Disassembly

Note:

• All numbers given within brackets in the

procedure below, refer

directly

to

the

numbered items in

the

above diagram.

Make

a note or mark the orientation

of

all parts prior

to removal.

1.

Remove the ball bearing

(1)

and washer (2).

2.

Remove first gear

(3)

and

its needle roller

bearing

(4).

3.

Remove the first gear thrust washer

(5).

4.

Remove fifth gear

(6),

revealing a circlip

(7)

that

secures fourth

and

third gears.

5.

Remove the circlip

(7).

6.

Slide off

the

thrust washer

(8)

from

in

front

of

fourth gear

(9),

then slide off fourth

gear.

7.

Slide off third gear (10), the splined third/fourth

gear

bush

(11)

and

the thrust washer (12).

8.

Remove the circlip

(13)

from

in

front

of

the

splined

dog

ring (14).

9.

Slide off the splined

dog

ring

(14).

10. Remove the circlip

(15)

from

in

front

of

second

gear (17).

11. Slide off the second gear thrust washer (16),

then second gear

(17)

and

its

bush

(18).

12. Working

now

from the other

end

of

the

shaft,

remove

the

large

nut

(20)

Bellville washer

(21)

and flat washer

(22).

13.

Slide off

the

ball bearing

(23),

output gear

(24)

and

spacer (25).

When using a

press,

always wear overalls,

eye

face

and hand protection. Objects such

as

bearings

frequently break-up under load

and

the debris

caused during break-up

may

cause damage

and

injury to unprotected parts

of

the

body.

Transmission

Never wear loose clothing, which could become

trapped

in

the press and cause crushing injury to the

hand, arms or other parts

of

the anatomy.

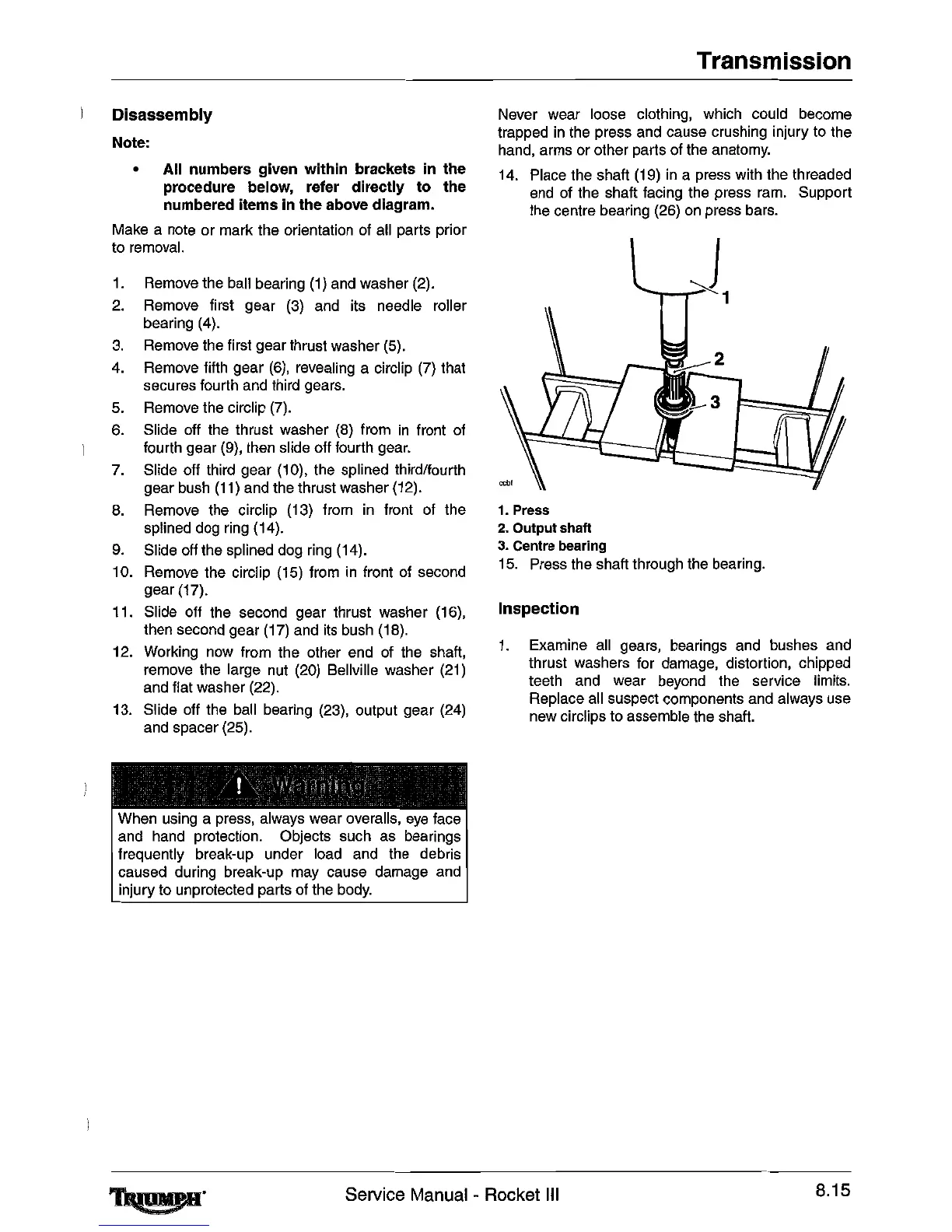

14.

Place the shaft

(19)

in

a press with the threaded

end

of

the shaft facing the press

ram.

Support

the centre bearing

(26)

on

press

bars.

J

-...--...

1

1.

Press

2.

Output shaft

3.

Centre

bearing

15.

Press the shaft through the bearing.

Inspection

1.

Examine

all

gears, bearings

and

bushes and

thrust washers for damage, distortion, chipped

teeth

and

wear

beyond

the

service limits.

Replace all suspect components and always use

new circlips to assemble the shaft.

~.

Service Manual - Rockellll

8.15

Loading...

Loading...