91MS 201, MS 201 C, MS 201 T, MS 201 TC

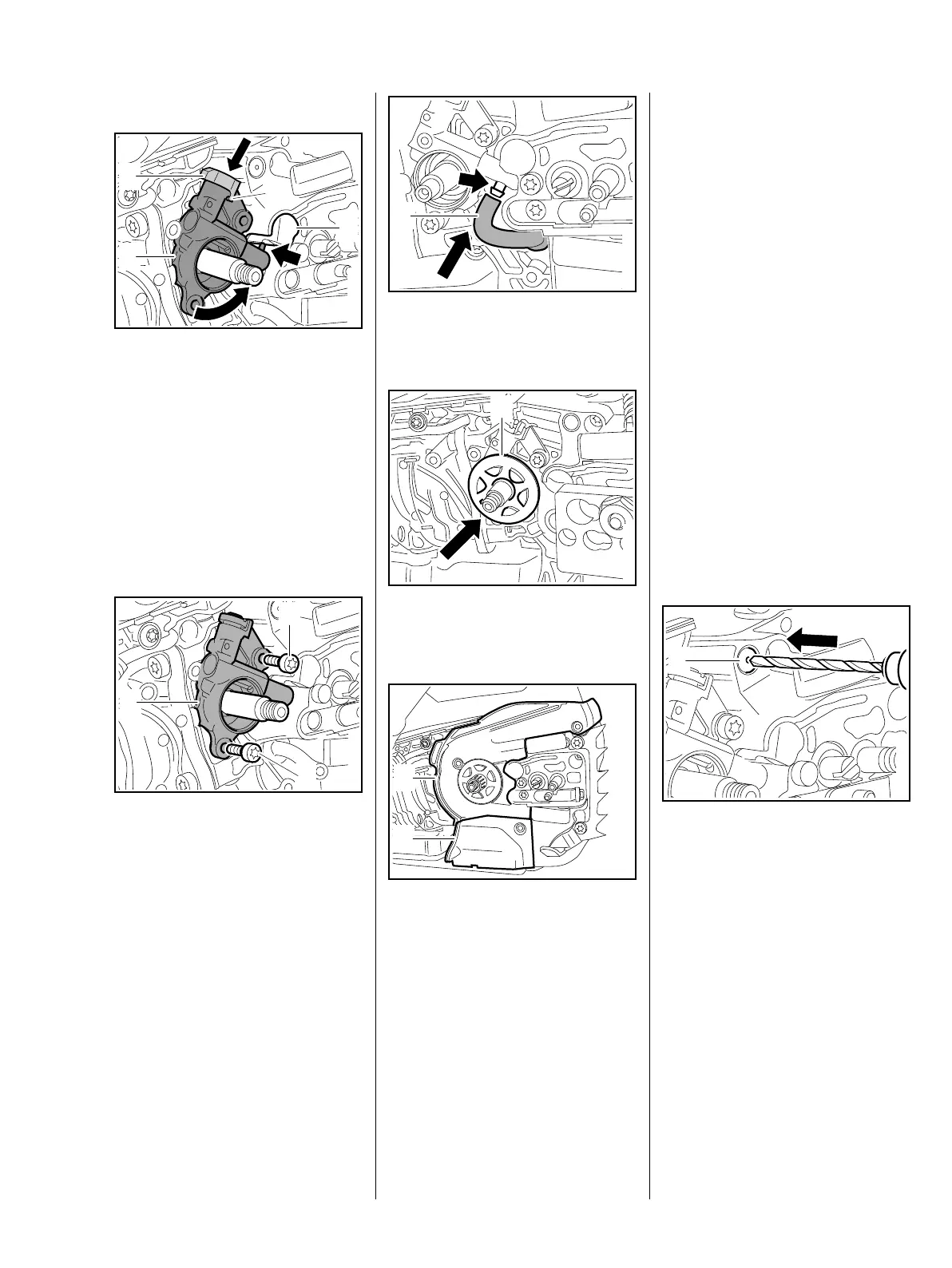

MS 201 T

: Push on the grommet (3) as far

as stop and fit tab (4) under the

oil pump's shoulder.

: Place the oil pump (1) in position

and turn it counterclockwise until

the stub (arrow) is properly

seated in the connector's

bore (2).

All models

: Line up the oil pump (1) with the

holes.

: Insert and tighten down the

screws (2) firmly.

7013RA528 TG

1

3

2

4

7013RA104 TG

1

2

2

: Push the oil suction hose (1) onto

the oil pump's stub (arrow).

: Push the worm (1) into the oil

pump.

: Place the cover (1) in position.

: Slide cover (2) into cover (1) first,

then press the underside into the

crankcase until it snaps into

place.

– Fit the screws and tighten them

down firmly.

– Reassemble all other parts in the

reverse sequence.

7013RA105 TG

1

7013RA106 TG

1

7013RA107 TG

1

2

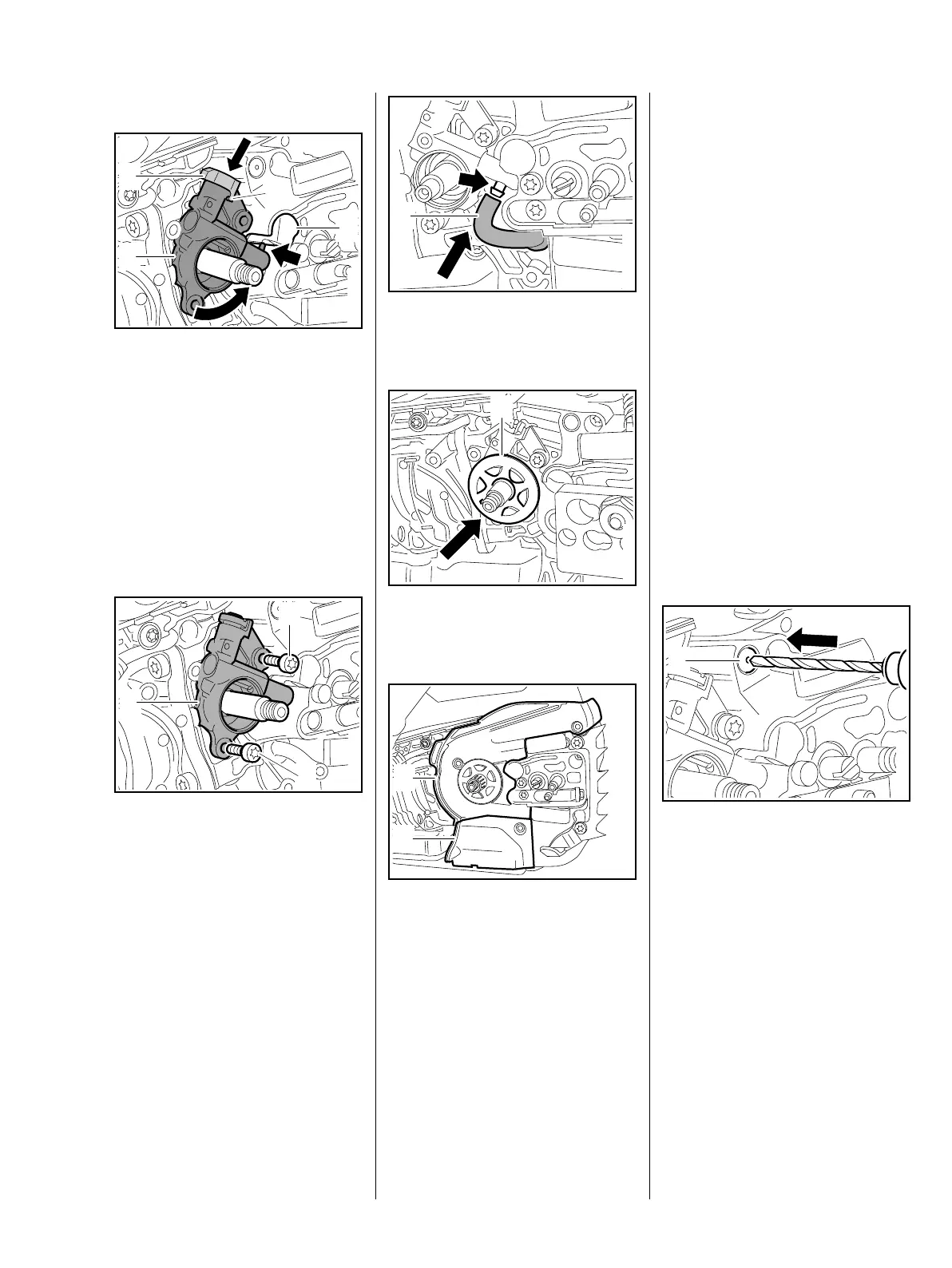

11.5 Valve

A valve is installed in the housing

wall to keep internal tank pressure

equal to atmospheric pressure. The

valve must be replaced if it is faulty.

– Open the oil tank cap and drain

the oil tank.

– Collect chain oil in a clean

container, b 1

– Disengage the chain brake and

remove the chain sprocket cover,

bar and chain.

– Remove the clutch drum, b 4.2

– Remove the cover, b 11.4

The valve has to be pulled out, e.g.

with sleeve 1127 791 7200,

M 4 x 25 mm screw and M 4 nut.

Drill to a depth of no more than

5mm

– no deeper, otherwise the ball,

spring and washer will fall into the

oil tank.

: Drill valve (1) to 3.3 mm diameter

and cut an M 4 thread.

– Clean away drillings. Remove

ball, spring and washer from

inside oil tank if necessary.

7013RA513 TG

1

Loading...

Loading...