- 93 -

5 Troubleshooting

5

5.3 Troubleshooting of Faults

Takethecurrentoperationaxis3asanexample.

■ E3.101: system parameter abnormal

Cause:

The total number of parameters changes, which generally occurs after software updates.

The actual parameter values of group 2002h and later exceed the limit, which generally occurs after software

updates.

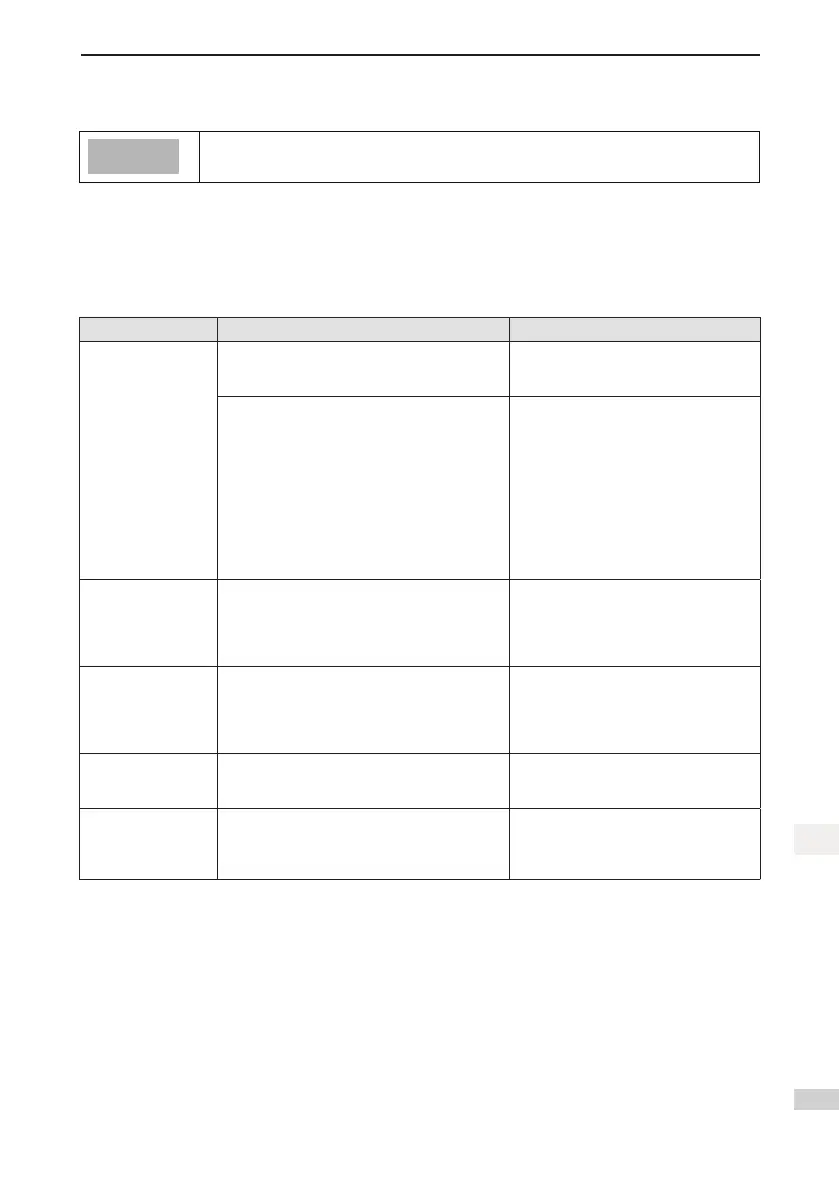

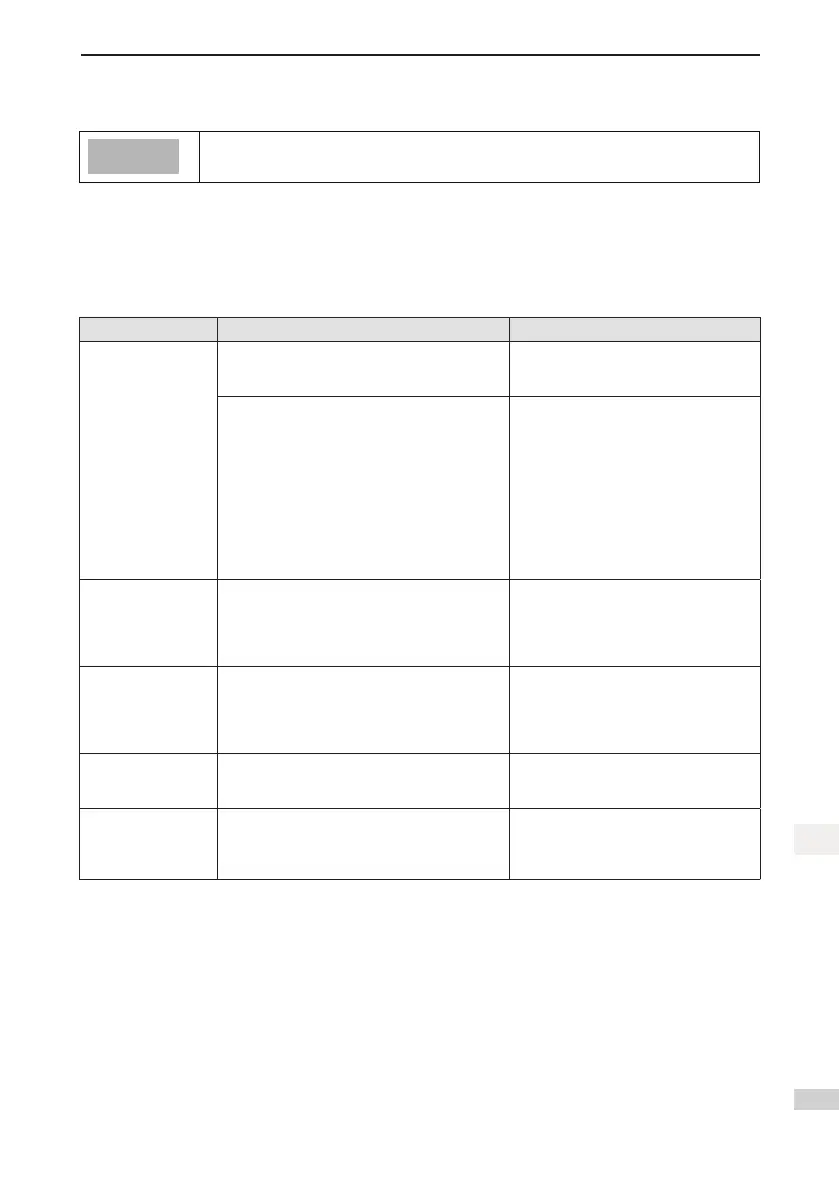

Probable Cause ConrmingMethod Corrective Action

1. The control power

voltage drops

instantaneously.

Checkwhetherthecontrolpower(L1C,L2C)is

cut off or whether an instantaneous power failure

occurs.

Restore the default setting (2002-20h=1),

and rewrite the parameters.

Measure whether the control power voltage

on the non-drive side is within the following

specications:

220Vdrive:

Effectivevalue:220Vto240V

Allowederror:–10%to+10%(198Vto264V)

380Vdrive:

Effectivevalue:380V–440V

Allowederror:–10%to+10%(342Vto484V)

Increase the power capacity or replace

with a large-capacitance power supply.

Restore the default setting (2002-20h=1),

and rewrite the parameters.

2. Instantaneous

power failure

occurs during

parameter

storage.

Checkwhetherinstantaneouspowerfailure

occurs during parameter storage.

Power on the system again, restore the

default setting (2002-20h=1), and rewrite

the parameters.

3. The times of

parameter writing

within a certain

period exceeds the

limit.

Checkwhethertheparameterupdateis

performed frequently from the host controller.

Change the parameter writing method

and rewrite parameters.

If the servo drive is faulty, replace it.

4. The software is

upgraded.

Checkwhetherthesoftwareisupgraded.

Reset the servo drive model and the

servo motor model, and restore the

default setting (2002-20h=1).

5. The servo drive is

faulty.

If the servo drive is powered off and powered on

several times and the default setting is restored,

but the fault persists, it indicates that the servo

drive is faulty.

Replace the servo drive.

Loading...

Loading...