29MS 201, MS 201 C, MS 201 T, MS 201 TC

6.2 Leakage Test

Defective oil seals and gaskets or

cracks in castings are the usual

causes of leaks. Such faults allow

supplementary air to enter the

engine and upset the fuel-air

mixture.

This makes adjustment of the

prescribed idle speed difficult, if not

impossible.

Moreover, the transition from idle

speed to part or full throttle is not

smooth.

Always perform the vacuum test

first and then the pressure test.

The engine can be checked

thoroughly for leaks with the pump

0000 850 1300.

6.2.1 Preparations

– Disengage the chain brake and

remove the chain sprocket cover,

bar and chain.

The preparations are the same for

the MS 201 and MS 201 T even

though their handle housings and

the position of the carburetor are

different.

– Pull the boot off the spark plug.

: Unscrew the spark plug (1).

– Set the piston to top dead center.

This can be checked through the

spark plug hole.

: Fit the spark plug (1) and tighten

it down firmly.

– Remove the muffler, b 6.1

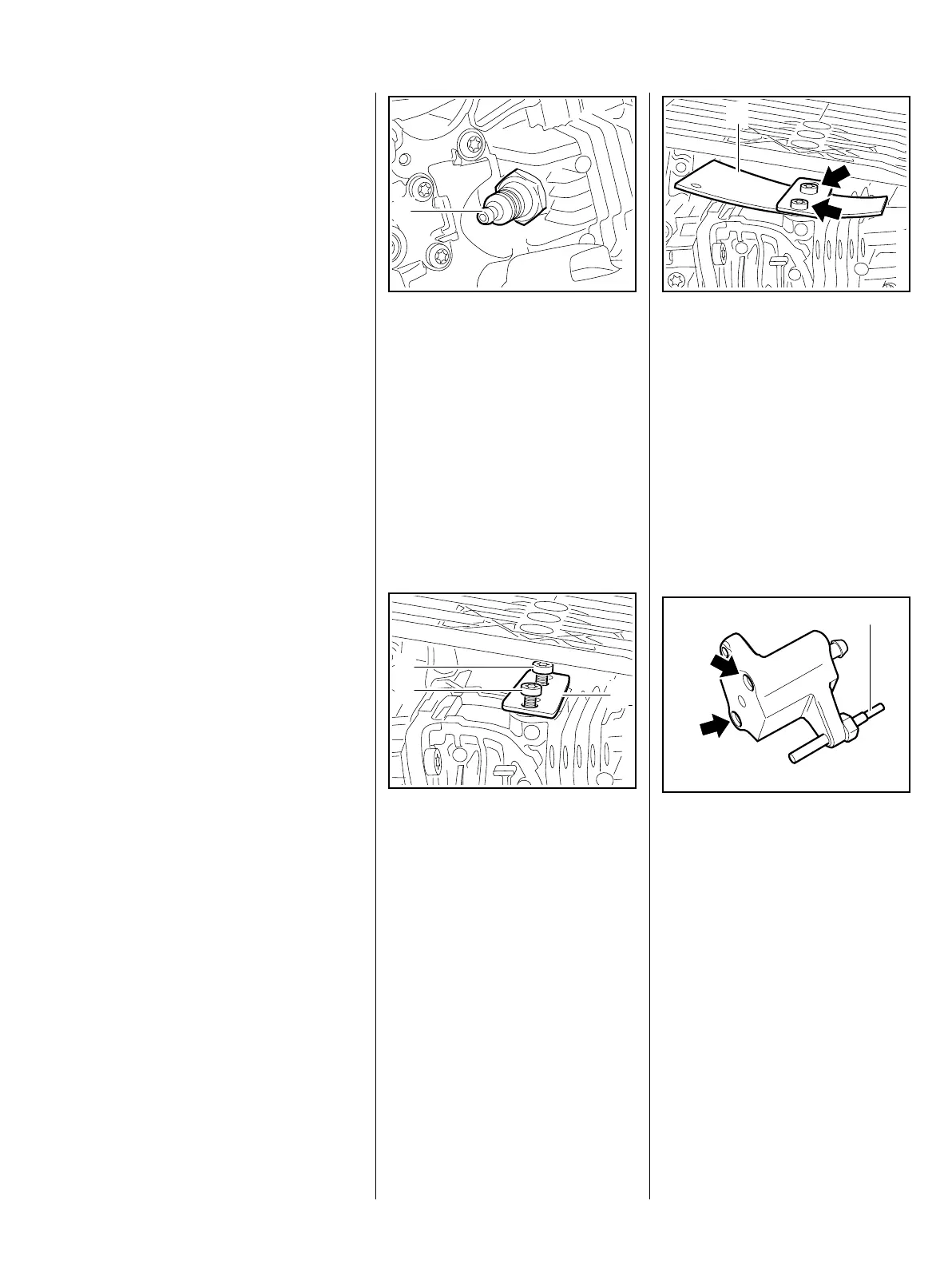

: Fit the test flange (1)

5910 855 4201.

: Fit the screws (2).

7013RA056 TG

1

7013RA057 TG

2

1

2

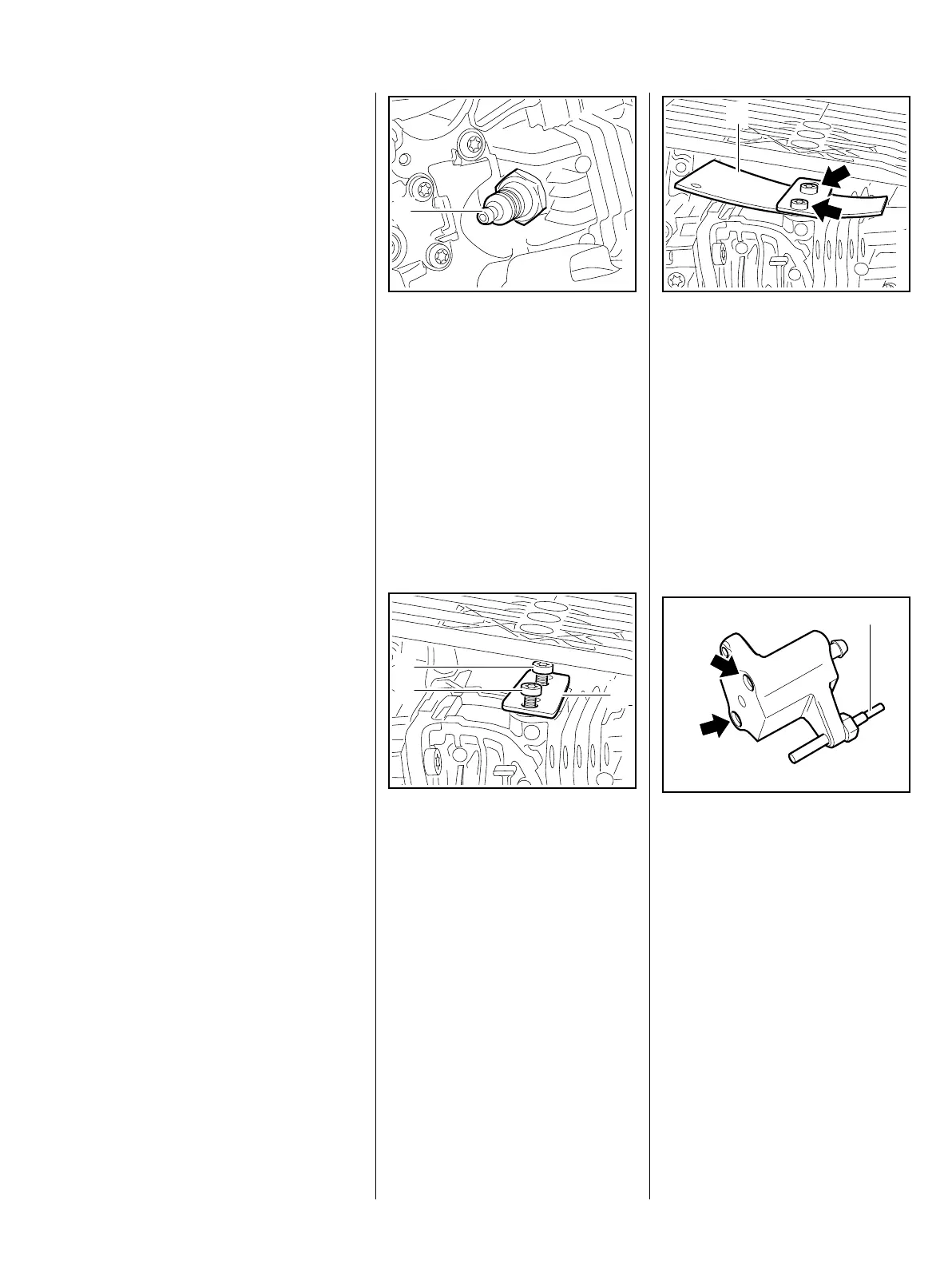

: Slide the sealing plate (1)

0000 855 8106 between the

cylinder exhaust port and flange

and tighten down the screws

(arrows) moderately.

The sealing plate must completely

fill the space between the two

screws.

– Remove the carburetor,

MS 201 b 12.4,

MS 201 T b 12.5

The recesses (arrows) must fit over

the bushings.

Screw (1) must be in place – it seals

the impulse hose.

7013RA058 TG

1

7013RA059 TG

1

Loading...

Loading...