Limit Testing 11-13

Multiple-element device binning

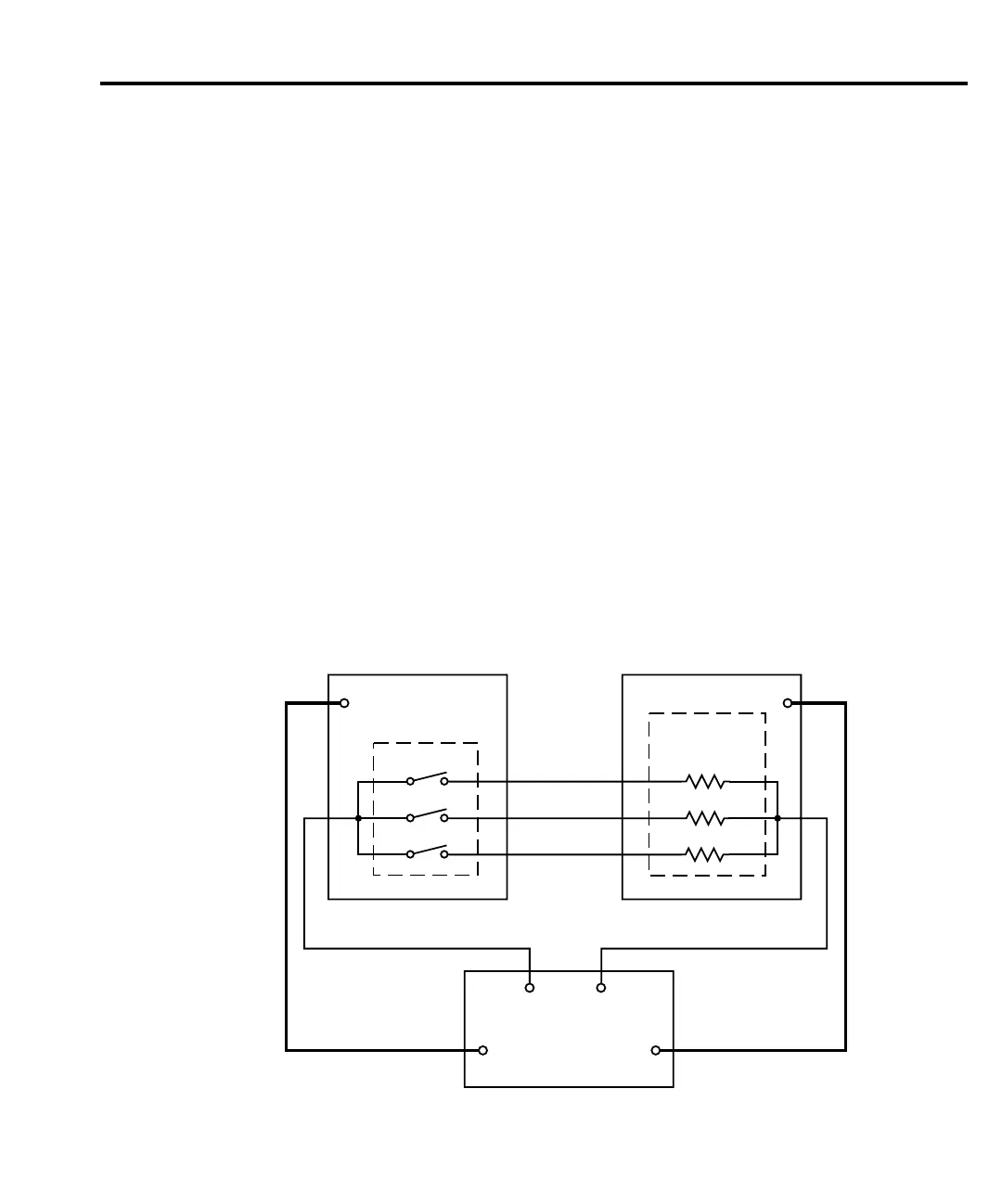

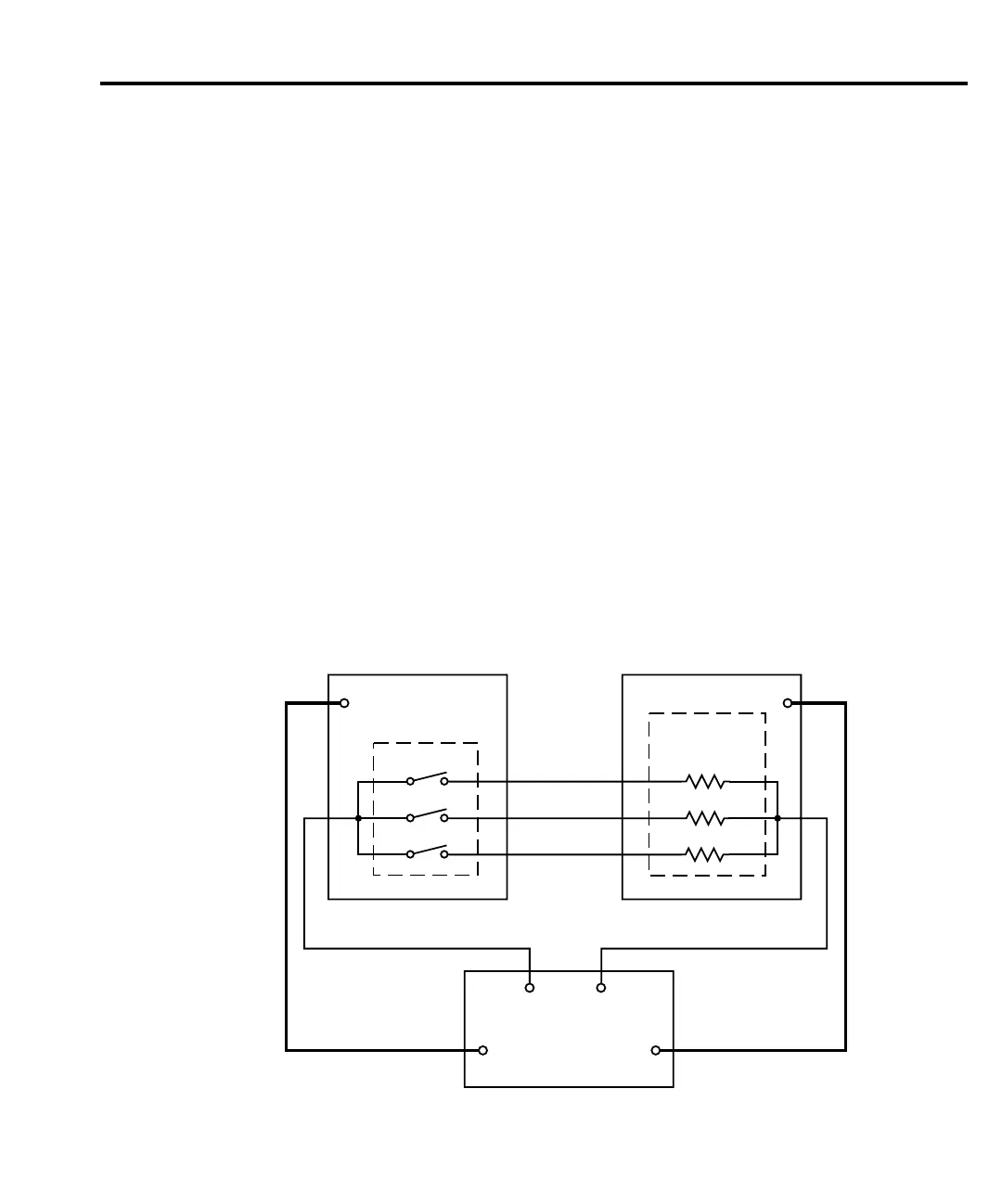

Figure 11-8 shows a basic binning system to test three-element resistor networks. Note that

this system requires a scanner card that is installed in a switching mainframe. Scanner card

switching is controlled through the Trigger Link. End binning control is required for this test

system, therefore, the grading mode must be used.

Trigger operations for the scanner and SourceMeter must be configured appropriately for

this test. In general, the scanner must be configured to scan three channels, and the Source-

Meter must be configured to perform a 3-point sweep and output a trigger to the scanner after

each measurement. See Section 10 for details.

When the testing process is started, Ch 1 of the scanner card closes, and R1 is measured.

Two events occur concurrently after the measurement is completed: R1 is tested, and the

SourceMeter sends a trigger pulse to the switching mainframe causing Ch 1 to open and Ch 2

to close. Assuming there is no failure, a measurement is then performed on R2. While R2 is

being tested, Ch 2 opens and Ch 3 closes. Again assuming no failure, a measurement is per-

formed on R3 and it is then tested. Assuming that all the tests on all three resistors passed, the

device package is placed in the pass bin.

If any of the resistors in the network fails a test, the FAIL message is displayed, and the dig-

ital output information for the first failure is stored in memory (assuming that END binning

control is selected). After the sweep is completed, the SourceMeter sends the output pattern

stored in memory. This is the output pattern for the first test failure. The component handler

places the DUT package into the bin assigned to that particular failure.

The handler selects the next resistor network, and the testing process is repeated.

Switching Mainframe Handler

Trigger

Link

Scanner Card

Ch 1

Ch 2

Ch 3

Dig

In

Multi-Element

Device Package

R1

R2

R3

In/Out

HI LO

Trigger

Link *

Dig

I/O

6430

* Trigger layer configured to output trigger pulse after each measurement.

Figure 11-8

Binning system -

multiple element

devices

Loading...

Loading...