Crankshaft

Connecting Rod Big End Bearing

Selection/Crankpin Wear Check

1.

Measure the bearing and crankpin clearance as

follows.

Note:

• The crankpin clearances are measured

using 'Plastigage' (Triumph part number

3880150·T0301).

Do

not turn the

connecting

rod

and crankshaft during

the

clearance measurement

as

this

will

damage the 'Plastigage'.

2.

Remove the big

end

cap from the journal to

be

checked.

3.

Wipe the exposed areas of the crankpin, and the

bearing

face

inside the

cap.

4.

Apply a thin smear of grease to the journal and a

small quantity of siiicone release agent to the

bearing.

5.

Trim

a length of the Plastigage

to

fit across the

journal. Fit the strip to the journal using the

grease to hold the Plastigage

in

place.

6.

Lubricate the threads

of

the

bolt and under-head

area with undiluted molybdenum disulphide

grease. Refit the bearing and cap and tighten the

big

end bolts as described earlier.

7.

Release the bolts and remove the cap being

measured. Using the gauge provided with the

Plastigage kit, measure the width

of

the

compressed Plastigage.

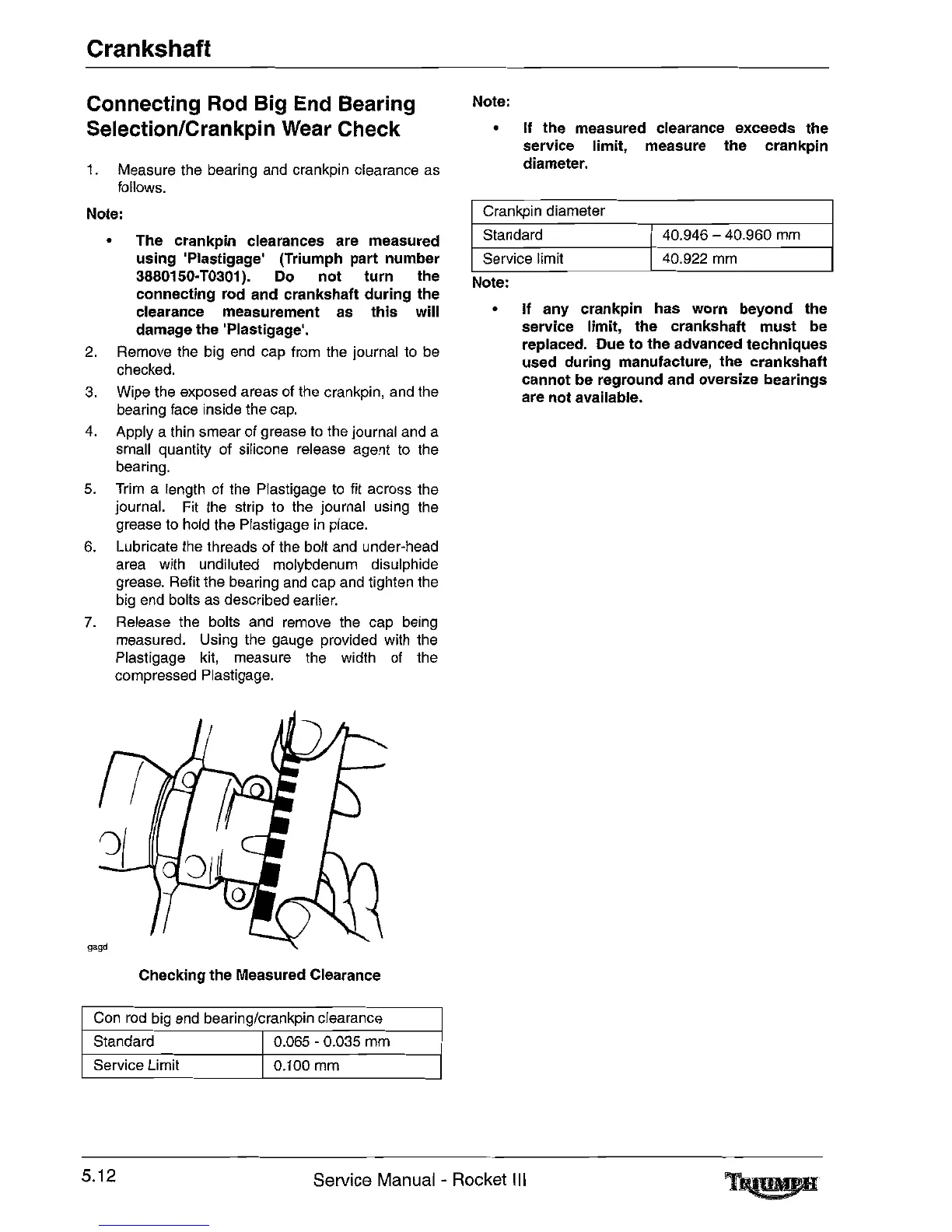

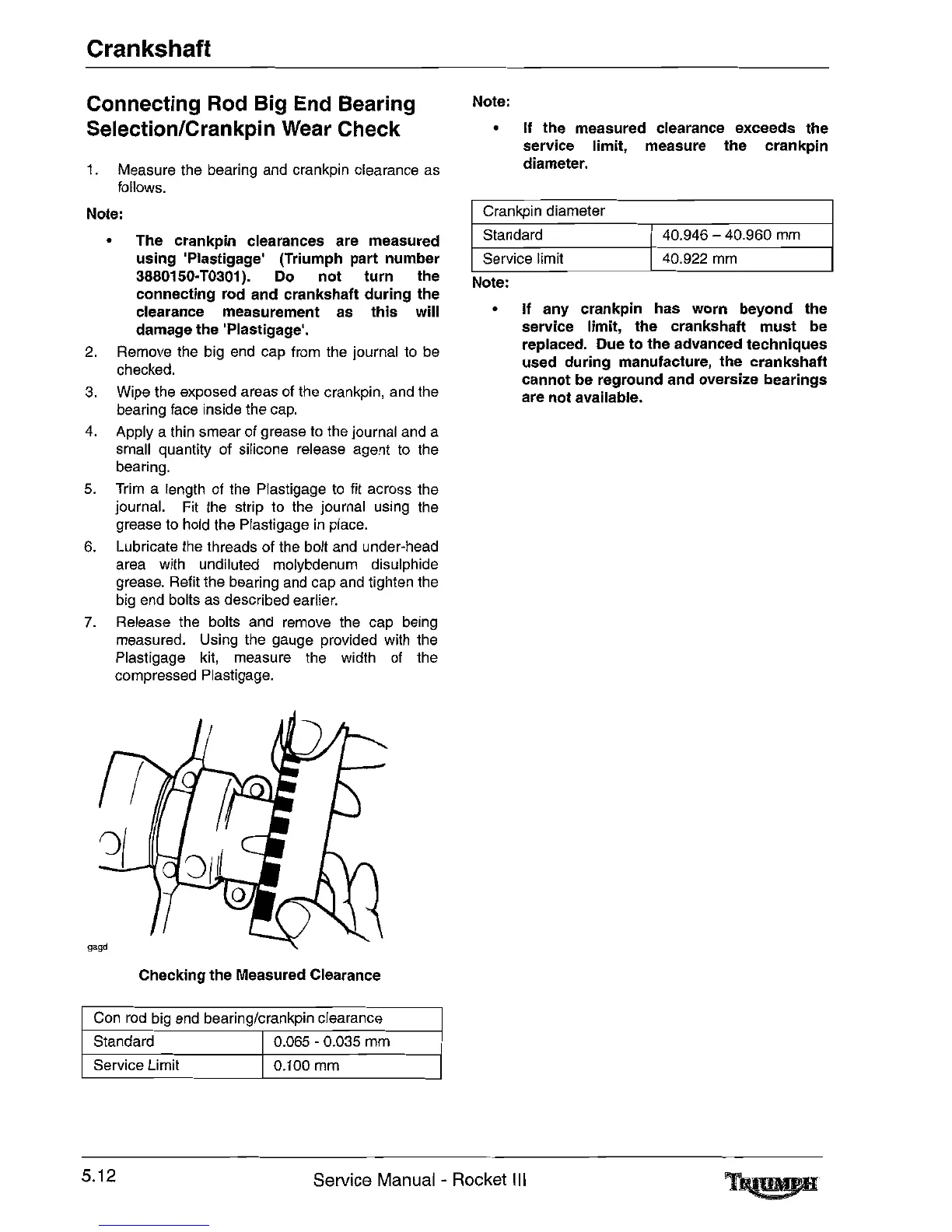

Checking the Measured Clearance

Con

rod

big

end

bearing/crankpin clearance

Standard 0.065 - 0.035

mm

Service Limit 0.100

mm

Note:

•

If

the measured clearance exceeds the

service limit, measure the crankpin

diameter.

Crankpin diameter

Standard 40.946 - 40.960

mm

Service limit 40.922

mm

Note:

•

If

any crankpin has worn beyond the

service limit, the crankshaft must

be

replaced. Due

to

the advanced techniques

used during manufacture, the crankshaft

cannot

be

reground and oversize bearings

are not available.

5.12

Service Manual - Rocket III

Loading...

Loading...