Crankshaft

Piston Rings/Ring Grooves

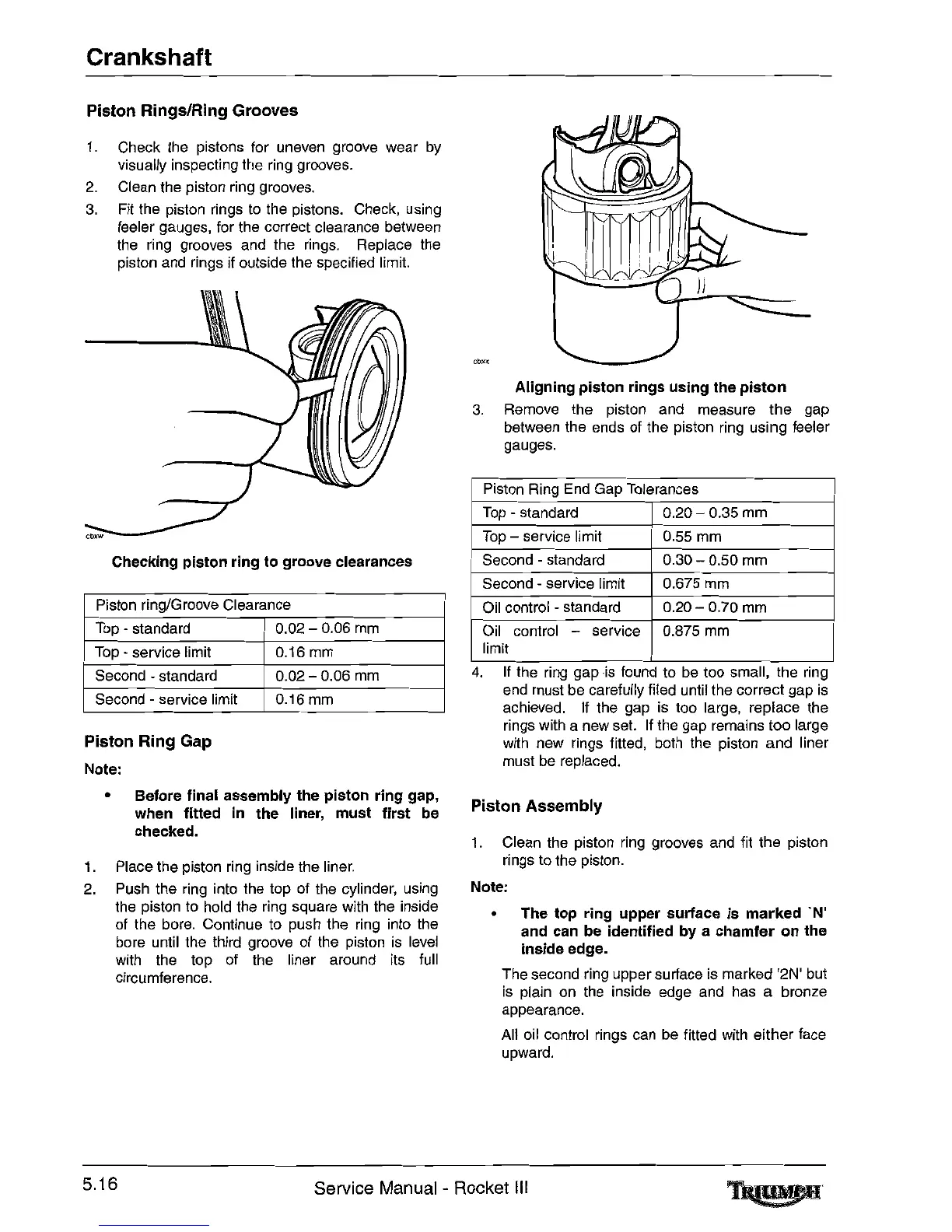

1. Check the pistons for uneven groove wear by

visually inspecting the ring grooves.

2.

Clean the piston ring grooves.

3. Fit the piston rings to the pistons. Check, using

feeler gauges, for the correct clearance between

the ring grooves and the rings. Replace the

piston and rings if outside the specified limit.

Checking piston ring to groove clearances

Piston ring/Groove Clearance

Top - standard

0.02 -

0.06

mm

Top - service limit

0.16 mm

Second - standard

0.02 -

0.06

mm

Second - service limit

0.16 mm

Piston Ring Gap

Note:

• Before final assembly the piston ring gap,

when fitted

in

the liner, must first be

checked.

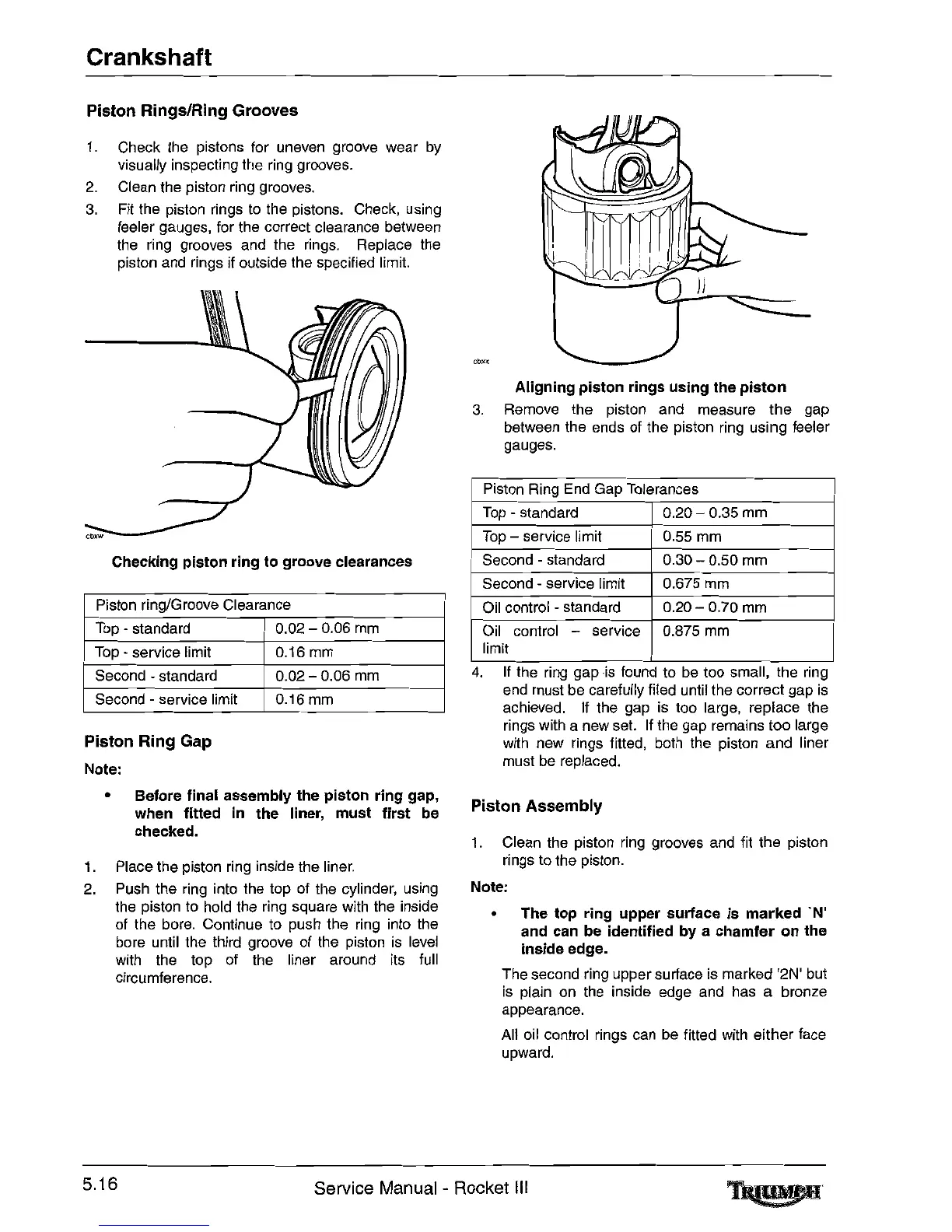

1. Place the piston ring inside the liner.

2. Push the ring into the top of the cylinder, using

the piston to hold the ring square with the inside

of the bore. Continue to push the ring into the

bore until the third groove of the piston

is

level

with the top of the liner around its full

circumference.

",,,

Aligning piston rings using the piston

3.

Remove the piston and measure

the

gap

between the ends of the piston ring using feeler

gauges.

Piston Ring End Gap Tolerances

Top

- standard

0.20 - 0.35 mm

Top

- service limit 0.55 mm

Second - standard

0.30 -

0.50

mm

Second - service limit

0.675 mm

Oil control - standard

0.20 - 0.70 mm

Oil control

- service 0.875 mm

limit

4.

If

the nng gap

IS

found to be too small, the nng

end must be carefully filed until the correct gap

is

aChieved. If the gap is too large, replace the

rings with a new set. If the gap remains

too

large

with new rings fitled, both the piston and liner

must be replaced.

Piston Assembly

1.

Clean the piston ring grooves and fit

the

piston

rings to the piston.

Note:

•

The

top ring upper surface is marked .N'

and

can

be identified

by

a chamfer

on

the

inside edge.

The second ring upper surface is marked '2N' but

is

plain on the inside edge and has a bronze

appearance.

All oil control rings can be fitted with either face

upward.

5.16

Service Manual - Rocket

III

Loading...

Loading...