Remove side gears, differential pinions and

thrust washers.

Fig. 16-17

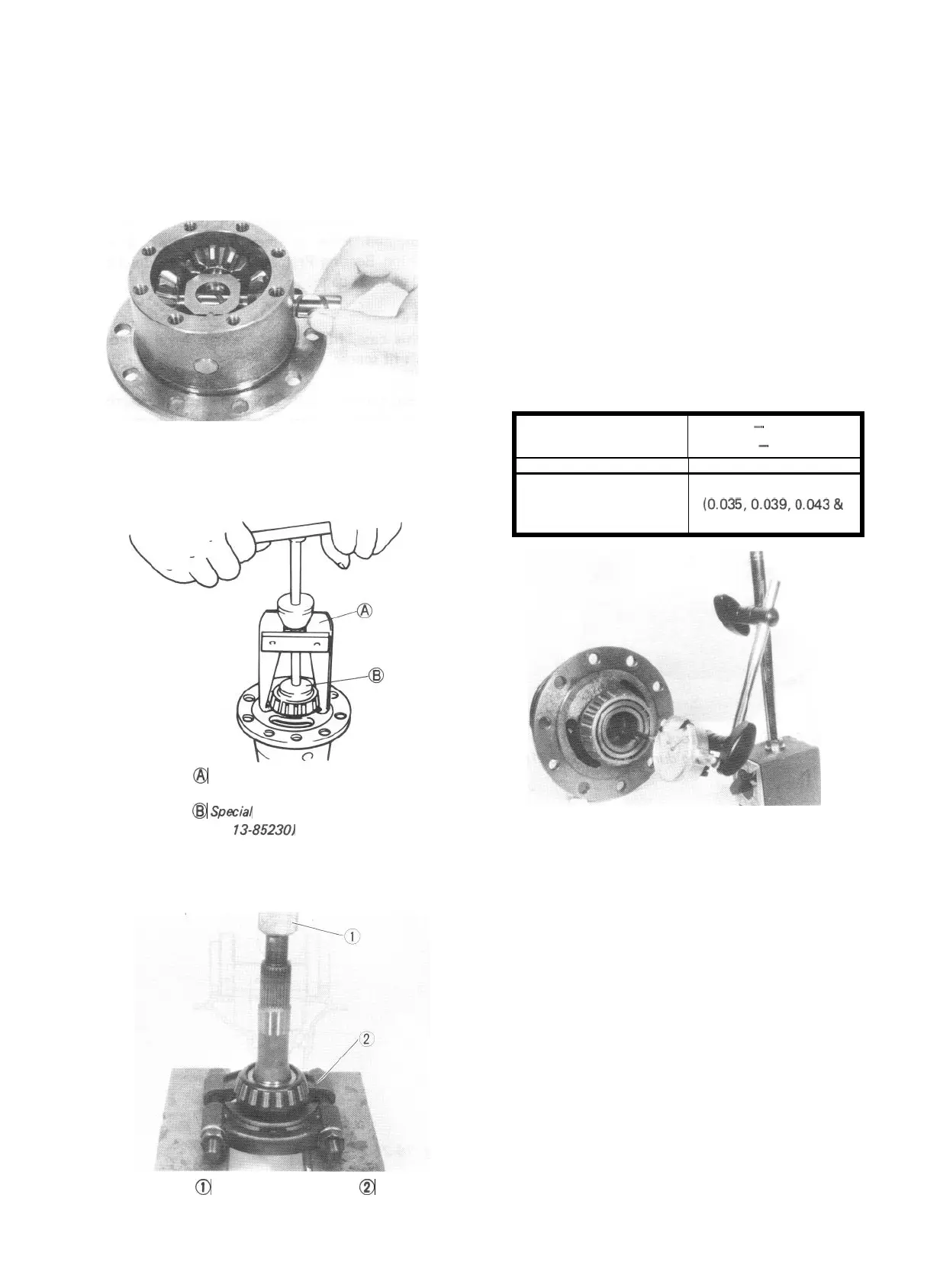

Using special tools indicated below, extract

side bearing from each differential case half.

Fig.16-18

@

Special tool (Bearing puller

09913-60910)

@

SptCal tool (Side bearing removing jig

099 13-85230)

Using puller and hydraulic press, remove inner

race of bevel pinion bearing.

16-4. INSPECTION AND ADJUSTMENT

OF COMPONENTS

Side Gear Thrust Play

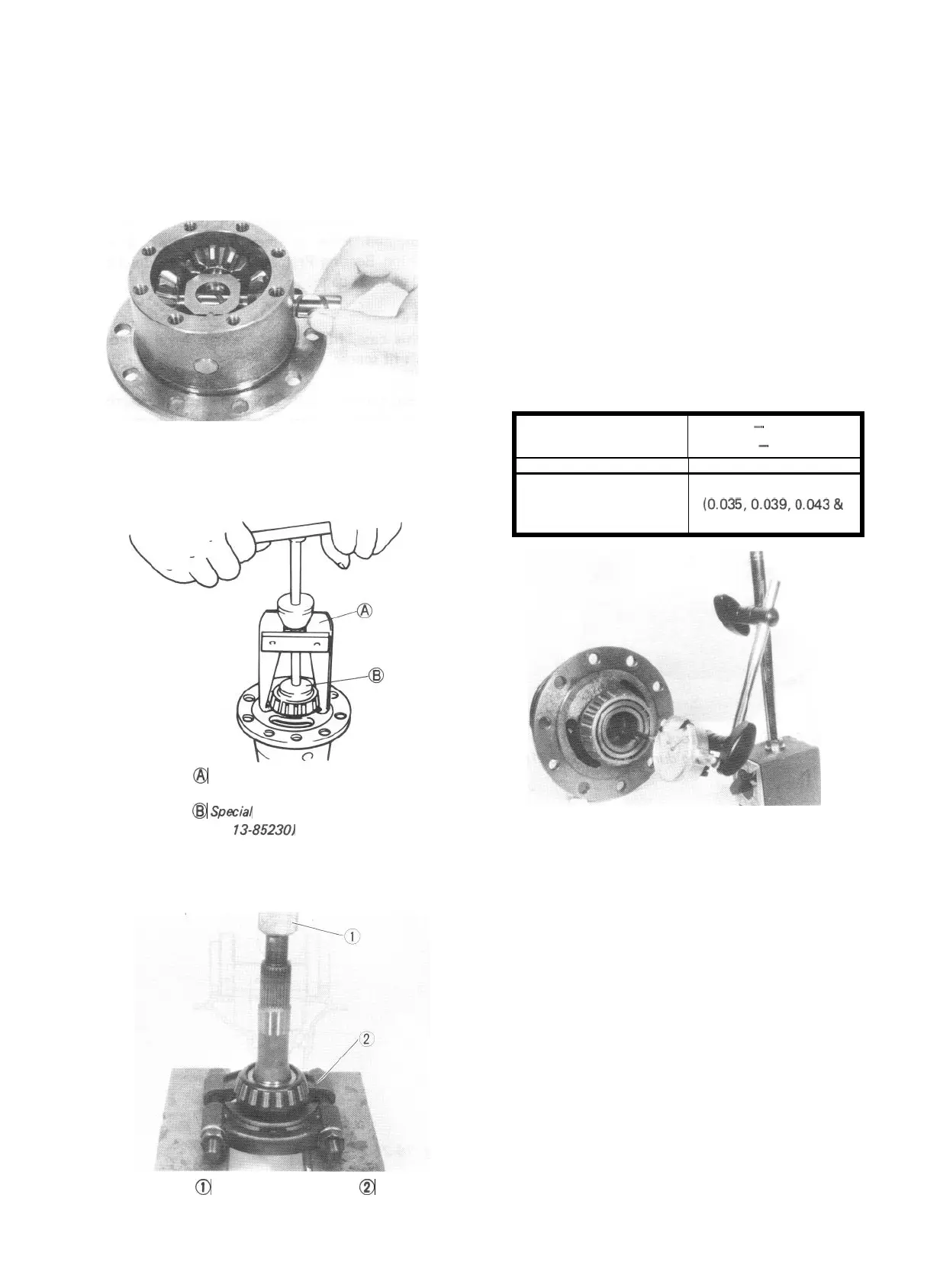

To check thrust play, assemble differential

gearing and case, as shown in Fig. 16-19, fasten-

ing together two case halves by tightening

securing bolts to prescribed torque. By compar-

ing thrust play reading, taken as shown in Fig.

16-19, against thrust play indicated below,

increase or decrease total thickness of thrust

washers, which are located in two places, that

is, on the inner side of each case half.

Side gear thrust play

0.12

-

0.37 mm

specification

(0.005

-

0.014 in)

Available thrust washer

sizes (thickness)

0.9, 1.O, 1.1 & 1.2 mm

(0.035,0.039,0.043

&

0.047 in)

Fig. 16-19

Fig. 16-18-1

0

Hydraulic press

@ Puller

16-7

Loading...

Loading...