Pistons

Crankshaft

Note:

Disassembly

1.

Remove

the

cylinder head

and

liners (see page

3.5).

•

The rings may be removed using a

proprietary piston ring expander

tool

or,

if

a tool

is

not

available, carefully spread

the

ring opening using

thumb

pressure then

push

up

on the opposite side

of

the ring

to

remove

it

from

the

piston.

The cylinder liners

and

pistons are made

of

aluminium alloy and

can

therefore

be

easily

damaged. Handle the cylinder liner

and

piston

with

care, ensuring the internal bore

of

the liner and

the

piston skirt

are

not

scratched.

Note:

• It

is

not necessary

to

remove the

connecting rods from the crankshaft, but

the

piston

should

be at the

top

of

its

stroke.

2.

Remove

the

gudgeon pin circlip from one side

of

the piston.

1. GUdgeon pin circlip

3.

Remove the gudgeon pin

by

pushing the pin

through the piston and

rod

toward the side from

which

the

circlip

was

removed.

Note:

Piston

Wear

Check

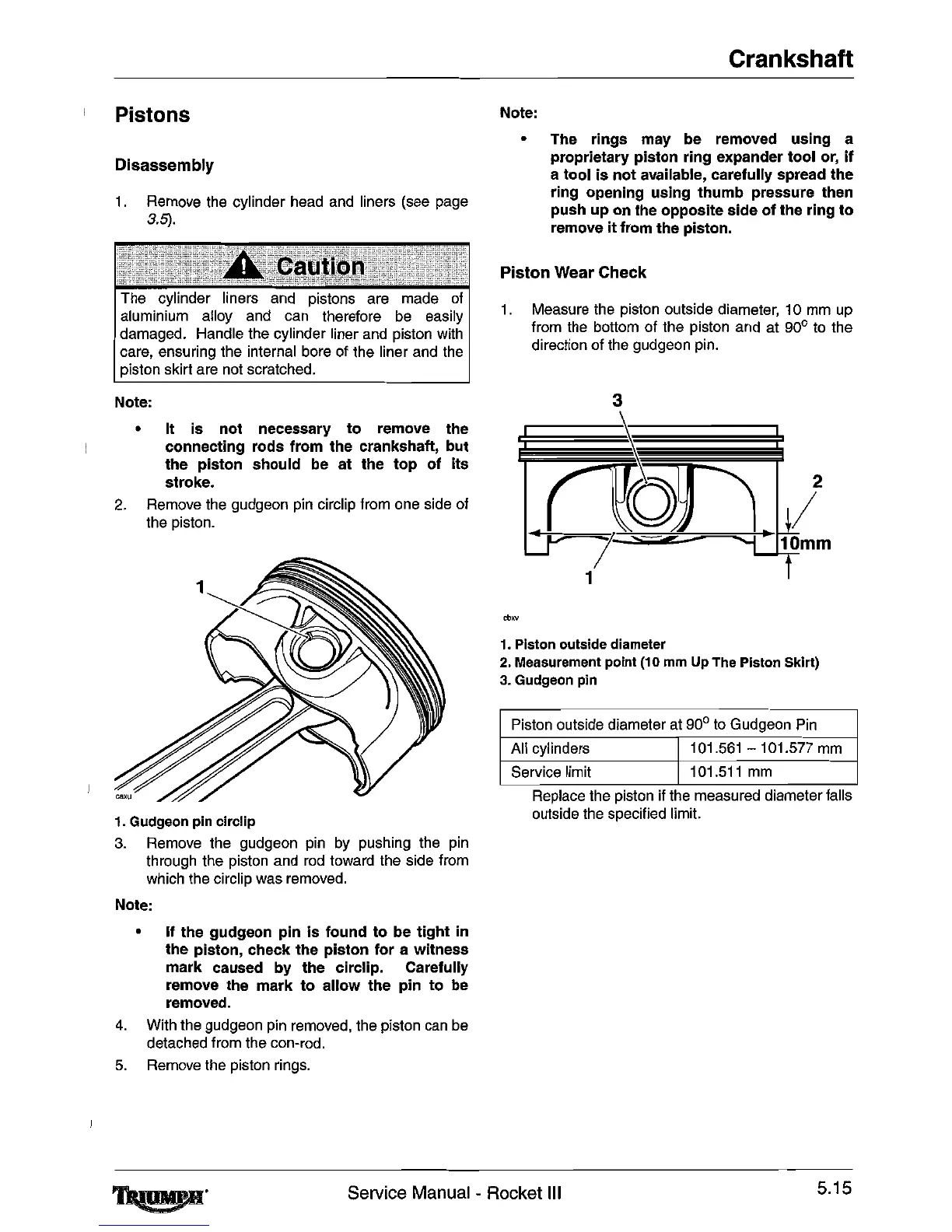

1. Measure

the

piston outside diameter,

10

mm

up

from

the

bottom of the piston

and

at 90°

to

the

direction of

the

gudgeon pin.

3

2

~/

•

7:::::S1iiiiiOi~==:;;;;::j-·

'h

1

iilO

mm

1

1.

Piston outside diameter

2.

Measurement point (10 mm Up The Piston Skirt)

3.

Gudgeon pin

Piston outside diameter at 90°

to

Gudgeon

Pin

All cylinders

101.561

- 101.577

mm

Service limit

101.511

mm

Replace the piston

If

the

measured diameter falls

outside

the

specified limit.

4.

5.

•

If the gudgeon pin

is

found

to

be

tight

in

the

piston, check the piston for a witness

mark caused by

the

circlip. Carefully

remove the mark

to

allow the pin

to

be

removed.

With the gudgeon pin removed, the piston

can

be

detached from the con-rod.

Remove the piston rings.

Service Manual - Rocket III

5.15

Loading...

Loading...