5) If clearance is still out of specification even

after lubrication in step

4),

remove carburetor

from intake manifold and remove idle-up

actuator from carburetor.

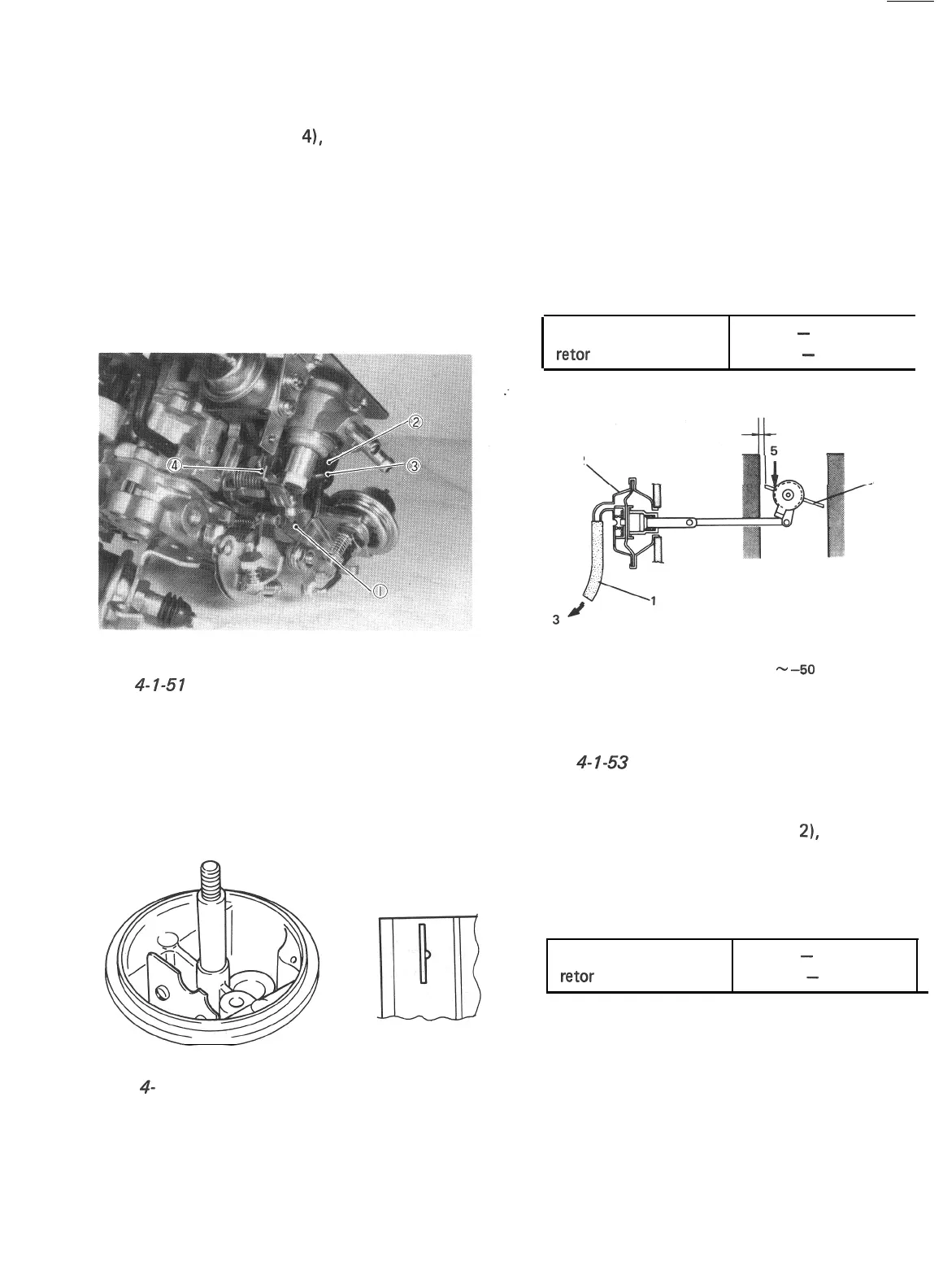

Then, turn fast idle cam counterclockwise and

insert a pin available into holes in cam and

bracket to lock the cam.

In this state, bend choke lever shown in below

figure up or down, with plier. Bending up

causes choke valve to close, and down to

open.

1. Fast idle cam 3. Pin

2. Bracket

4. Choke lever

Fig.

4-

l-51

Choke lever

6) After installing air intake case, start engine

again and warm it up fully.

7)Stop the engine when it is warmed up and

remove air intake case again, and then check

to ensure that choke valve is fully open.

Fig. 4- l-52

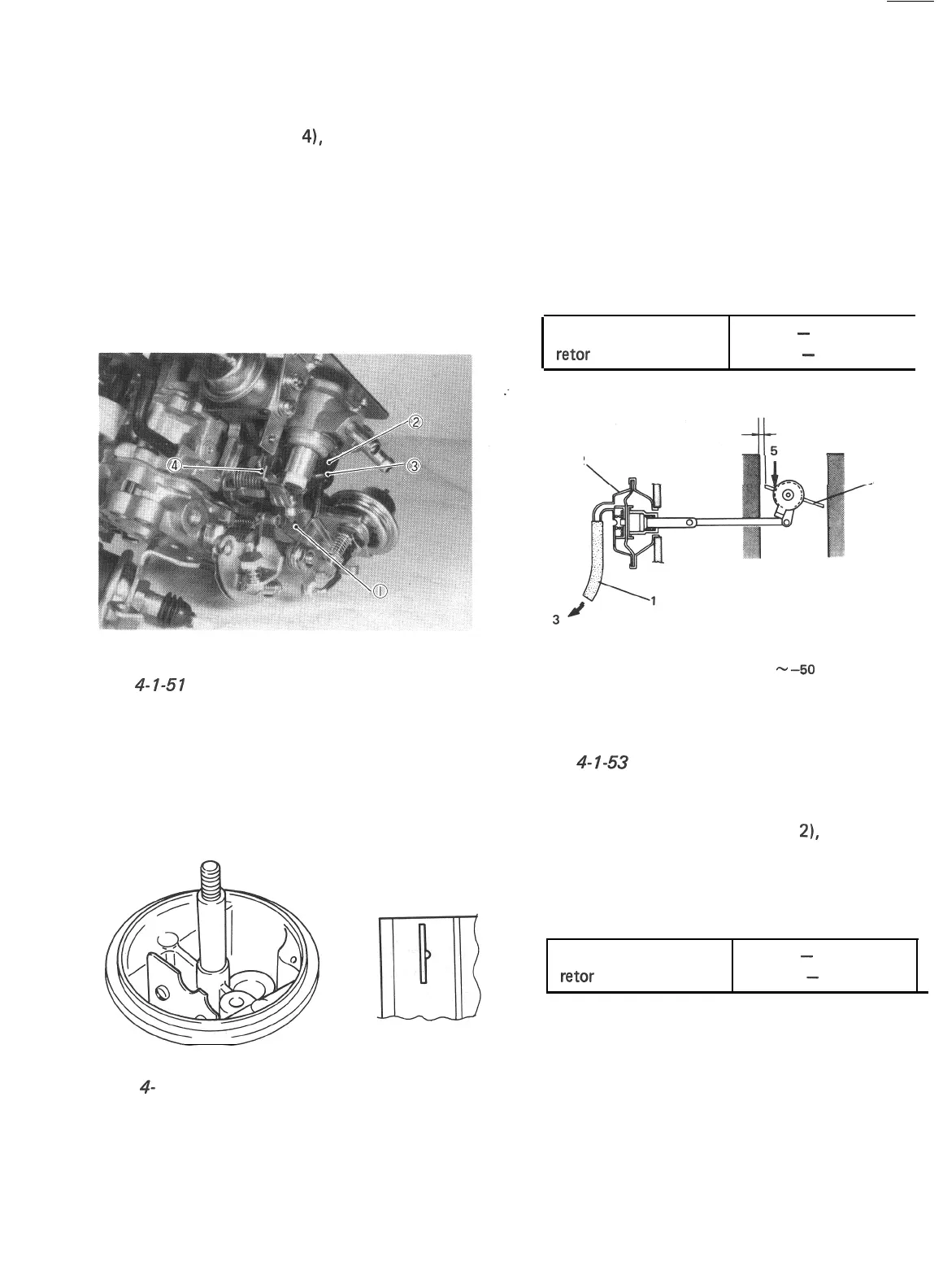

[Choke piston]

Check choke piston as follows.

1) Disconnect choke piston hose at throttle

chamber.

2) With choke valve pushed down to its closing

side lightly by finger, apply vacuum,to choke

piston hose with vacuum pump gauge, and

check to ensure that choke valve to carbure-

tor bore clearance is within the specification.

Choke valve to carbu-

1.1

-

1.3 mm

retor

bore clearance

(0.04

-

0.05 in.)

6

2

4

3/

1. Choke piston hose

2.

Choke piston

3. Vacuum (Apply -30

w-50

cm Hg vacuum)

4.

Choke

valve

5. Push here lightly

6. Choke valve to carburetor bore clearance

Fig. 4-

l-53

Checking choke piston

3) With vacuum appliedas in step

2),

move choke

piston rod with small screw driver as shown

and check to ensure that choke valve to car-

buretor bore clearance is within following

specification.

Choke valve to carbu-

3.2

-

3.7 mm

retor

bore clearance

(0.13

-

0.14 in.)

If choke valve doesn’t open fully, defect lies in

wax-element or its link system.

Repair or replace defective parts(s).

4-23

Loading...

Loading...