Goodrive35 Series Closed-loop Vector Control VFD Communication protocol

231

After receiving the command, the VFD converts 50 into 5.0 based on the fieldbus scale, and then sets

"Wake-up-from-sleep delay" to 5.0s.

For another example, after the upper computer transmits the "Wake-up-from-sleep delay" parameter

read command, the master receives the following response from the VFD:

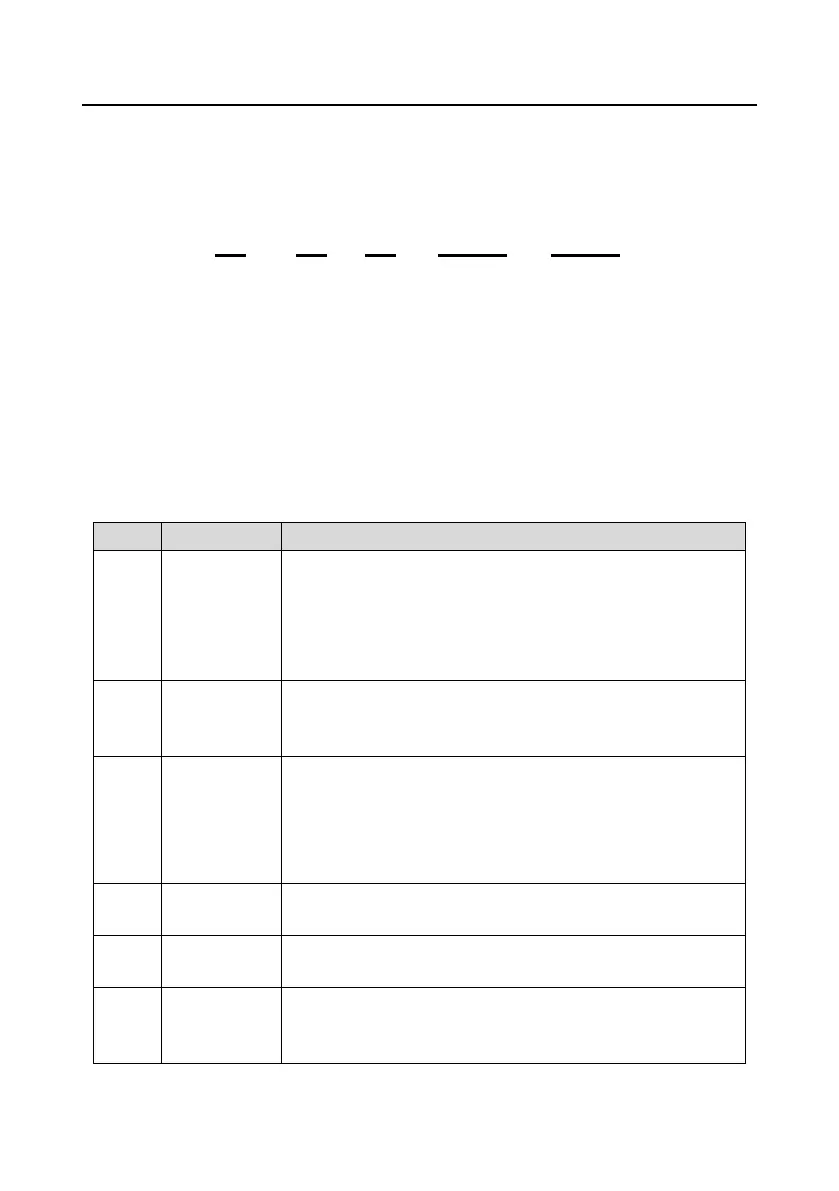

VFD

address

Read

command

Parameter

data

CRC check

2-byte

data

01 03 02 00 32 39 91

The parameter data is 0032H, that is, 50, so 5.0 is obtained based on the fieldbus scale (50/10=5.0).

In this case, the master identifies that the "Wake-up-from-sleep delay" is 5.0s.

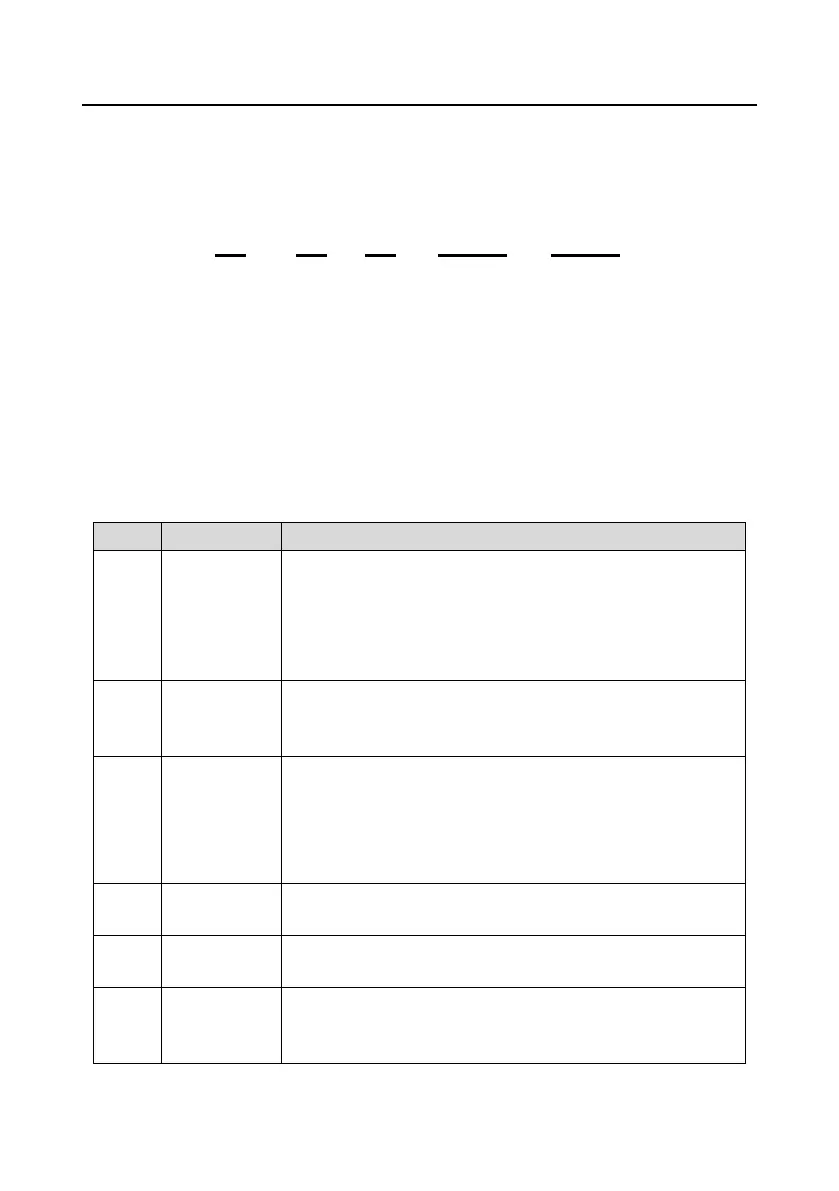

10.4.7 Fault message response

Operation errors may occur in communication-based control. For example, some parameters can

only be read, but a write command is transmitted. In this case, the VFD returns an error message

response.

Error message responses are transmitted by the VFD to the master. The following table describes the

codes and definitions of the error message responses.

The command code received by the upper computer is not allowed

to be executed. The possible causes are as follows:

• The function code is applicable only on new devices and is not

implemented on this device.

• The slave is in the faulty state when processing this request.

For the VFD, the data address in the request of the upper computer

is not allowed. In particular, the combination of the register address

and the number of the to-be-transmitted bytes is invalid.

The received data domain contains a value that is not allowed. The

value indicates the error of the remaining structure in the combined

request.

Note: It does not mean that the data item submitted for storage in

the register includes a value unexpected by the program.

The parameter is set to an invalid value in the write operation. For

example, a function input terminal cannot be set repeatedly.

The password entered in the password verification address is

different from that set in P07.00.

The length of the data frame transmitted by the upper computer is

incorrect, or in the RTU format, the value of the CRC check bit is

inconsistent with the CRC value calculated by the lower computer

Loading...

Loading...