59MS 201, MS 201 C, MS 201 T, MS 201 TC

8. Rewind Starter

8.1 General

If the action of the starter rope

becomes very stiff and the rope

rewinds very slowly or not

completely, it can be assumed that

the starter mechanism is in order

but plugged with dirt. At very low

outside temperatures the lubricating

oil on the rewind spring may thicken

and cause the spring windings to

stick together. This has a

detrimental effect on the function of

the starter mechanism.

In such a case it is sufficient to apply

a few drops of a standard solvent-

based degreasant (containing no

chlorinated or halogenated

hydrocarbons) to the rewind spring.

Carefully pull out the starter rope

several times and allow it to rewind

until its normal smooth action is

restored.

Before installing, lubricate the

rewind spring and starter post with

STIHL special lubricant, b 14.

If clogged with dirt or pitch, the

entire starter mechanism, including

the rewind spring, must be removed

and disassembled. Take particular

care when removing the rewind

spring.

– Clean all components.

– Relieve tension of rewind spring,

b 8.4

Models with ErgoStart

– Relieve tension of rewind spring,

b 8.4.1

8.2 Fan Housing

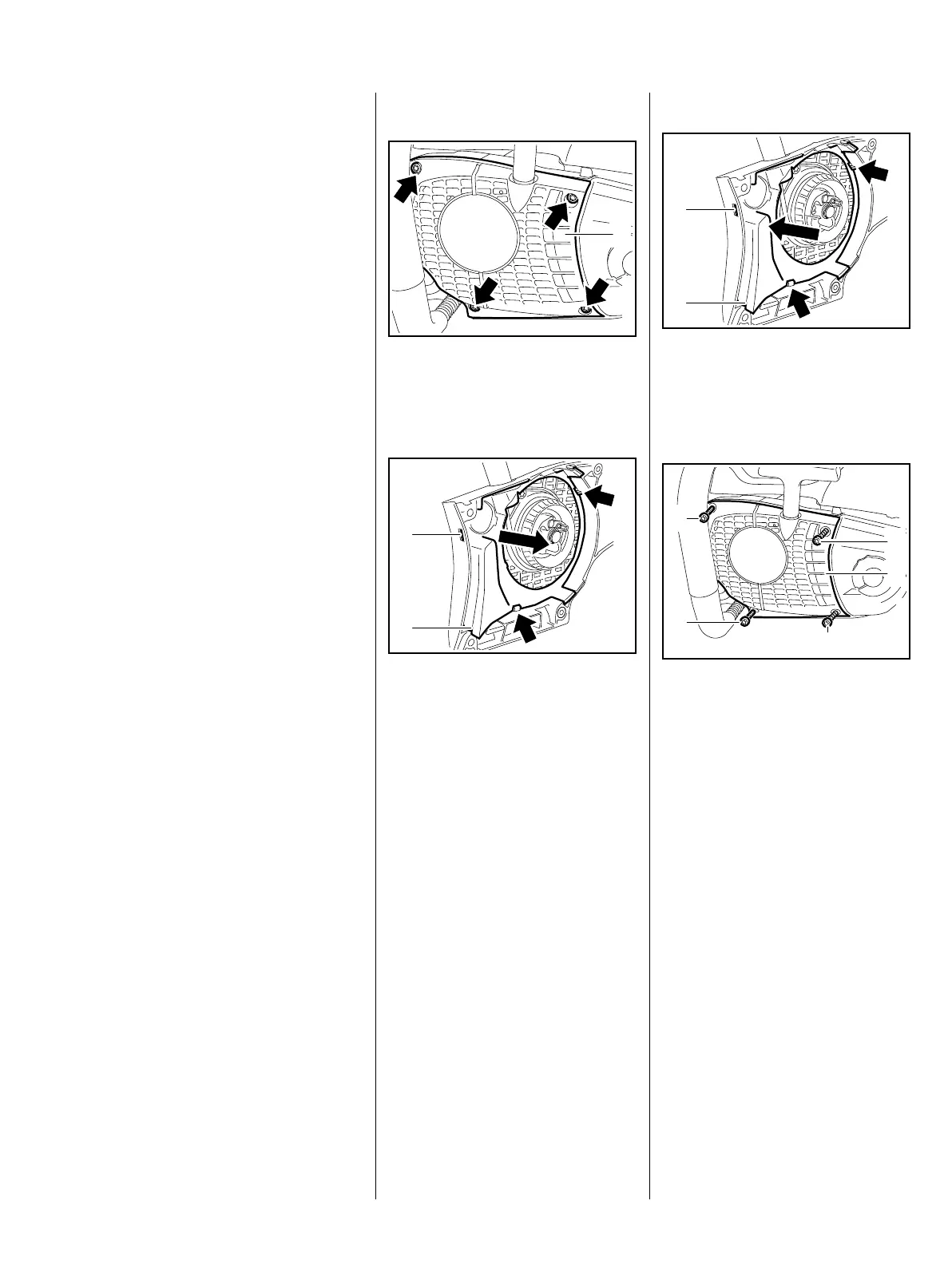

: Take out the screws (arrows).

– Remove the fan housing (1).

: Pry the segment (1) out at the

lug (2), pull it off the tabs (arrows)

and lift it away.

– Examine the fan housing and

segment and replace if

necessary.

7013RA150 TG

1

7013RA151 TG

2

1

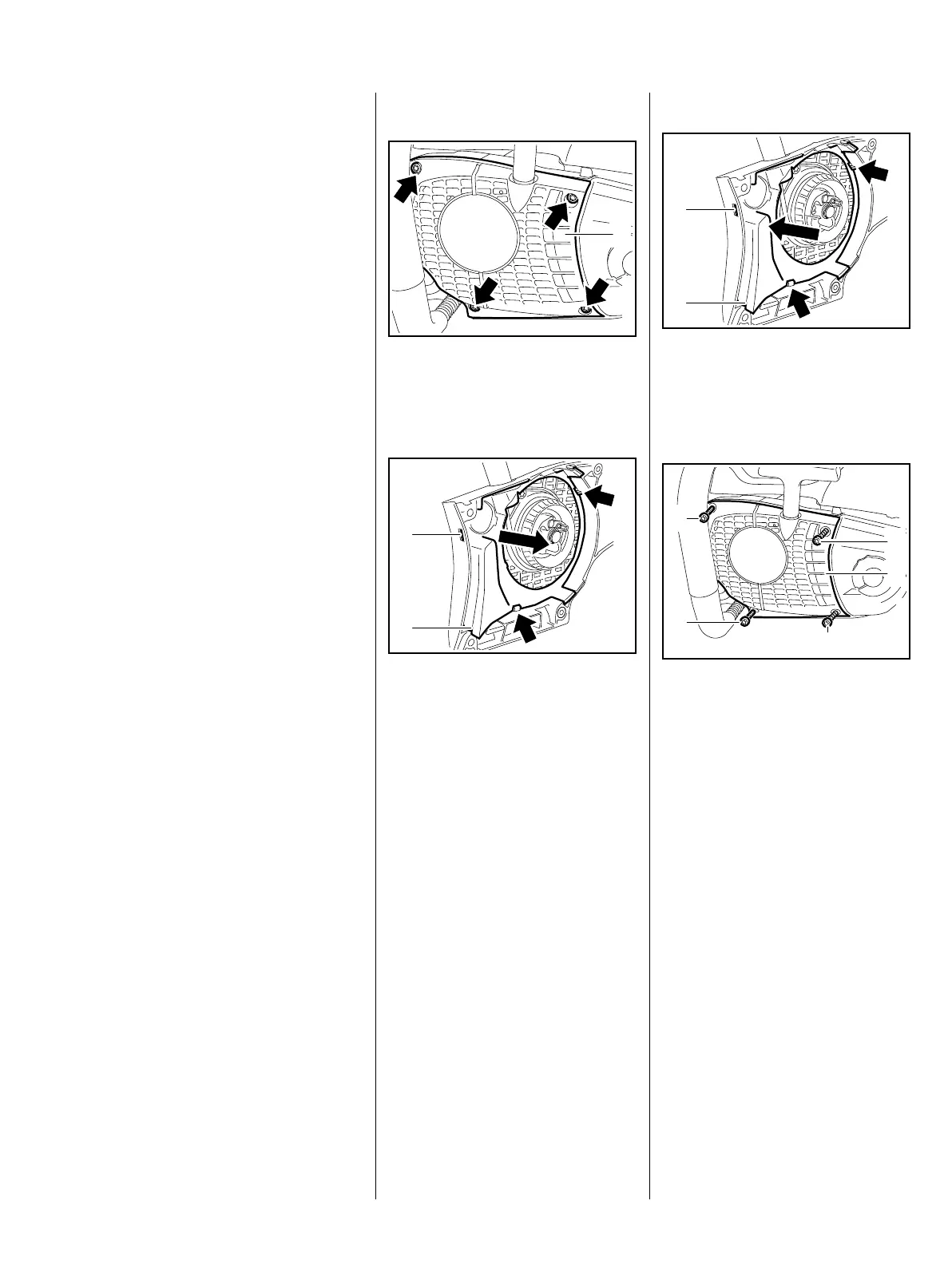

Installing

: Push the segment (1) under the

tabs (arrows) and into the fan

housing until the lug (2) snaps

into place.

: Place the fan housing (1) in

position.

: Insert the screws (2) and

Plastoform screws (3) and

tighten them down firmly.

– Reassemble all other parts in the

reverse sequence.

7013RA153 TG

2

1

7013RA218 TG

1

2

2

3

3

Loading...

Loading...