16-5. REASSEMBLY

Reverse disassembly procedure for reassembly,

noting the following.

NOTE:

Bevel pinion and bevel gear are supplied as a

set. Even when only bevel pinion or bevel gear

replacement is necessary, be sure to replace

both as a set.

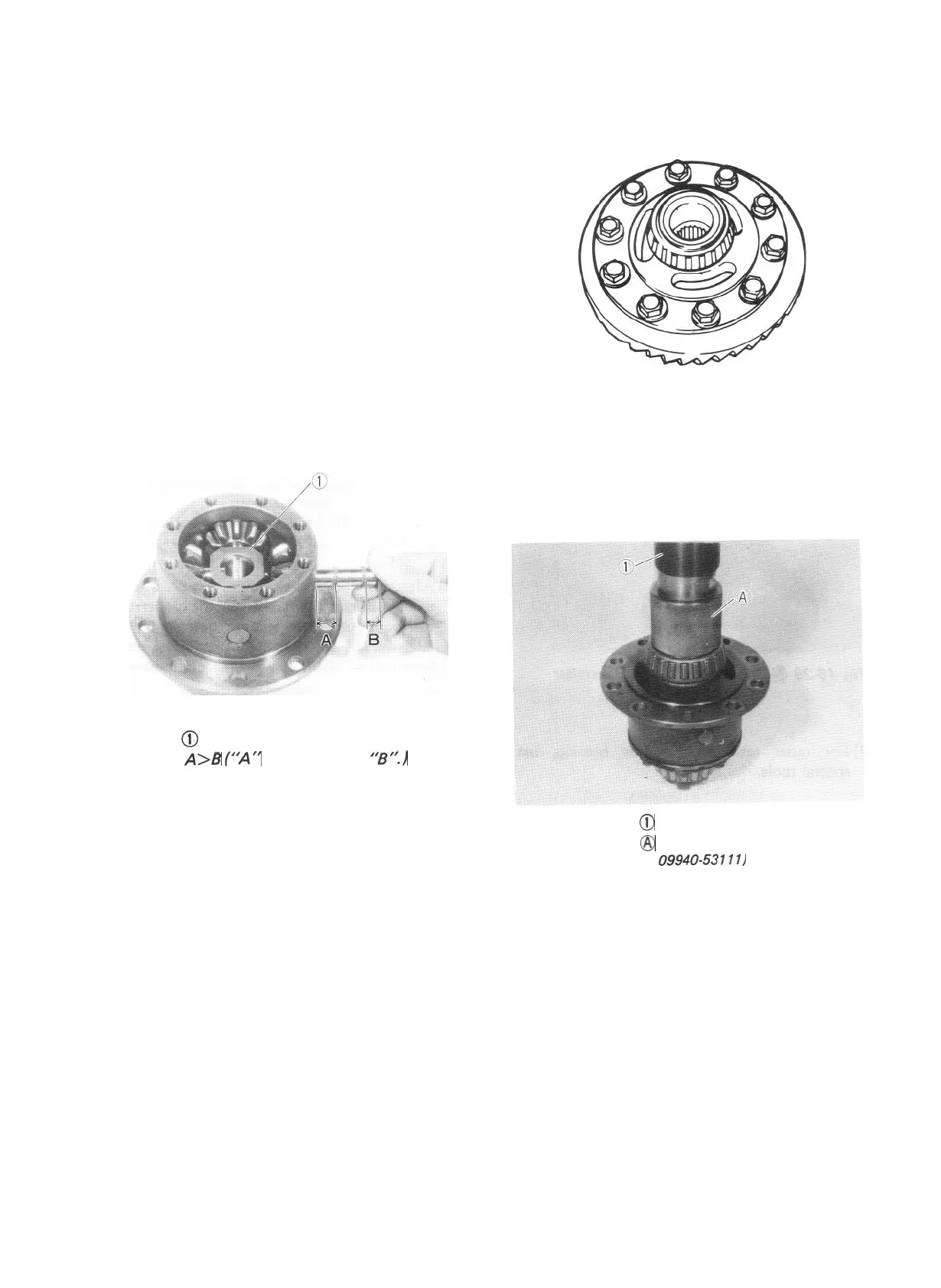

Differential Pinion Shaft (Shorter)

When installing shaft into differential case and

pinion, insert its “A” side into pinion joint.

Fig. 16-26

@

Pinion joint

A>B

(“A”

is longer than

‘/Br’.)

Drive Bevel Gear Bolts

Bolts securing bevel gear to differential case are

subject to shear stress since drive is transmitted

by these bolts from gear to case. For this reason,

they are special bolts made from chrome steel

and must never be replaced by common bolts.

When mounting gear onto case, be sure to apply

THREAD LOCK CEMENT SUPER 1333B

(99000-32020) to these bolts before running

them in.

Fig. 16-26-1

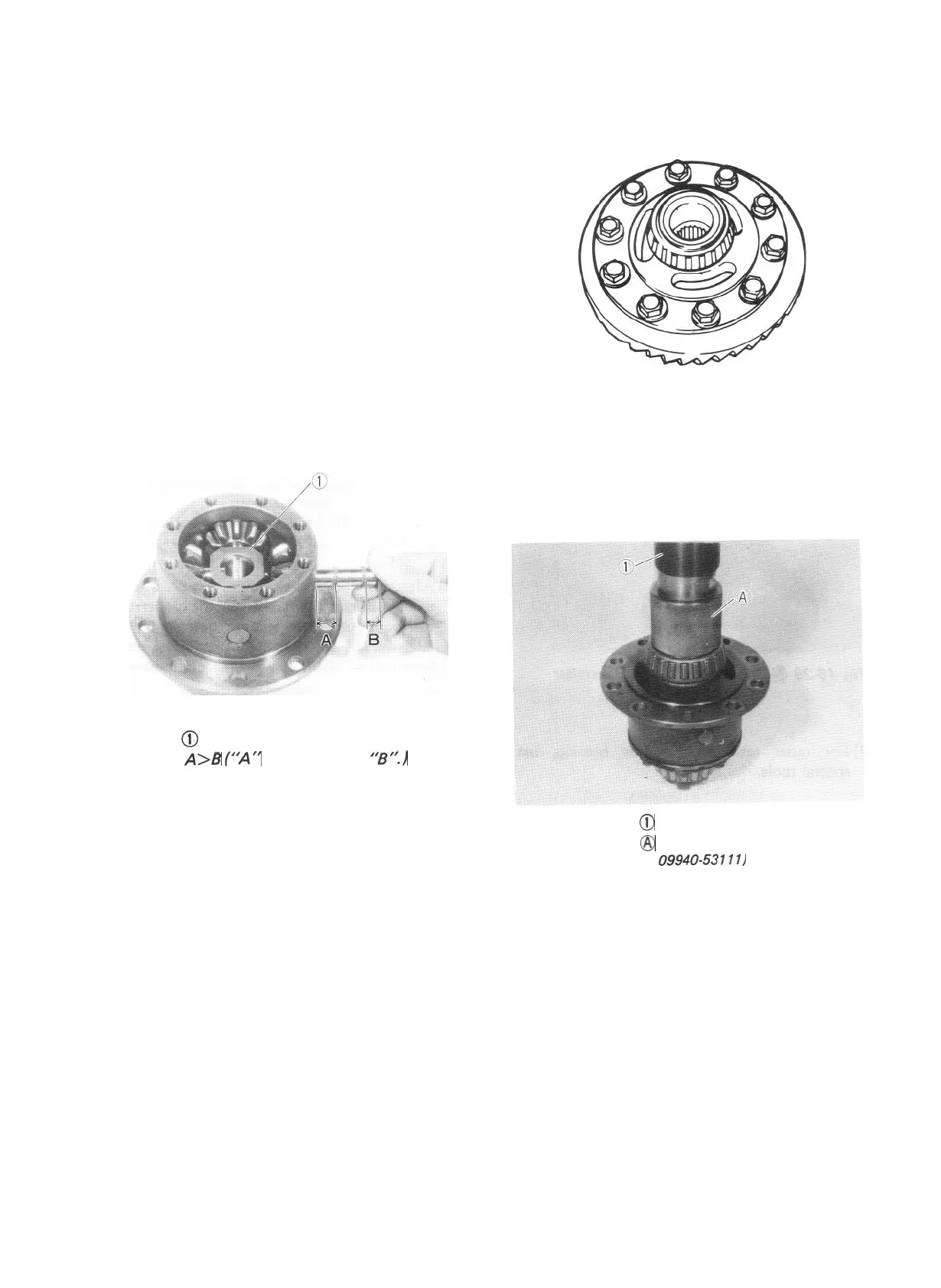

Differential Side Bearings

Press-fit these bearings into differential case by

using special tool. Driving the bearing into case

is not permitted.

Fig. 16-27

@

Press

@

Special tool (Bearing installer

09940-53111)

16-13

Loading...

Loading...