Goodrive35 Series Closed-loop Vector Control VFD Communication protocol

230

Note: Some parameters in the preceding table are valid only after they are enabled. Take the running

and stop operations as examples, you need to set "Running command channel" (P00.01) to

"Communication", and set "Communication running command channel" (P00.02) to the Modbus

communication channel. For another example, when modifying "PID setting", you need to set "PID

reference source" (P09.00) to Modbus communication.

The following table describes the encoding rules of device codes (corresponding to the identification

code 2103H of the VFD).

10.4.6 Fieldbus ratio values

In practical applications, communication data is represented in the hexadecimal form, but

hexadecimal values cannot represent decimals. For example, 50.12 Hz cannot be represented in the

hexadecimal form. In such cases, we can multiply 50.12 by 100 to obtain an integer 5012, and then

50.12 can be represented as 1394H (5012 in the decimal form) in the hexadecimal form.

In the process of multiplying a non-integer by a multiple to obtain an integer, the multiple is referred to

as a fieldbus scale.

The fieldbus scale depends on the number of decimals in the value specified in "Detailed parameter

description" or "Default value". If there are n decimals in the value, the fieldbus scale m is the

n

th

-power of 10. Take the following table as an example, m is 10.

Detailed parameter description

Hibernation restore

delay time

0.0–3600.0s (valid when P01.19 is

2)

0: Restart is disabled

1: Restart is enabled

The value specified in "Detailed parameter description" or "Default value" contains one decimal, so

the fieldbus scale is 10. If the value received by the upper computer is 50, the value of

"Wake-up-from-sleep delay" of the VFD is 5.0 (5.0=50/10).

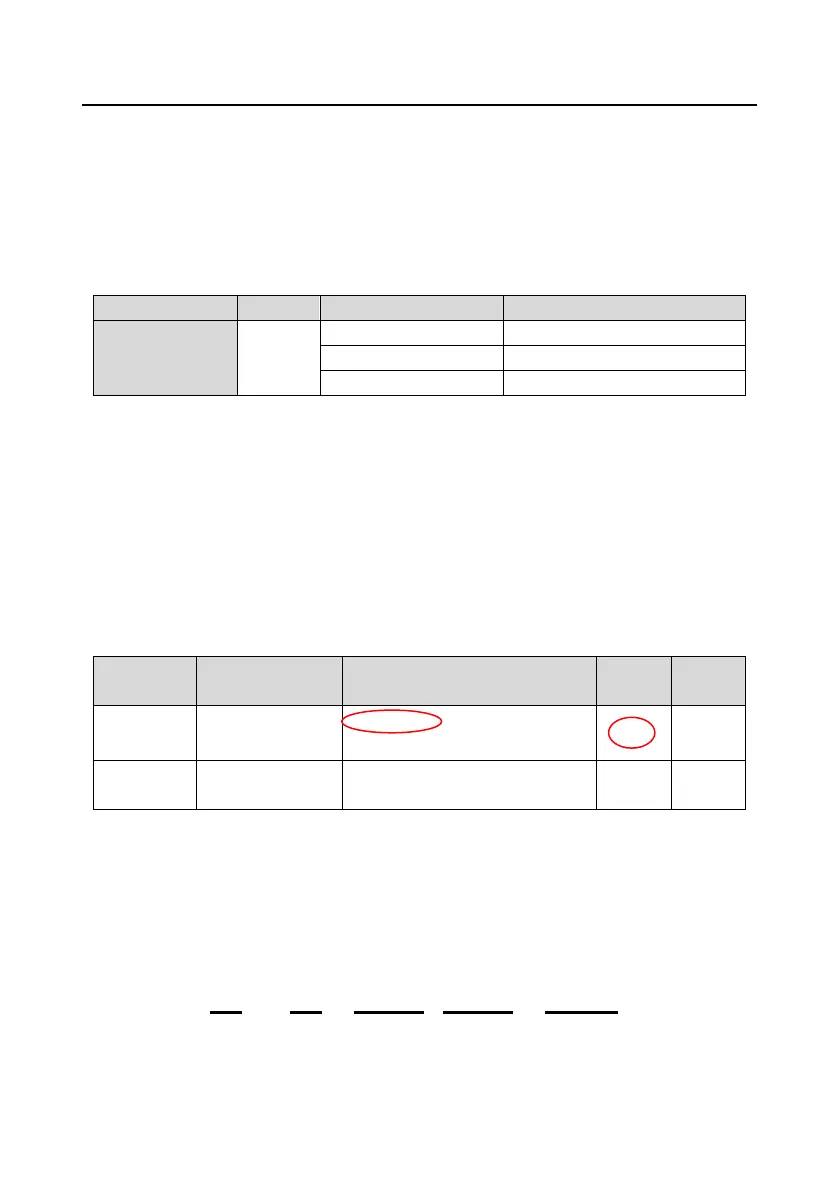

To set the "Wake-up-from-sleep delay" to 5.0s through Modbus communication, you need first to

multiply 5.0 by 10 according to the scale to obtain an integer 50, that is, 32H in the hexadecimal form,

and then transmit the following write command:

VFD

address

Write

command

Parameter

address

Parameter

data

CRC check

01 06 01 14 00 32 49 E7

Loading...

Loading...