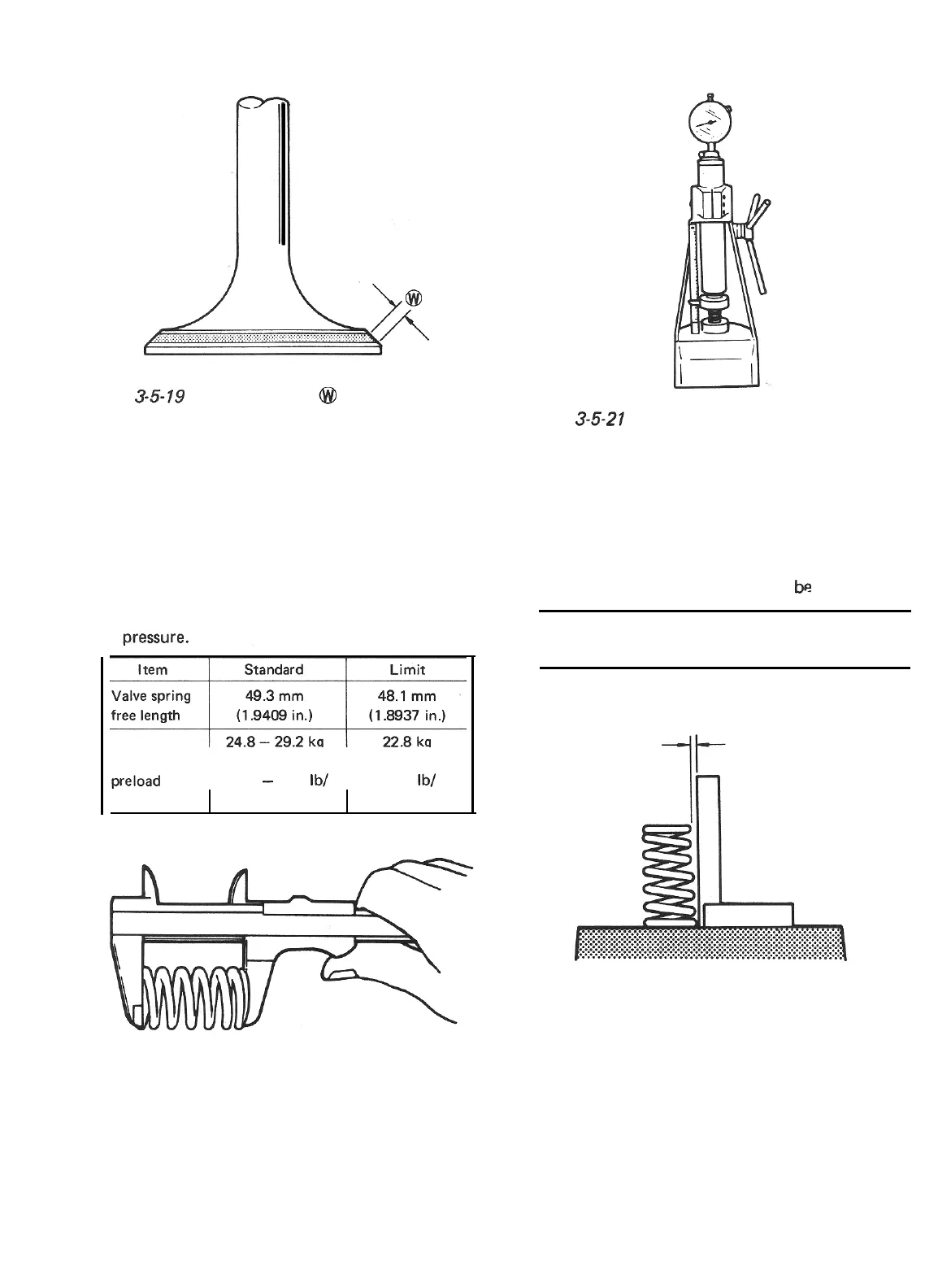

Fig. 3-5-19 Contactpattern

@

uniform in width

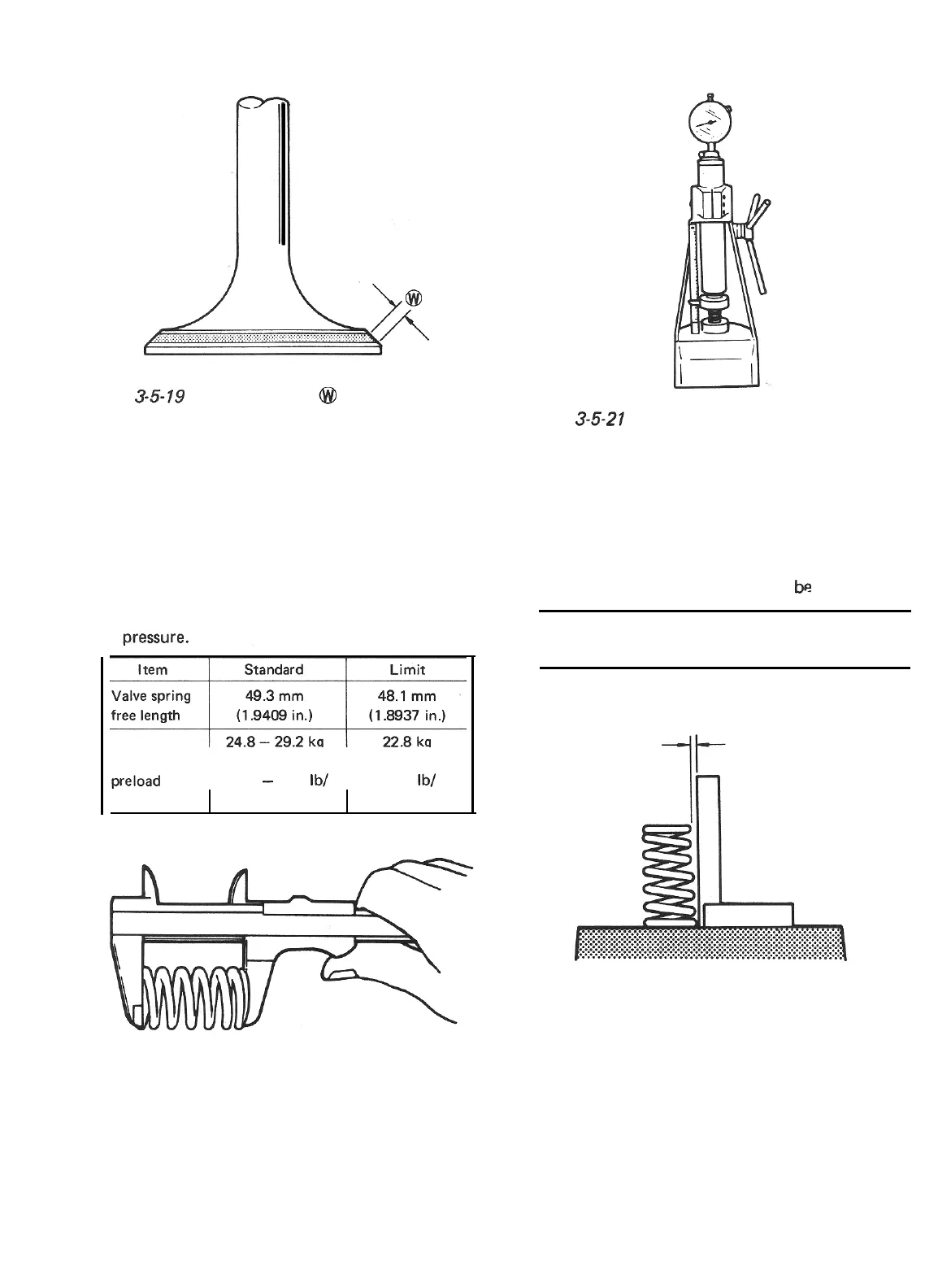

Valve Springs

l Referring to the criterion-data given below,

check to be sure that each spring is in sound

condition, free of any evidence of breakage or

weakening. Remember, weakenedvalve springs

can be the cause of chatter, not to mention

the possibility of reducing power output due

to gas leakage caused by decreased seating

Valve spring

for 41.5 mm

for 41.5 mm

preload

(54.7

-

64.3 lb/

(50.2 lb/

1.63

in.)

1.63 in.)

Fig. 3-5-21 Measuring spring preload

l

Spring squareness:

Use a square and surface plate to check each

spring for squareness in terms of clearance

between the end of valve spring and square.

Valve springs found to exhibit a larger clea-

rance than specified limit must

be

replaced.

Valve springs

squareness limit

2.0 mm (0.079 in.)

Fig. 3-5-22 Measuring spring squareness

Fig. 3-5-20 Measuring free length of spring

3-23

Loading...

Loading...