Goodrive35 Series Closed-loop Vector Control VFD Basic operation instruction

187

PID parameter setting for detailed information) to make proportional adjustment is the only method to

PID. Set the input as 60%–70% of the permitted max value and increase gain P from 0 until the

system vibration occurs, vice versa, and record the PID value and set it to 60%–70% of the current

value. Then the gain P commission is finished.

2. Ensure the integral time Ti

After ensuring the gain P, set an original value of a bigger integral time and decrease it until the

system vibration occurs, vice versa, until the system vibration disappear. Record the Ti and set the

integral time to 150%–180% of the current value. Then integral time commission is finished.

3. Ensure the derivative time Td

Generally, it is not necessary to set Td which is 0.

If it needs to be set, set it to 30% of the value without vibration via the same method with P and Ti.

4. Commission the system with and without load and then adjust the PID parameter until it is

available.

7.15.2 PID inching

After setting the PID control parameters, inching is possible by following means:

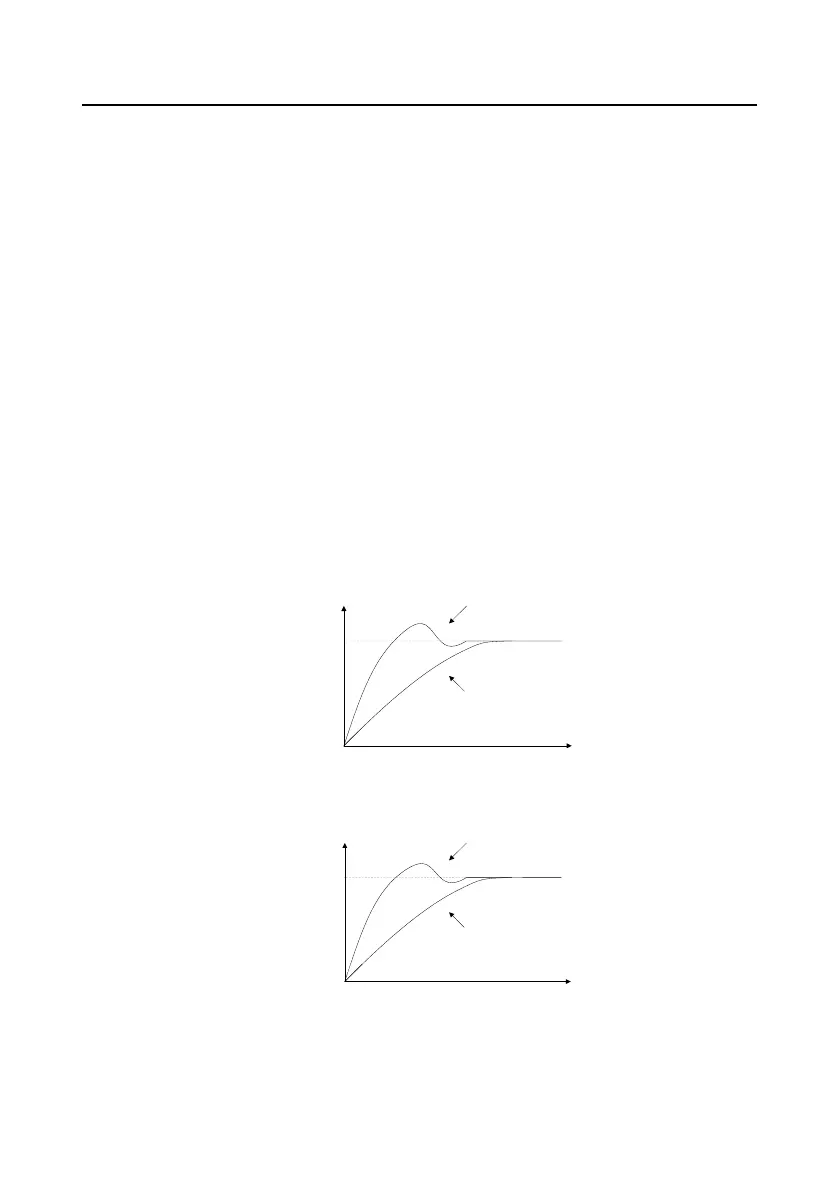

Control overmodulation: Shorten the derivative time and prolong the integral time when overshoot

occurs.

Before adjustment

After adjustment

Response

Time t

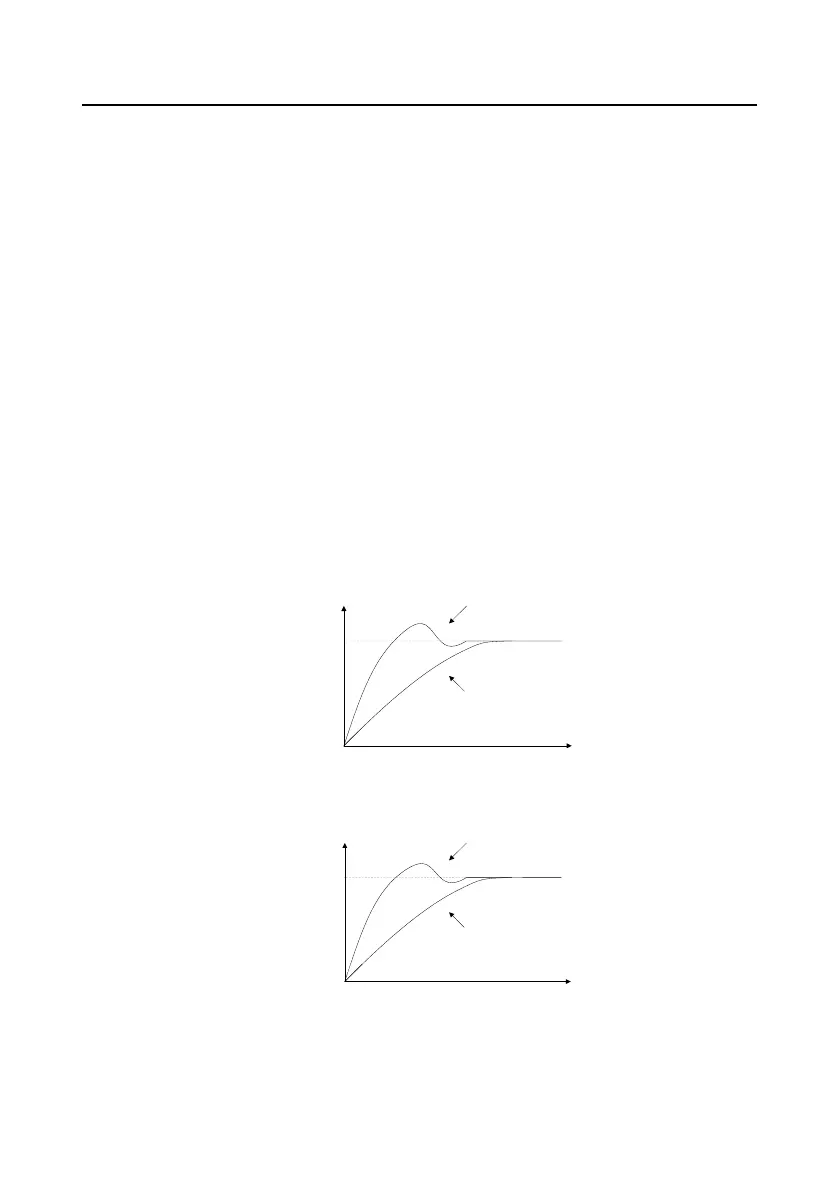

Achieve the stable state as soon as possible: Shorten the integral time (Ti) and prolong the

derivative time (Td) even the overshoot occurs, but the control should be stable as soon as possible.

Before adjustment

After adjustment

Response

Time t

Control long vibration: If the vibration periods are longer than the set value of integral time (Ti), it is

necessary to prolong the integral time (Ti) to control the vibration for the strong integration.

Loading...

Loading...