Goodrive35 Series Closed-loop Vector Control VFD Communication protocol

224

A piece of data is two bytes, with the MSB on the left and LSB on the right. From the response, we

can see that the data in 0004H is 1388H, and that in 0005H is 0000H.

CRC check occupies two bytes, with the LSB on the left, and MSB on the right.

10.4.2 Command code: 06H, writing a word

This command is used by the master to write data to the VFD. One command can be used to write

only one piece of data. It is used to modify the parameters and operation mode of the VFD.

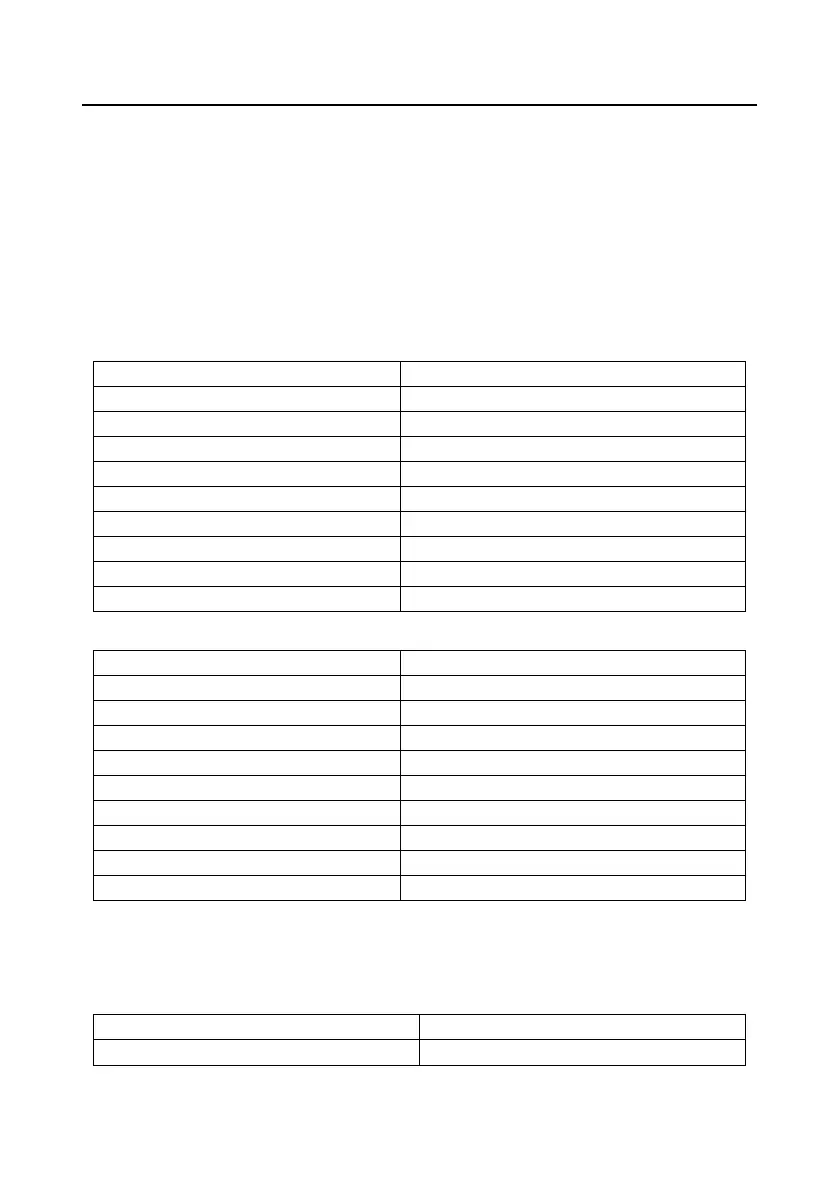

For example, to write 5000 (1388H) to 0004H of the VFD whose address is 02H, the structure of the

frame is described in the following table.

RTU master command (transmitted by the master to the VFD)

T1-T2-T3-T4 (transmission time of 3.5 bytes)

MSB of data writing address

LSB of data writing address

MSB of to-be-written data

LSB of to-be-written data

T1-T2-T3-T4 (transmission time of 3.5 bytes)

RTU slave response (transmitted by the VFD to the master)

T1-T2-T3-T4 (transmission time of 3.5 bytes)

MSB of data writing address

LSB of data writing address

MSB of to-be-written data

LSB of to-be-written data

T1-T2-T3-T4 (transmission time of 3.5 bytes)

Note: Section 10.2 and 10.3 mainly describe the command format, and the detailed application will be

mentioned in 10.4.8 with examples.

10.4.3 Command code: 08H, diagnosis

Sub-function code description

Return data based on query requests

Loading...

Loading...