Cylinder Head

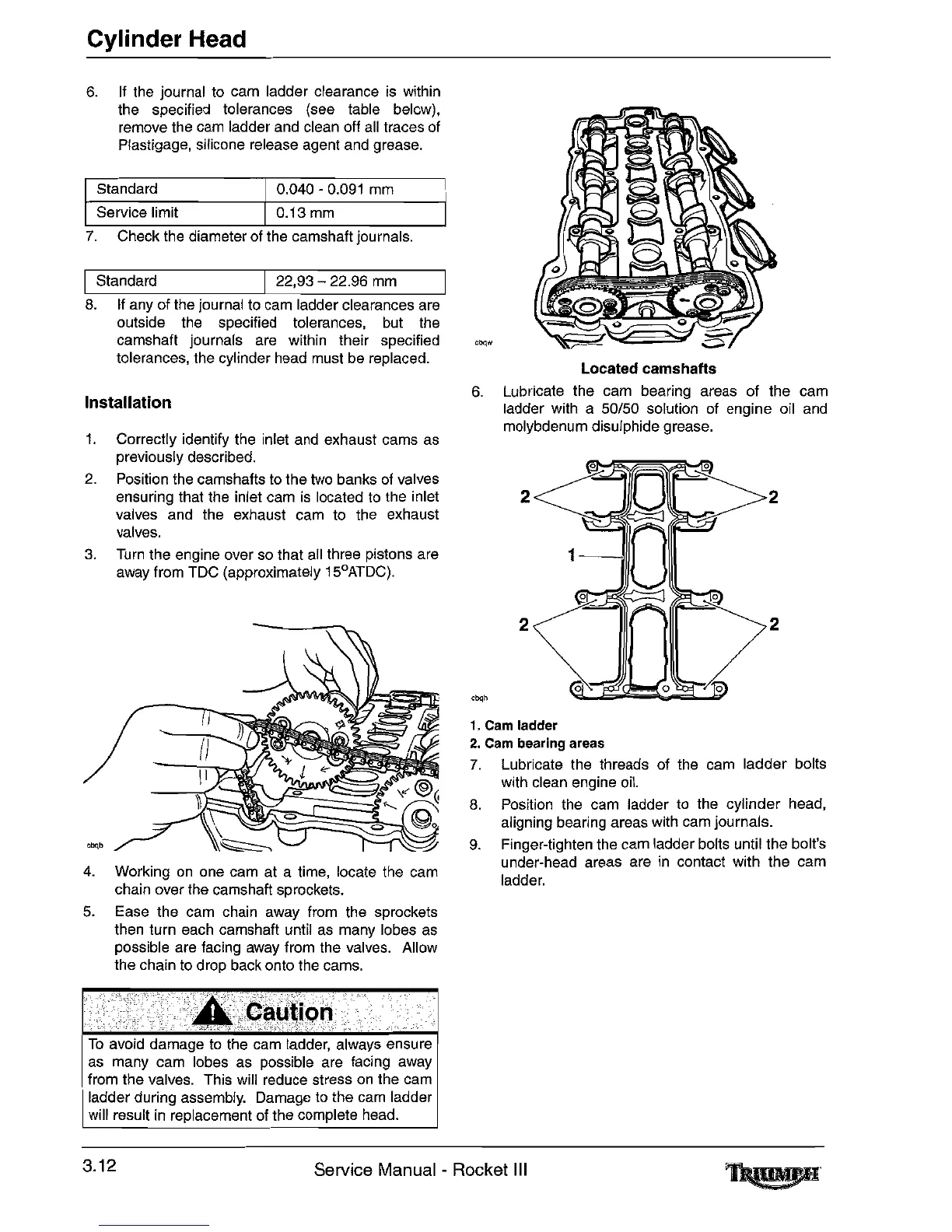

Located camshafts

6.

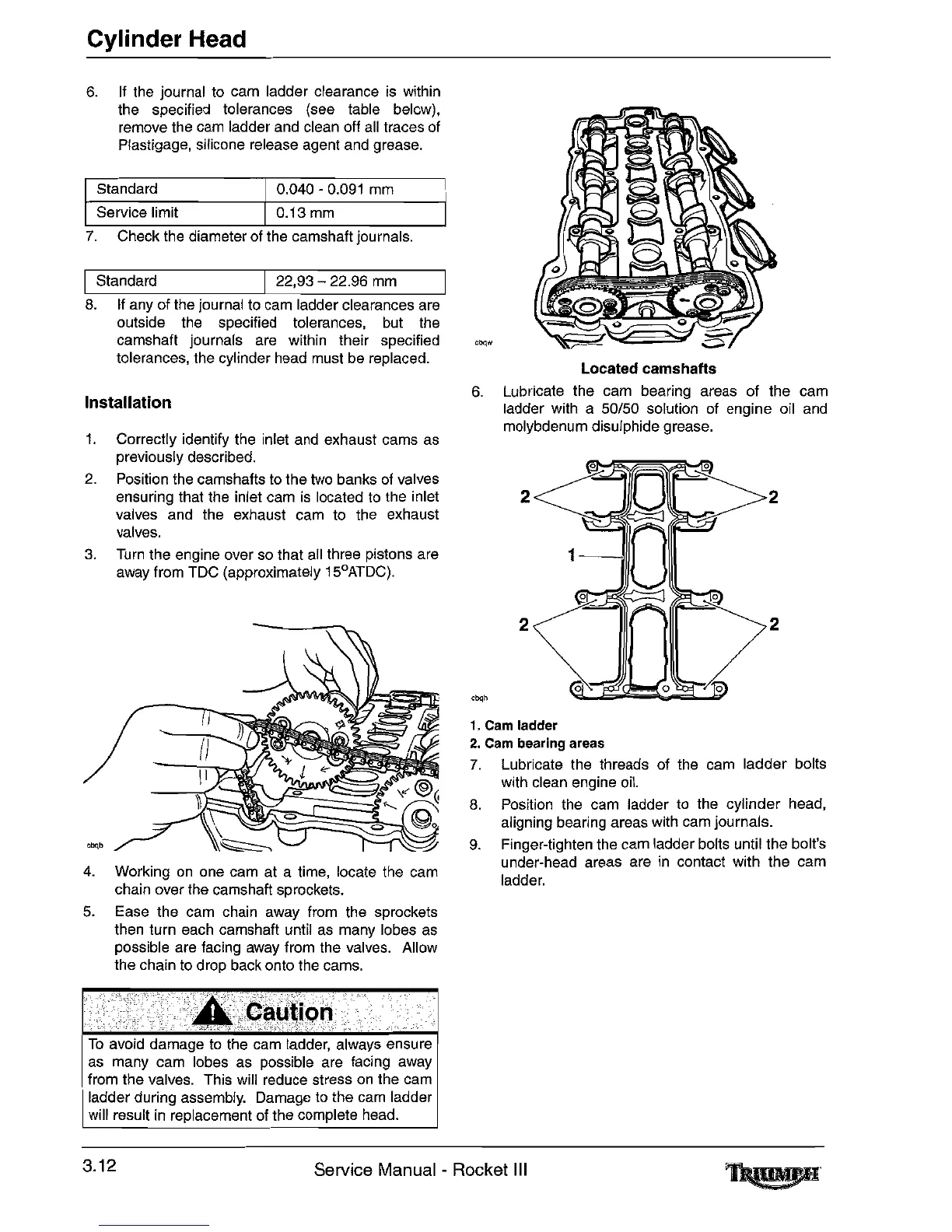

Lubricate the cam bearing areas of the cam

ladder with a

50/50 solution of engine oil

and

molybdenum disulphide grease.

""h

1.

Cam ladder

2.

Cam bearing areas

7.

Lubricate the threads of the cam ladder bolts

with clean engine

oil.

8.

Position the cam ladder

to

the cylinder head,

aligning bearing areas with

cam

journals.

9.

Finger-tighten the cam ladder bolts until the bolt's

under-head areas are

in

contact with the cam

ladder.

0.040 - 0.091

mm

0.13

mm

Standard

Service limit

7.

Check the diameter of the camshaft

Journals.

Installation

6.

If

the

journal

to

cam ladder clearance

is

within

the specified tolerances (see table below),

remove the

cam

ladder and clean off

all

traces

of

Plastigage, silicone release agent

and

grease.

1.

Correctly identify the inlet

and

exhaust cams

as

previously described.

2.

Position the camshafts

to

the

two

banks

of

valves

ensuring that the inlet cam

is

located

to

the inlet

valves and the exhaust cam

to

the exhaust

valves.

3.

Turn

the engine over

so

that

all

three pistons are

away from TDC (approximately 15°ATDC).

4.

Working

on

one cam at a time, locate the cam

chain over the camshaft sprockets.

5.

Ease the cam chain away from the sprockets

then turn each camshaft until

as

many lobes

as

possible are facing away from the valves. Allow

the chain

to

drop back onto the cams.

IStandard I22,93 - 22.96

mm

I

8.

If

any of the journal

to

cam

ladder clearances are

outside the specified tolerances,

but

the

camshaft journals are within their specified

tolerances, the cylinder head must

be

replaced.

To

avoid damage to the cam ladder, always ensure

as many cam lobes as possible are facing away

from the valves. This will reduce stress

on

the

cam

ladder during assembly. Damage

to

the

cam

ladder

will result in replacement of the complete

head.

3.12

Service Manual - Rocket

III

Loading...

Loading...