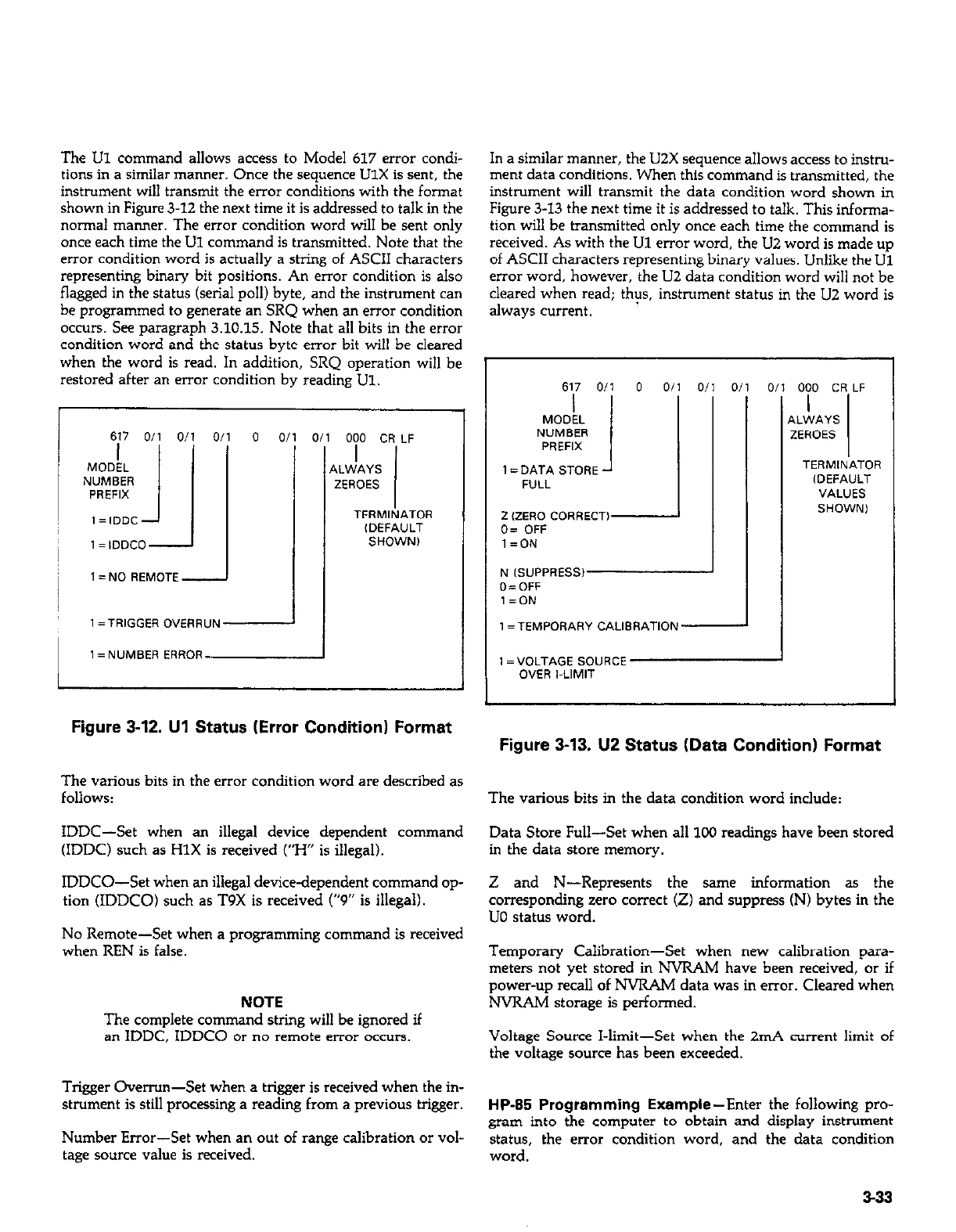

The Ul command allows access to Model 617 error condi-

tions in a similar manner. Once the sequence UlX is sent, the

instrument will transmit the error conditions with the format

shown in Figure 3-12 the next time it is addressed to talk in the

normal manner. The error condition word will be sent only

once each time the Ul command is transmitted. Note that the

error condition word is actually a string of ASCII characters

representing binary bit positions. An error condition is also

flagged in the status (serial poll) byte, and the instrument can

be programmed to generate an SRQ when a” error condition

OCCWS. See paragraph 3.10.15. Note that all bits in the error

condition word and the status byte error bit will be cleared

when the word is read. In addition, SRQ operation will be

restored after an error condition by reading Ul.

r

617 Oil O/l 0,

I= IDDCO-

1= NO REMOTE -

0 0

1 1 = NUMBER ERROR

000 CR LF

,LWAYS

ZEROES

TERMINATOR

(DEFAULT

SHOWN1

1

Figure 3-12. Ul Status (Error Condition) Format

The various bits in the error condition word are described as

follows:

IDDC-Set when a” illegal device dependent command

(IDDC) such as HlX is received (“H” is illegal).

IDDCO-Set when a” illegal device-dependent command op-

tion (IDDCO) such as T9X is received (“9” is illegal).

No Remote-Set when a programming command is received

when REN is false.

NOTE

The complete command string will be ignored if

an IDDC. IDDCO or no remote error occurs.

Trigger Overrun-Set when a trigger is received when the in-

strument is still processing a reading from a previous trigger.

Number Error-Set when a” Out of range calibration or vol-

tage source value is received.

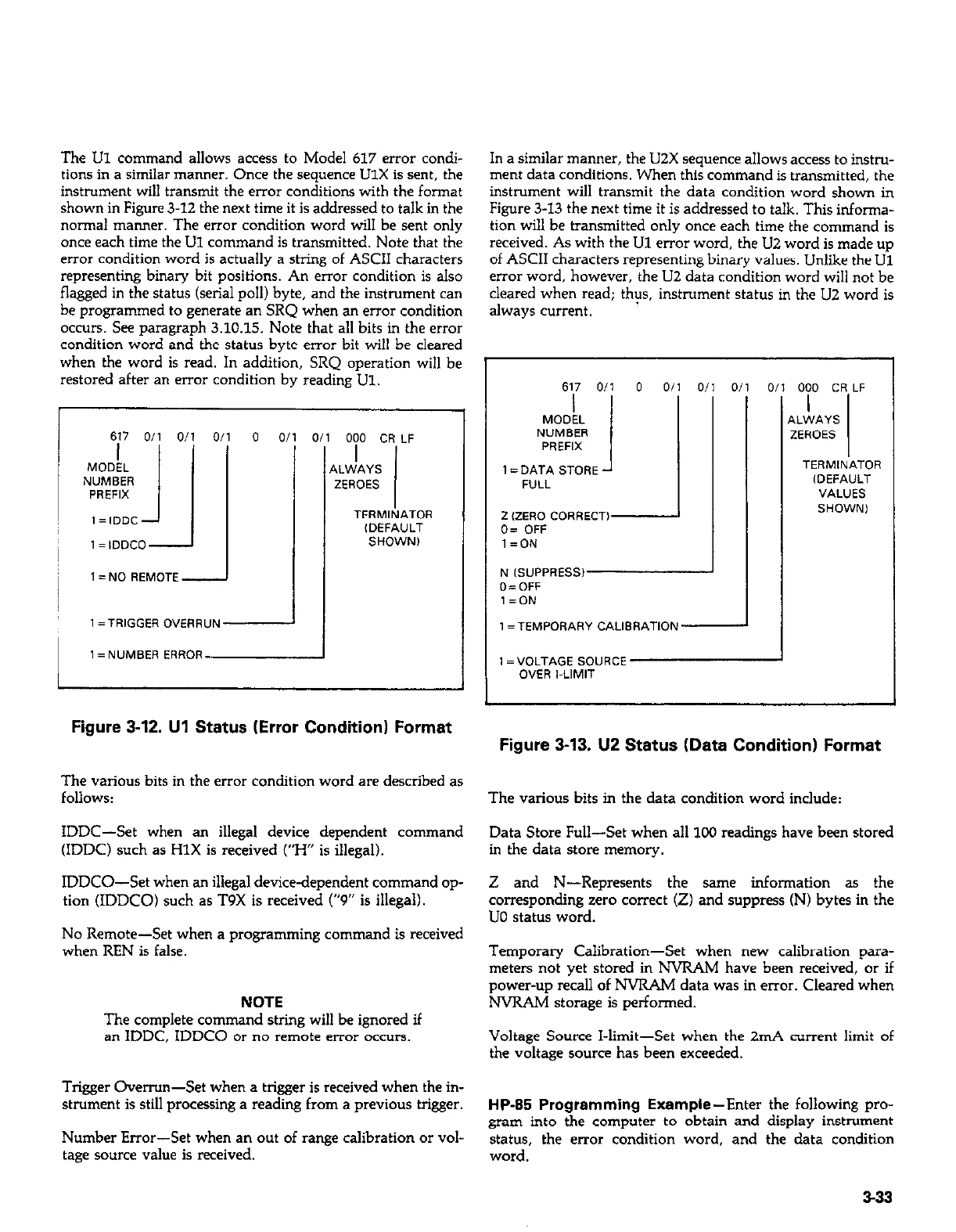

In a similar manner, the U2X sequence allows access to instru-

ment data conditions. When this command is transmitted, the

instrument will transmit the data condition word shown in

Figure 3-13 the next time it is addressed to talk. This informa-

tion will be transmitted only once each time the command is

received. As with the Ul error word, the U2 word is made up

of ASCII characters representing binary values. Unlike the Ul

error word, however, the LIZ data condition word will not be

cleared when read; thps, instrument status in the U2 word is

always current.

617 Oil 0 Oil o/1 0.

MODEL

NUMBER

PREFIX

1 = DATA STORE J

FULL

2 (ZERO CORRECT)

0= OFF

l=ON

N (SUPPRESS1

O=OFF

l=ON

1 =TEMPORARY CALlSRATlON-

0,

iI

1 =“OLTAGE SOURCE

OVER I-LIMIT

A

000 CR LF

I

.LWAYS

!EROES

TERMINATOR

,DEFAULT

VALUES

1

Figure 3-13. U2 Status (Data Condition) Format

The various bits in the data condition word include:

Data Store Full-Set when all 100 readings have been stored

in the data store memory.

Z and N-Represents the same information as the

corresponding zero correct (Z) and suppress (N) bytes in the

UO status word.

Temporary Calibration-Set when new calibration para-

meters not yet stored in NVRAM have been received, or if

power-up recall of NVRAM data was in error. Cleared when

NVRAM storage is performed.

Voltage Source I-limit-Set when the 2mA current limit of

the voltage source has been exceeded.

HP-85 Programming Example-Enter the following pro-

gram into the computer to obtain and display instrument

status, the error condition word, and the data condition

word.

3-33

Loading...

Loading...