96. STARTING MOTOR INSPECTION

1) Inspect Commutator

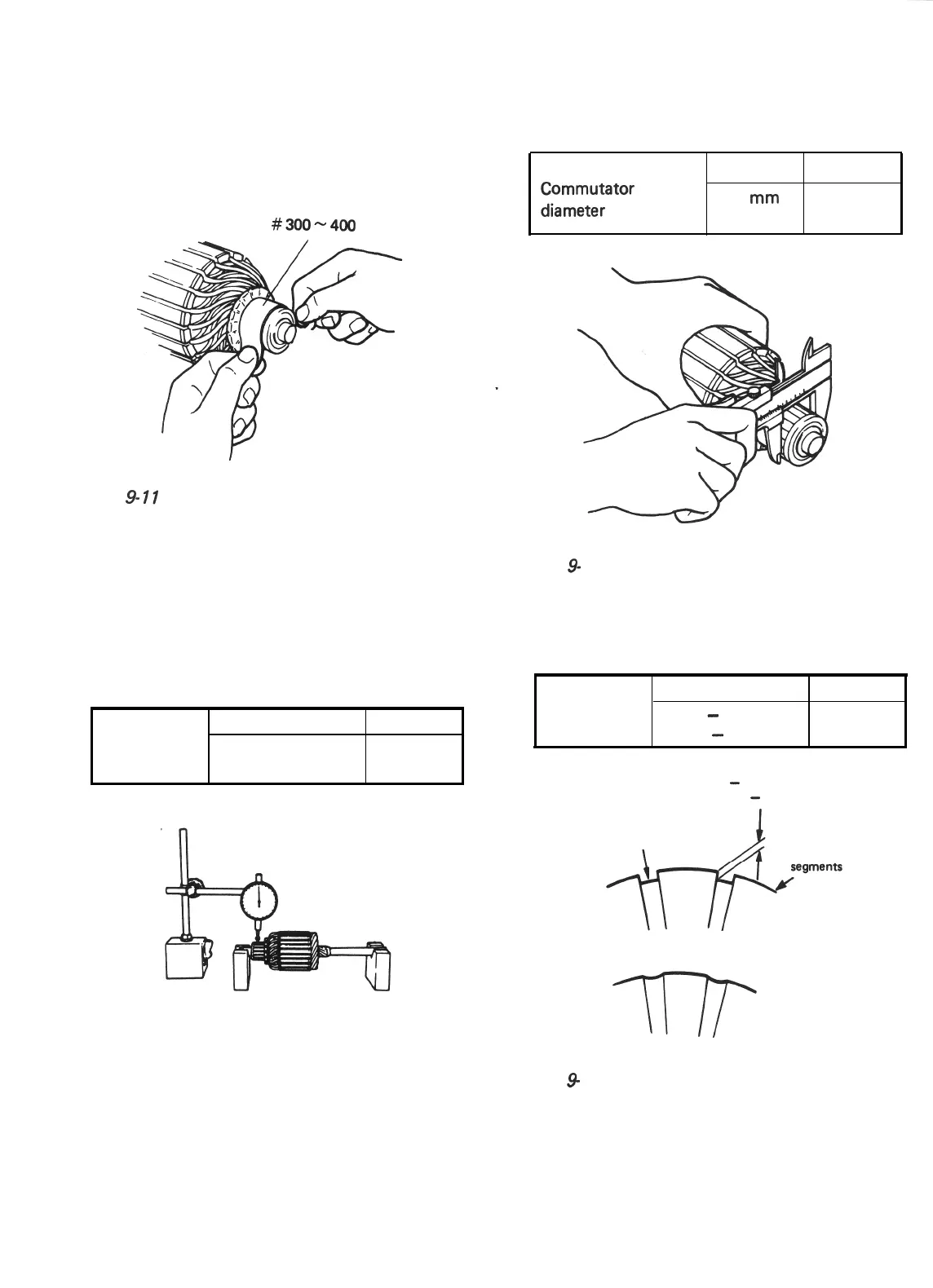

Inspect commutator for dirt or burn. Correct

with sandpaper or lathe, if necessary.

#300-400

.

Fig.

9-

11

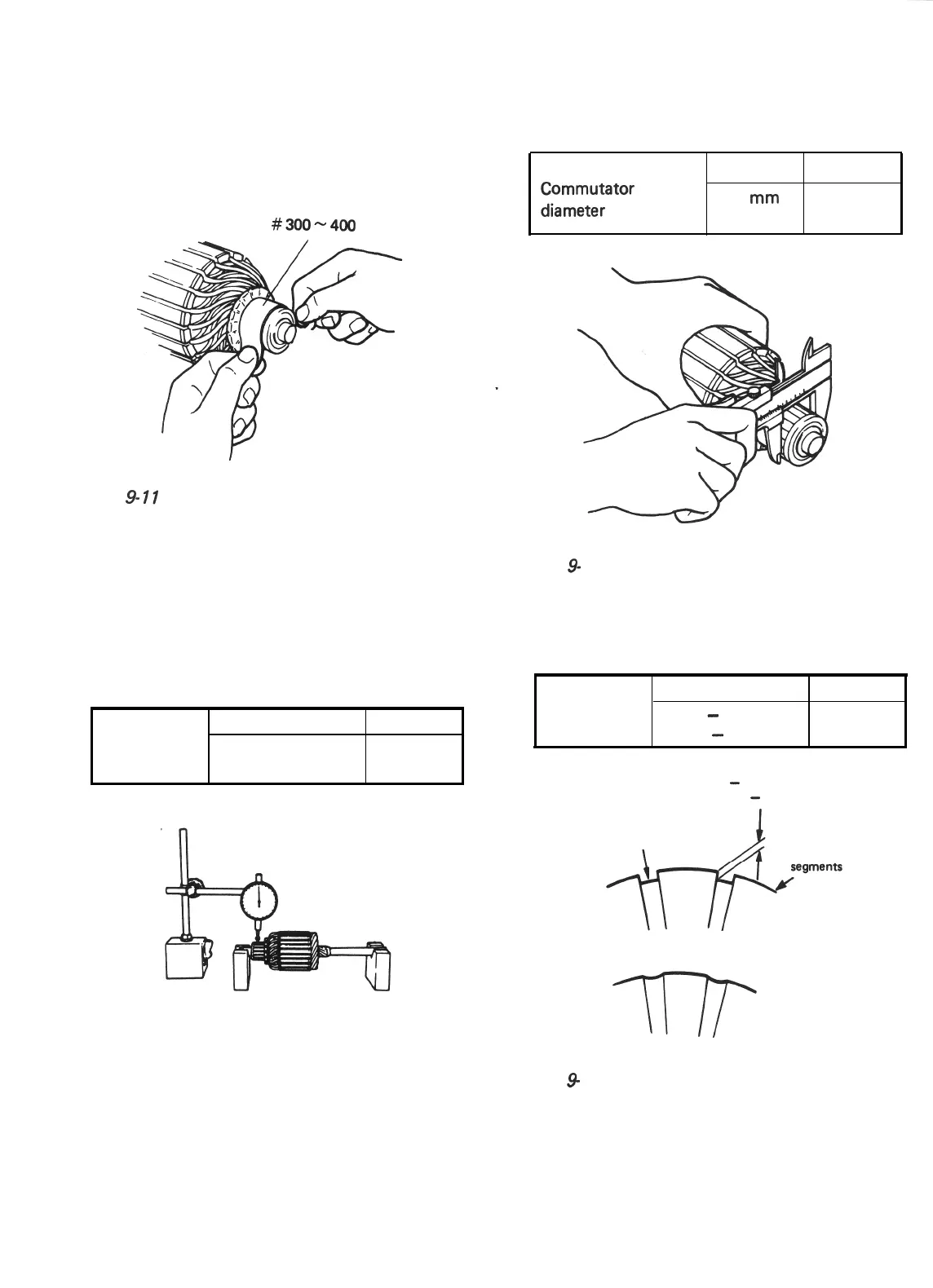

Check commutator for uneven wear. If deflec-

tion of dial gauge pointer exceeds limit, repair

or replace.

NOTE:

Below specification presupposes that armature is

free from bend. Bent shaft must be replaced.

Commutator

out of round

Standard

Limit

0.05 mm (0.0019 in.)

0.4 mm

or less

(0.015 in.)

Inspect commutator for wear. If below limit,

replace armature.

Standard

Limit

Co;ye;tor

outside

32

mm

31 mm

(1.26 in.) (1.22 in.)

Fig.

9-

13

Inspect commutator for mica depth. Correct or

replace if below limit.

Commutator

mica depth

Standard

Limit

0.4

-

0.6 mm

0.2 mm

(0.015

-

0.023 in.) (0.0076 in.)

0.4

-

0.6 mm

(0.015

-

0.023 in.)

Insulator

Commutator

CORRECT

Fig. 912

INCORRECT

Fig.

9

14

9-7

Loading...

Loading...