arrow)

– subject the fuel tank to a

vacuum.

Equalization of pressure takes

place via the tank vent. There must

be no buildup of vacuum in the tank.

– Clean the area around the tank

vent.

– Install new tank vent if necessary

MS 201 b 12.9.2,

MS 201 T b 12.9.3

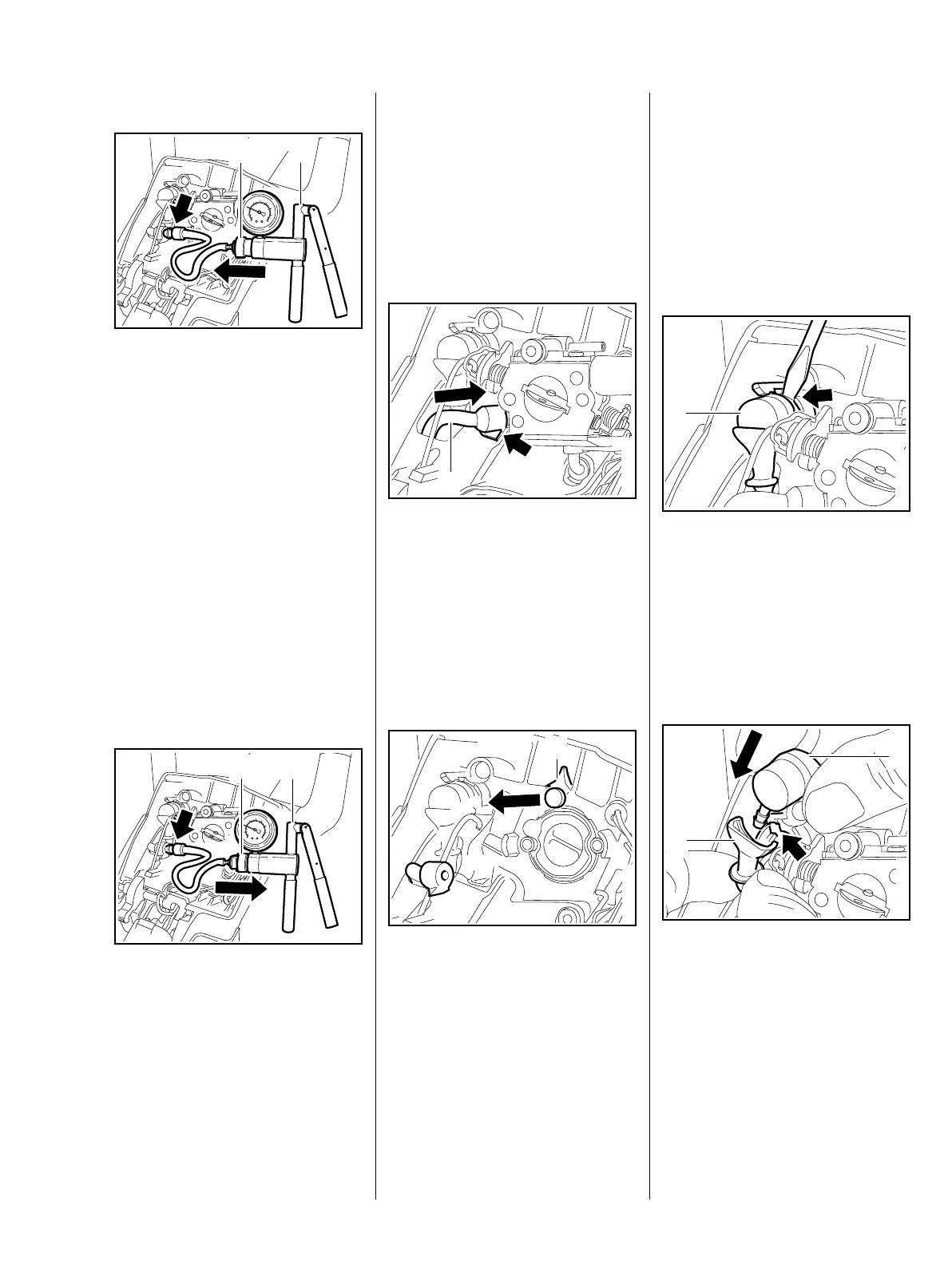

Pressure test

: Push the ring (1) to the right and

connect the pump (2)

0000 850 1300 to the nipple

(arrow)

– pressurize the fuel tank.

2

1

7013RA265 TG

2

1

7013RA266 TG

– Operate the pump until the

pressure gauge indicates a

pressure of 0.5 bar. If this

pressure remains constant for at

least 20 seconds, the tank,

including the tank vent, is airtight.

If the pressure drops, the leak

must be located and the faulty

part replaced.

– Pull the nipple out of the fuel

suction hose.

: Push the fuel suction hose (1)

onto the nipple so that the tab

matches the contour (arrow) of

the handle housing.

Models with manual fuel pump

: Pull plug out of fuel suction

hose (1).

– Install the carburetor,

MS 201 b 12.4,

MS 201 T b 12.5

7013RA267 TG

1

7013RA463 TG

1

All models

– Reassemble all other parts in the

reverse sequence.

12.9.2 Tank Vent (MS 201)

– Remove the filter base, b 12.3

: Use a screwdriver to pry out the

tank vent (1) at the recess

(arrow).

– Pull the tank vent (1) out of the

hose.

Always install a new tank vent.

– Position the new tank vent (1) so

that it points toward the seat.

: Push the tank vent (1) into the

vent hose (2) and into its seat

(arrow) as far as stop.

– Reassemble all other parts in the

reverse sequence.

7013RA268 TG

1

7013RA269 TG

1

2

Loading...

Loading...