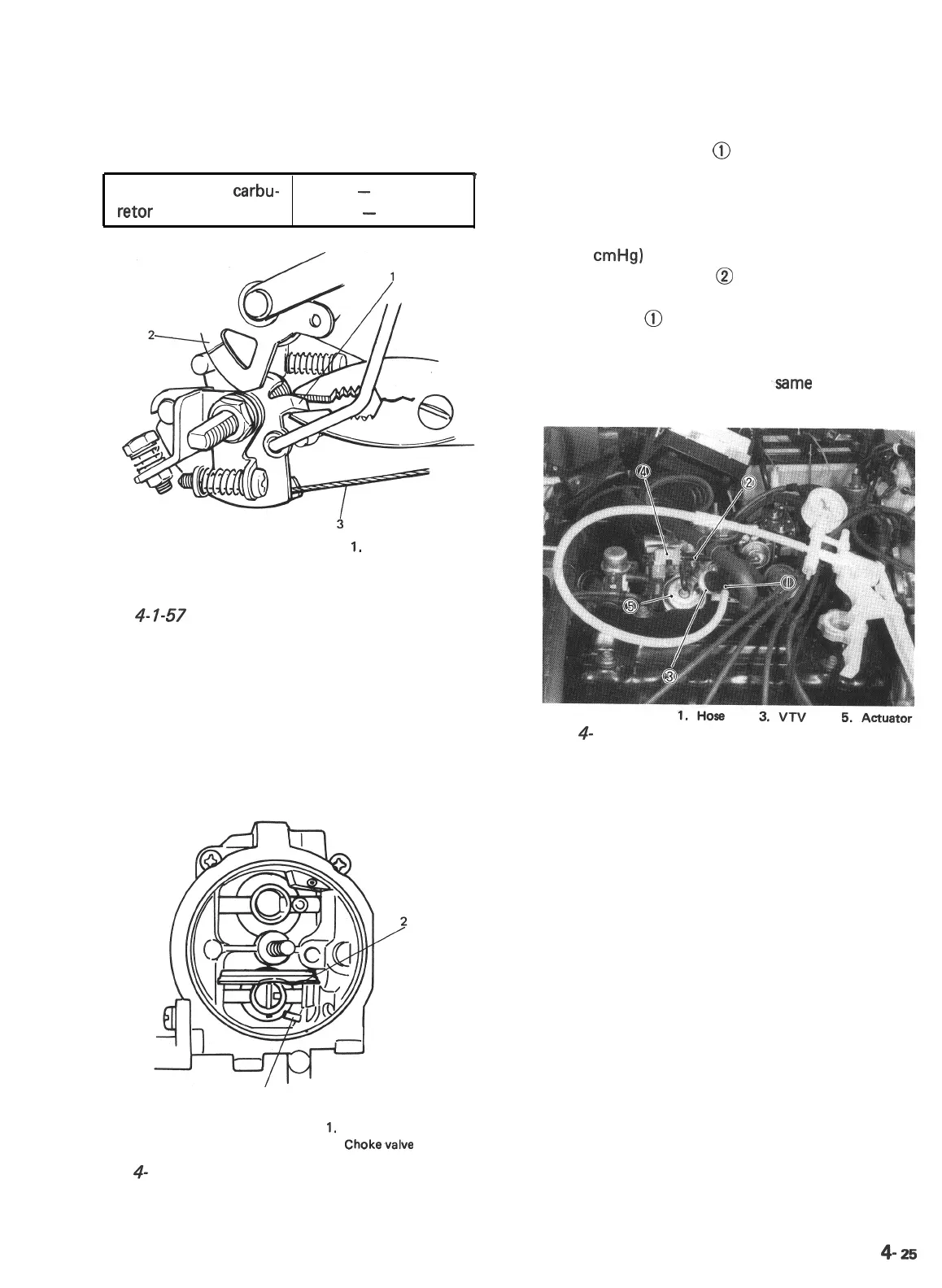

4) If clearance is out of specification, adjust by

bending the unloader arm indicated in below

figure.

‘

Choke valve to

carbu-

2.5

-

3.2 mm

retor bore clearance

(0.10

-

0.12 in.)

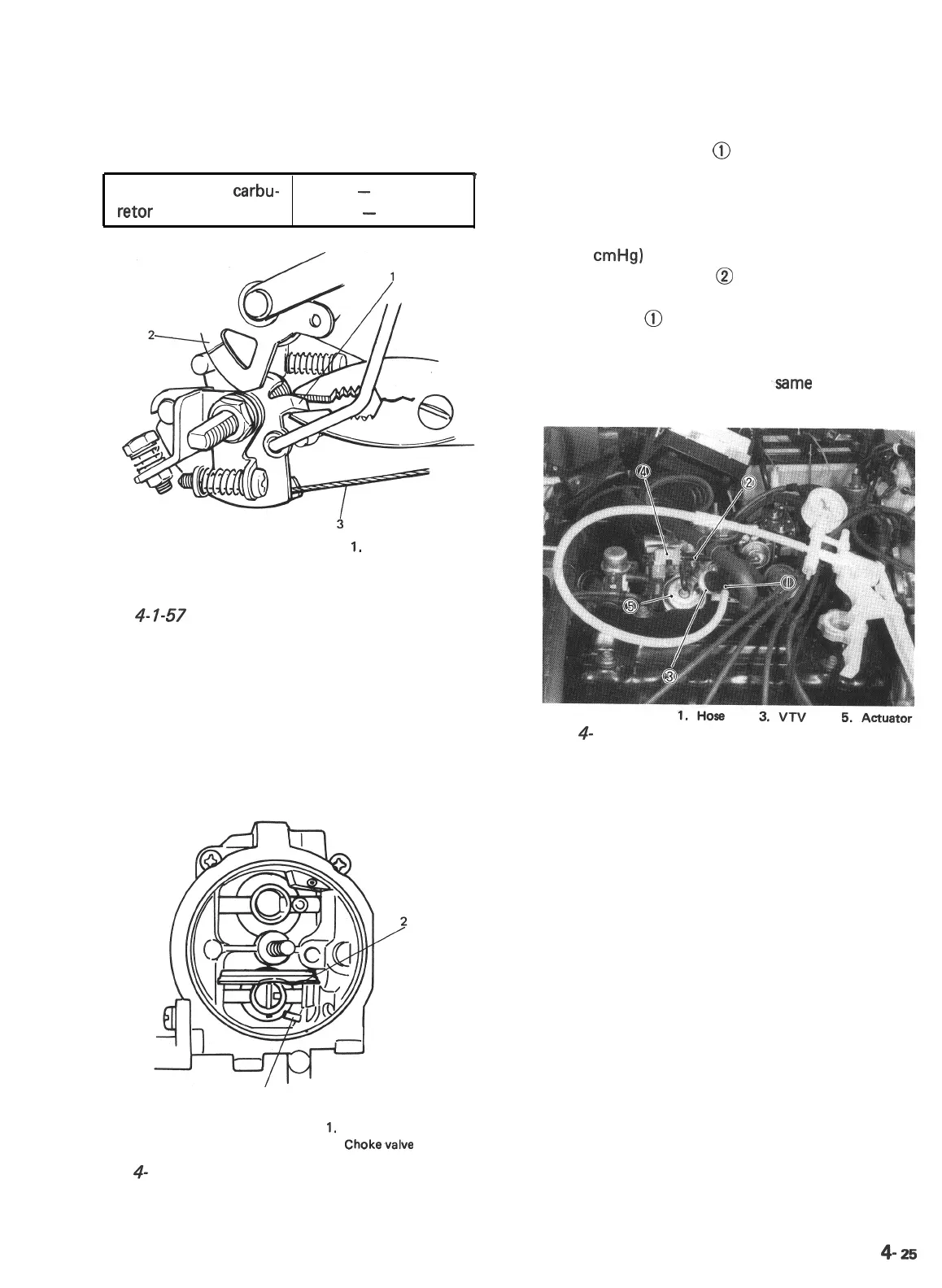

Checking Secondary System

1) Remove air intake case.

2) Disconnect hose

@

from 3 way joint, and

connect vacuum pump gauge.

3) Open primary throttly valve fully.

4) Check if secondary throttle valve opens

smoothly and is held there when vacuum

(10

cmHg)

is applied to actuator.

5) Disconnect hose

@

from 3 way joint and

connect vacuum pump gauge to its hose.

Plug hose

@

with finger.

.

6) Turn ignition switch to “ON” position and

open primary throttle valve fully. 5 or 6

seconds later, make the

.same

check as in

above step 4).

1.

Unloader arm

2. Fast idle cam

3. Accelerator cable

Fig. 4- 7-57 Unloader lever arm

Checking Acceleration Pump

1) Remove air intake case.

2) Make sure that fuel comes out of pump

discharge nozzle when accelerator pedal is

depressed.

Fig.

4-

l-59

2. Hose

4. vsv

If check result in step 4) is not satisfactory,

check VTV, and if that in step 6) is not satis-

factory, check VSV.

If not satisfactory in either step 4) or 6) and both

VTV and VSV are in good condition, replace

actuator.

[VTV (Vacuum Transmitting Valve)]

Remove VTV. Use a vacuum pump gauge for

VTV check. If pointer of vacuum pump gauge

reacts as described below in each condition,

VTV is in good condition.

1

I,

Pump discharge nozzle

2.

Choke,valve

Fig.

4-

1-58 Pump discharge nozzle

With vacuum pump gauge set at Brown side of

VTV, when pump is operated, pointer doesn’t

move (remains at zero position).

4-

25

Loading...

Loading...