cl

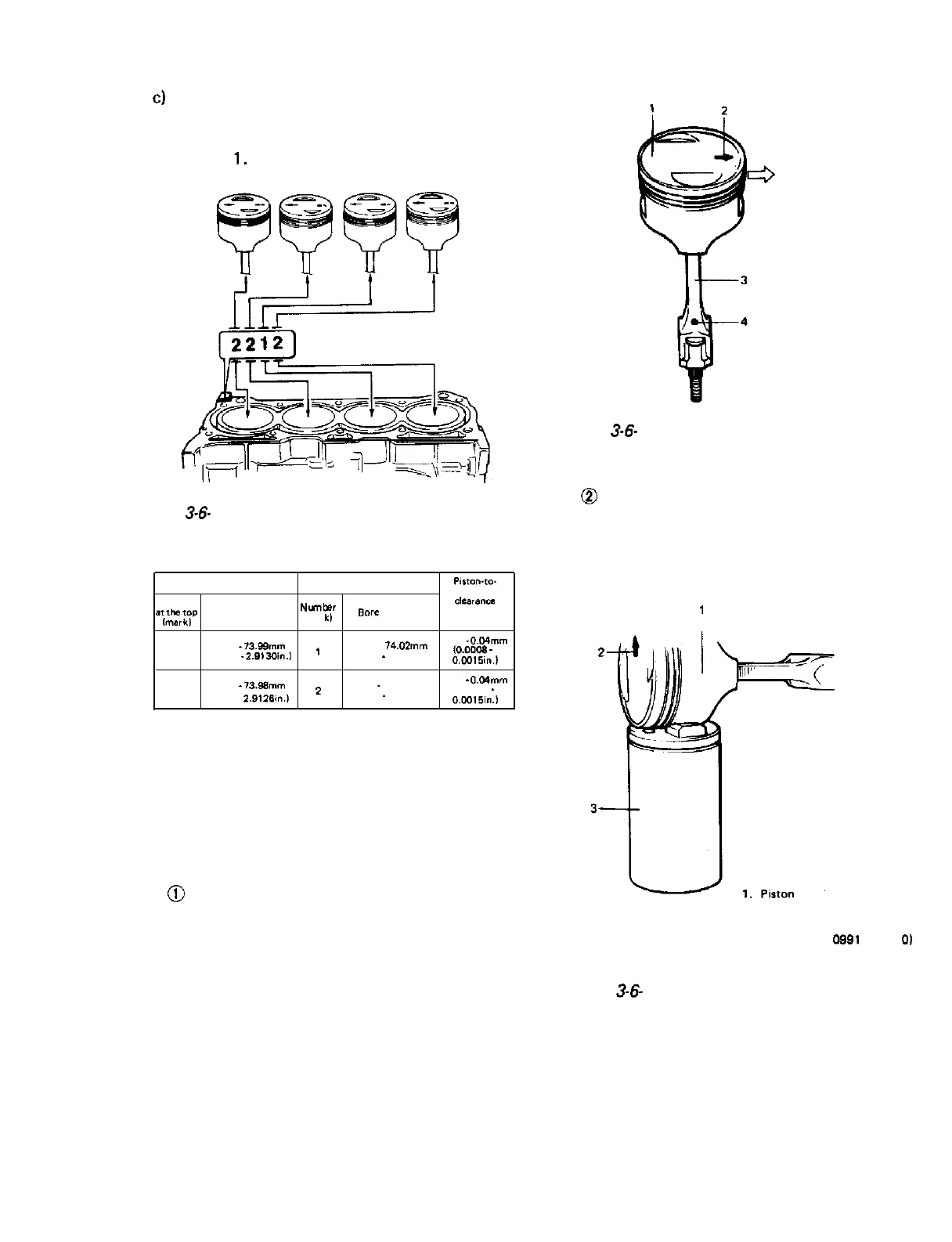

Use a number 2 stamped piston for installa-

tion if cylinder is identified with number 2

and a number 1 piston for cylinder with

number

1.

Fig.

3-6-

11

Piston

Cylinder

Piston-to-

cylinder

Number

a;$;r$p

Outside diameter

NWtlber

ck?arancE

(mar

kb

Bore

diameter

1

73.96

-

73.99mm

’

74.01 74.02mm

0.02

-

0.04mm

(2.9126

-

2.9130in.)

(2.9138

-

2.9142in.l

~0.0009

-

0.0016in.)

2

73.97

-

73.96mm

74.00

-

74.01 mm

0.02

-

0.04mm

2

(2.9134

-

2.9138in.l

(0.0008

-

0.0016in.l

Also, a letter A, 6, C etc., is stamped on piston

head but ordinarily it is not necessary to dis-

criminate each piston by this number.

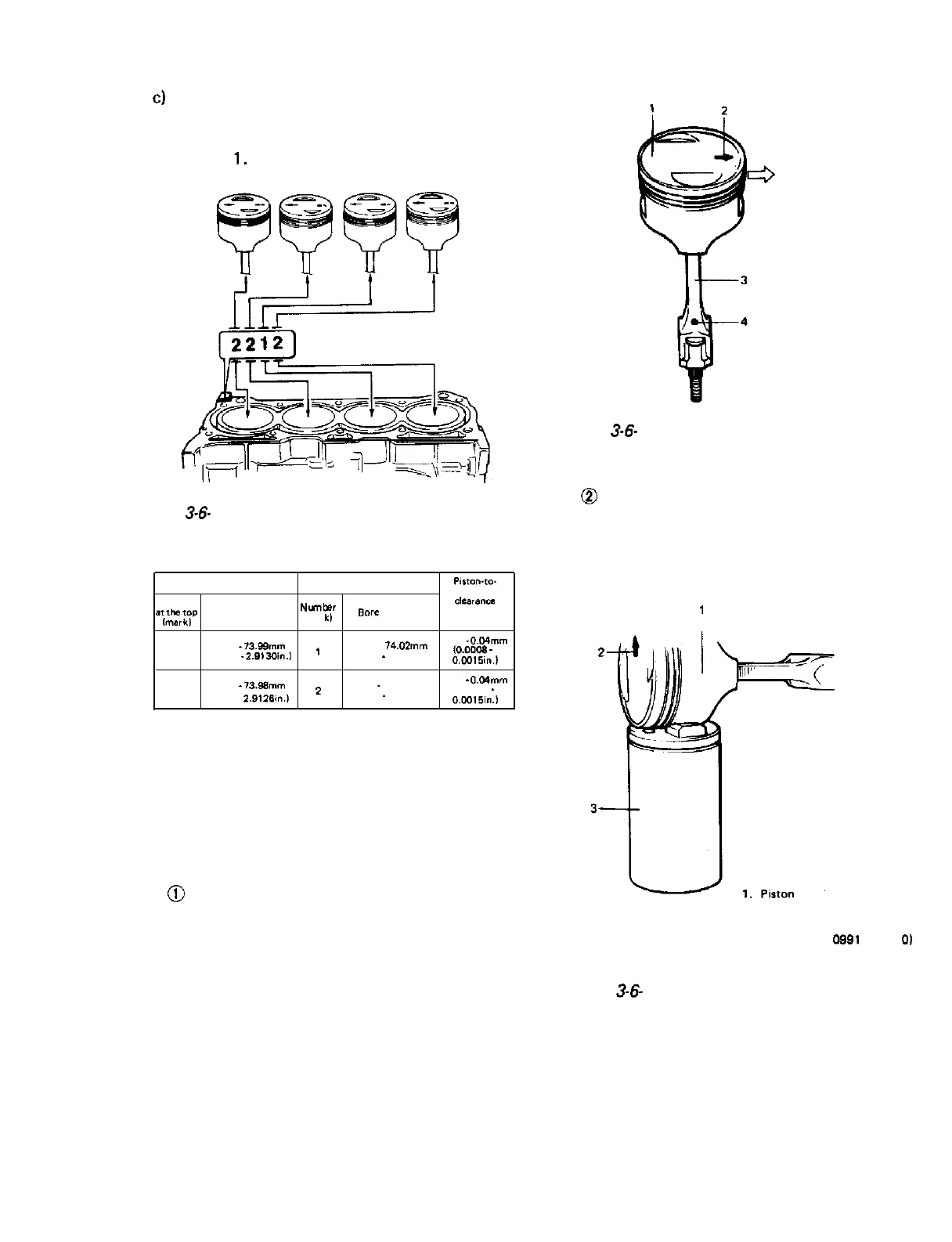

1) Install connecting rod to piston.

@

After applying engine oil to piston pin holes

in piston and connecting rod, fit connecting

rod to piston as prescribed in Fig. 3-6-12.

Crankshaft pulley side

1. Piston

2. Arrow mark

3. Connecting rod

4. Oil hole

(Oil hole should come on

intake side)

Fig.

3-6-

12 Fitting connecting rod to piston

@

Place piston on piston pin remover and

installer (special tool) as indicated in Fig.

3-6-13, and press piston pin into piston and

connecting rod (Fig. 3-6-14).

2. Arrow mark

3. Piston pin remover and installer

(Special tool 0991 O-3821 0)

Fig.

3-6-

13 Fitting piston to special tool

3-39

(2.9122-

Loading...

Loading...