Crankshaft

Crankcases

The following procedures often require lifting

of

heavy components.

To

avoid

injury, always lift heavy

components

with

a hoist or block and tackle

and

never attempt

to

manually lift items that are too

heavy.

Injury

may

result from failure to

use

the

correct lifting equipment.

The upper

and

lower crankcases are machined

as

a

matched

set

and

must never

be

assembled to non-

matching halves. Doing

so

will cause seizure of the

engine.

Note:

• The crankcase halves may be separated

with

the

cylinder head fitted.

Removal

1.

Remove

the

engine from the frame (see page

10.2).

2.

Remove

the

clutch

(see

page

4.7).

3.

Remove the starter motor

(see

page

18.18)

.

4.

Remove

the

alternator (see page 18.15).

5.

Remove the oil pump drive and pressure

oil

pump (see page 9.11).

6.

Remove the torsional damper shaft (see page

8.11).

7.

Remove the sump (see

page

9.9).

8.

Remove

the

cam

chain (see page 3.6).

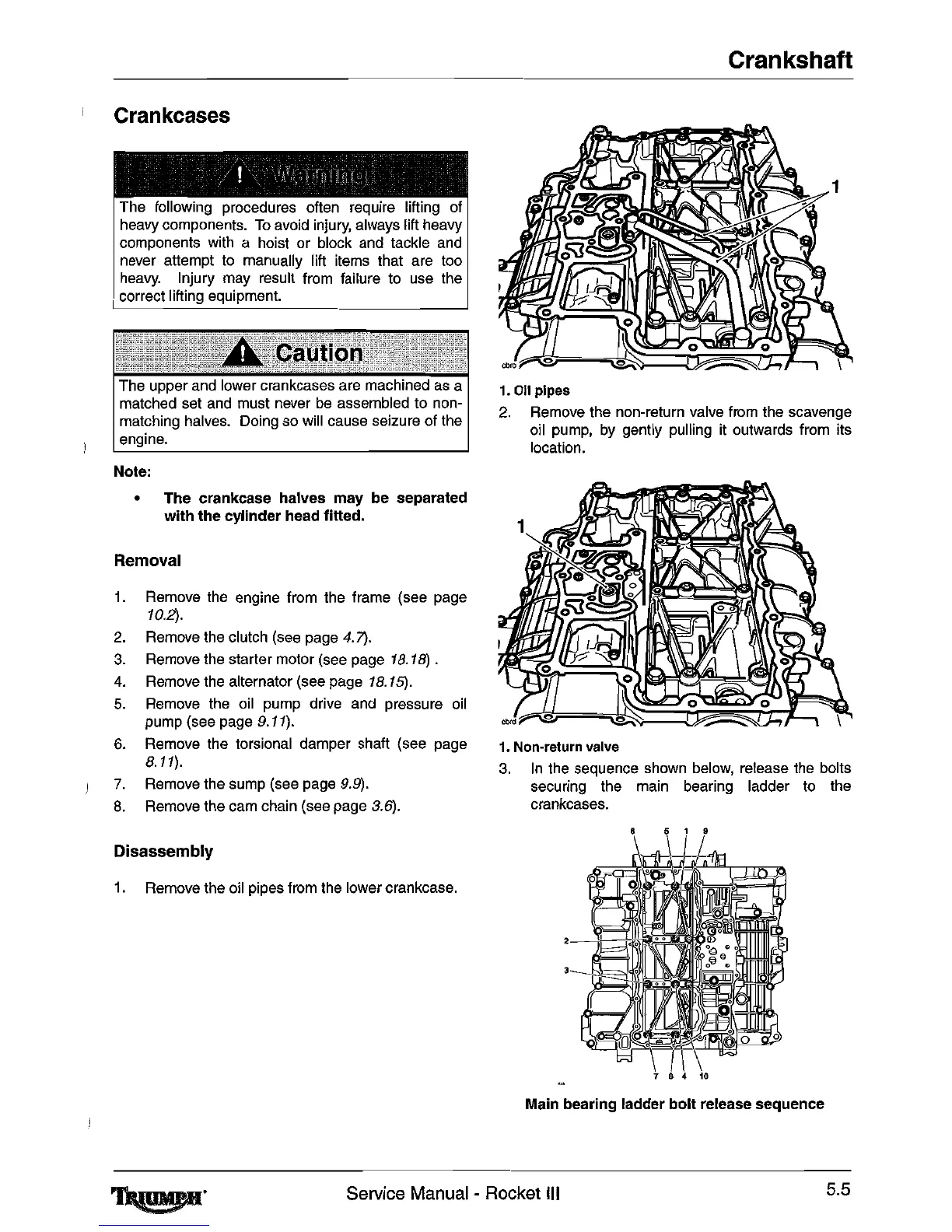

1.011

pipes

2.

Remove the non-return valve from the scavenge

oil

pump,

by

gently

pUlling

it

outwards from its

location.

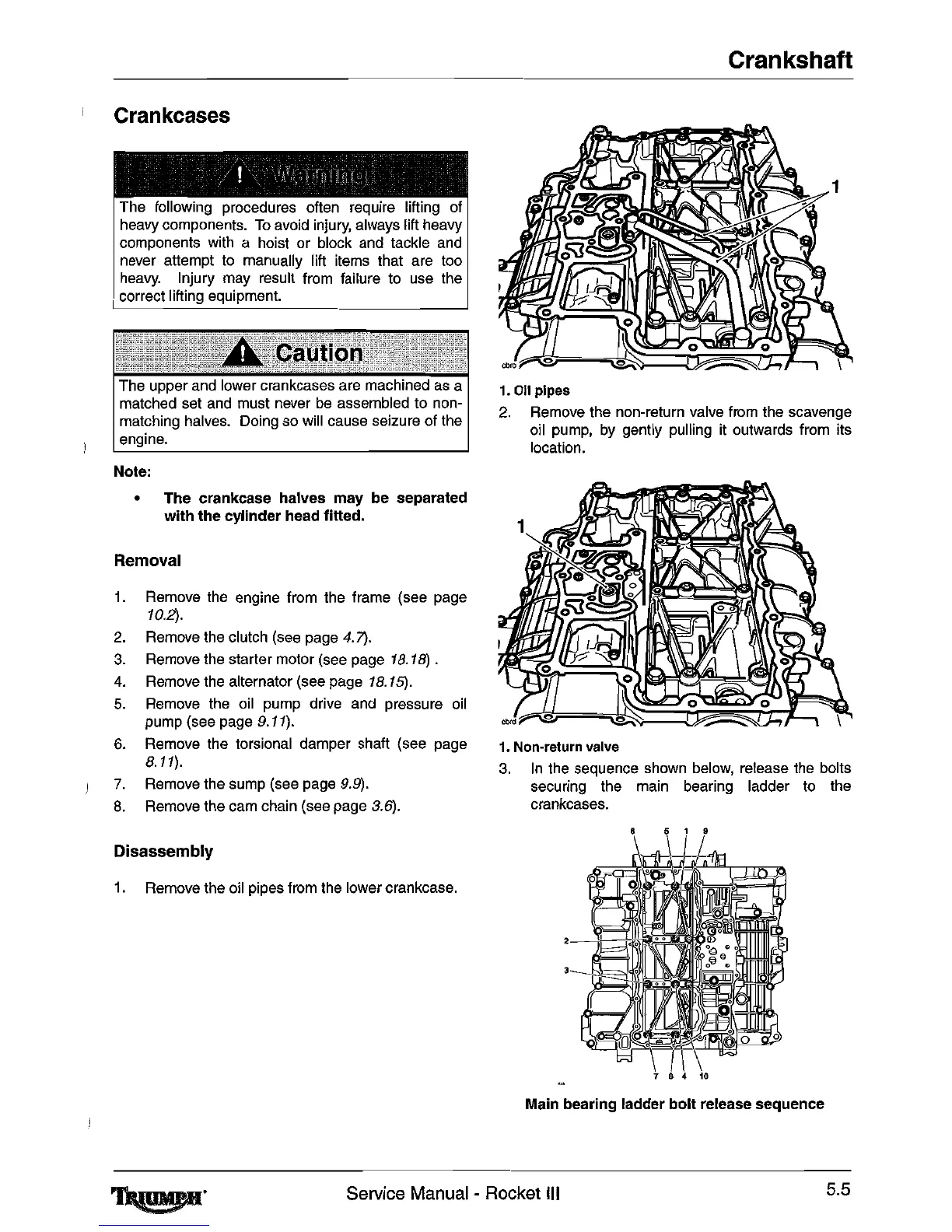

1.

Non-return

valve

3.

In

the

sequence

shown

below,

release

the

bolts

securing the main bearing ladder

to

the

crankcases.

6 5 1 9

Disassembly

1.

Remove the oil pipes from

the

lower crankcase.

2

Main bearing ladder

bolt

release sequence

~.

Service Manual - Rocket III

5.5

Loading...

Loading...