Cylinder Head

Inspection

1.

Thoroughly clean the surface of the cylinder

head and check for damage and/or pitting of the

combustion chambers.

2.

Using a straight edge

and

feeler gauges, check

the cylinder head gasket face for warp, which

could lead to gasket failure. Replace the cylinder

head

if warped beyond the flatness limit.

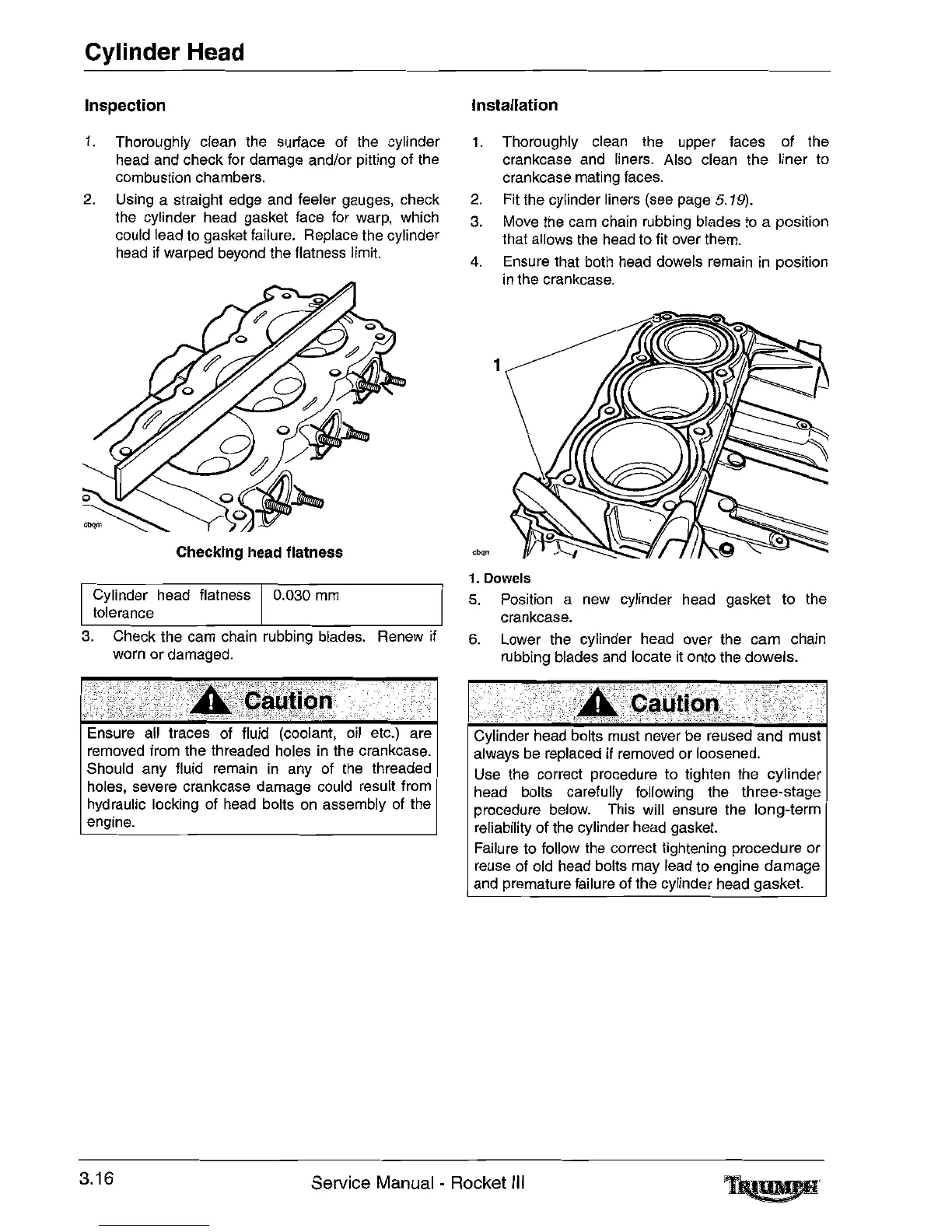

Checking head flatness

Cylinder head flatness 0.030

mm

tolerance

3.

Check the cam chain rubbing blades. Renew if

worn or damaged.

Ensure all traces of fluid (coolant,

oil

etc.) are

removed from the threaded holes

in

the crankcase.

Should any fluid remain

in

any of the threaded

holes, severe crankcase damage could result from

hydraulic locking of head bolts

on

assembly

of

the

engine.

Installation

1.

Thoroughly clean the upper faces of the

crankcase

and

liners. Also clean the liner to

crankcase mating faces.

2.

Fit the cylinder liners (see page 5.19).

3.

Move

the

cam

chain rubbing blades

to

a position

that allows the head to fit over them.

4.

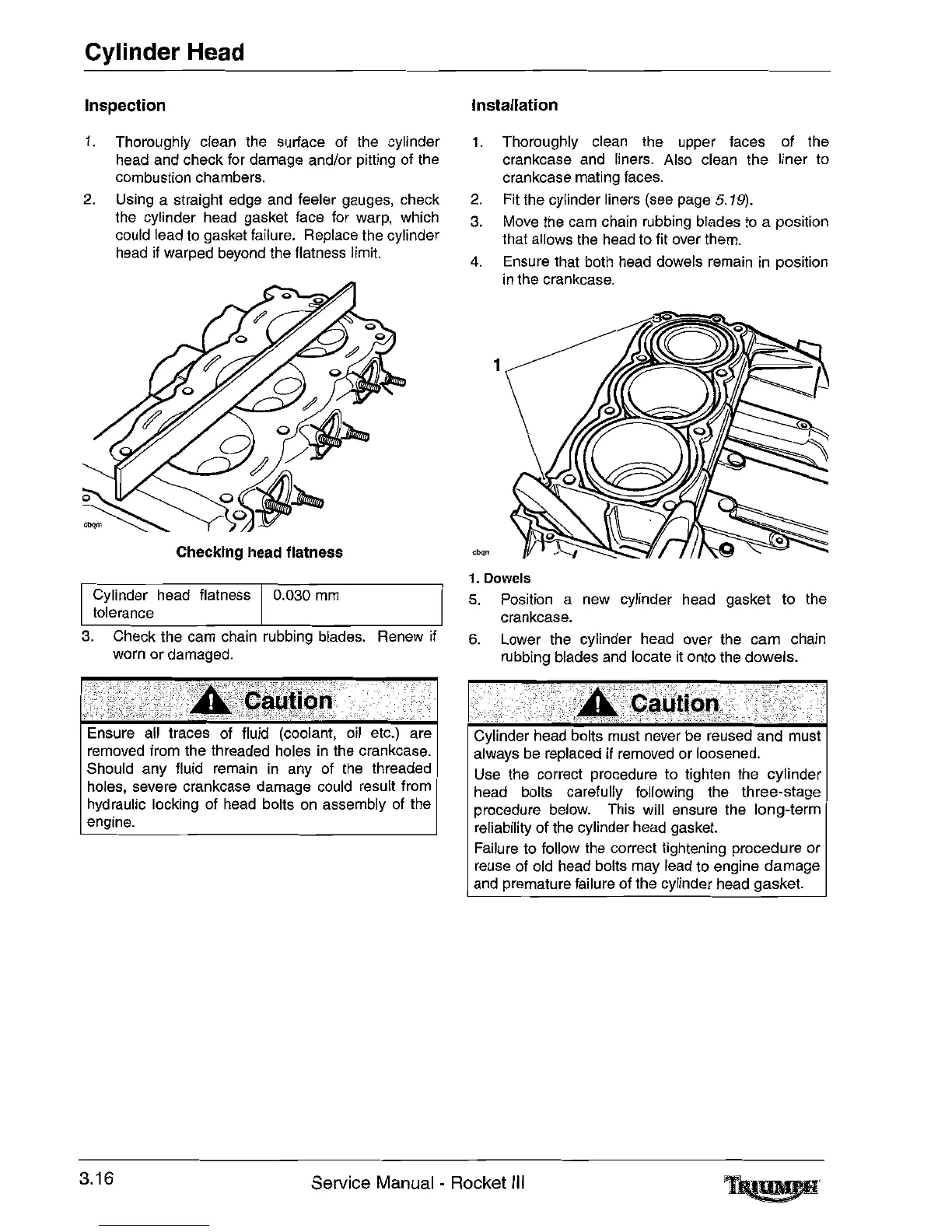

Ensure that both head dowels remain

in

position

in

the crankcase.

1

.",,"

1.

Dowels

5.

Position a new cylinder head gasket to the

crankcase.

6.

Lower the cylinder head over the cam chain

rubbing blades

and

locate it onto the dowels.

Cylinder head bolts must never

be

reused and must

always

be

replaced if removed or loosened.

Use

the

correct procedure to tighten the cylinder

head bolts carefully following the three-stage

procedure

below.

This will ensure the long-term

reliability of the cylinder head gasket.

Failure to follow the correct tightening procedure or

reuse of old

head

bolts may lead to engine damage

and premature failure of the cylinder head gasket.

3.16

Service Manual - Rocket

III

Loading...

Loading...