Installation

4-13

SHB9300CRV EN 2.0

4.2.7 Power connections

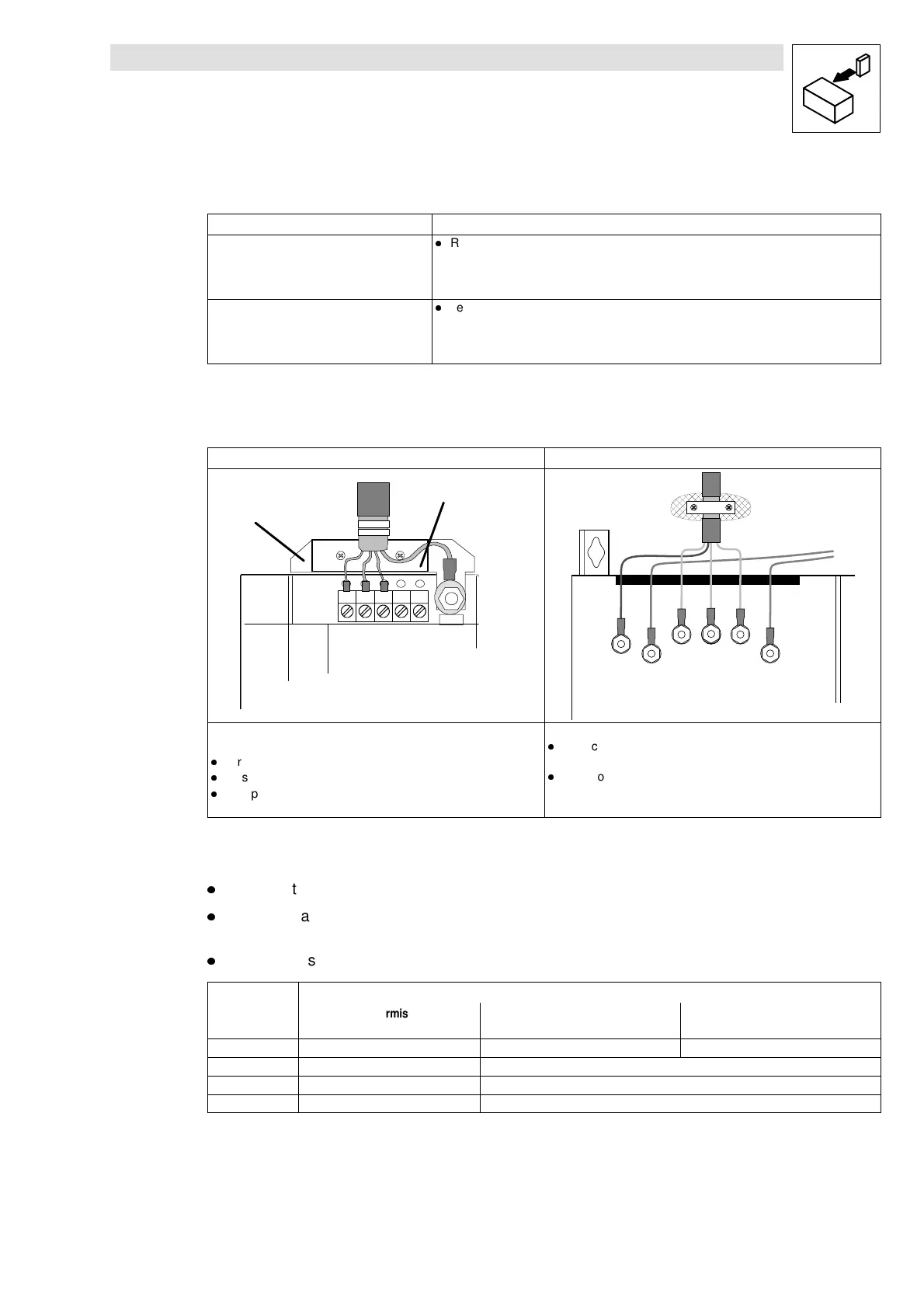

Controller Preparations for the power connection

9321 ... 9326

l

Remove the covers of the power connections:

– Unlatch to the front by gentle pressure.

– Pull upwards (mains connection) or downwards (motor connection).

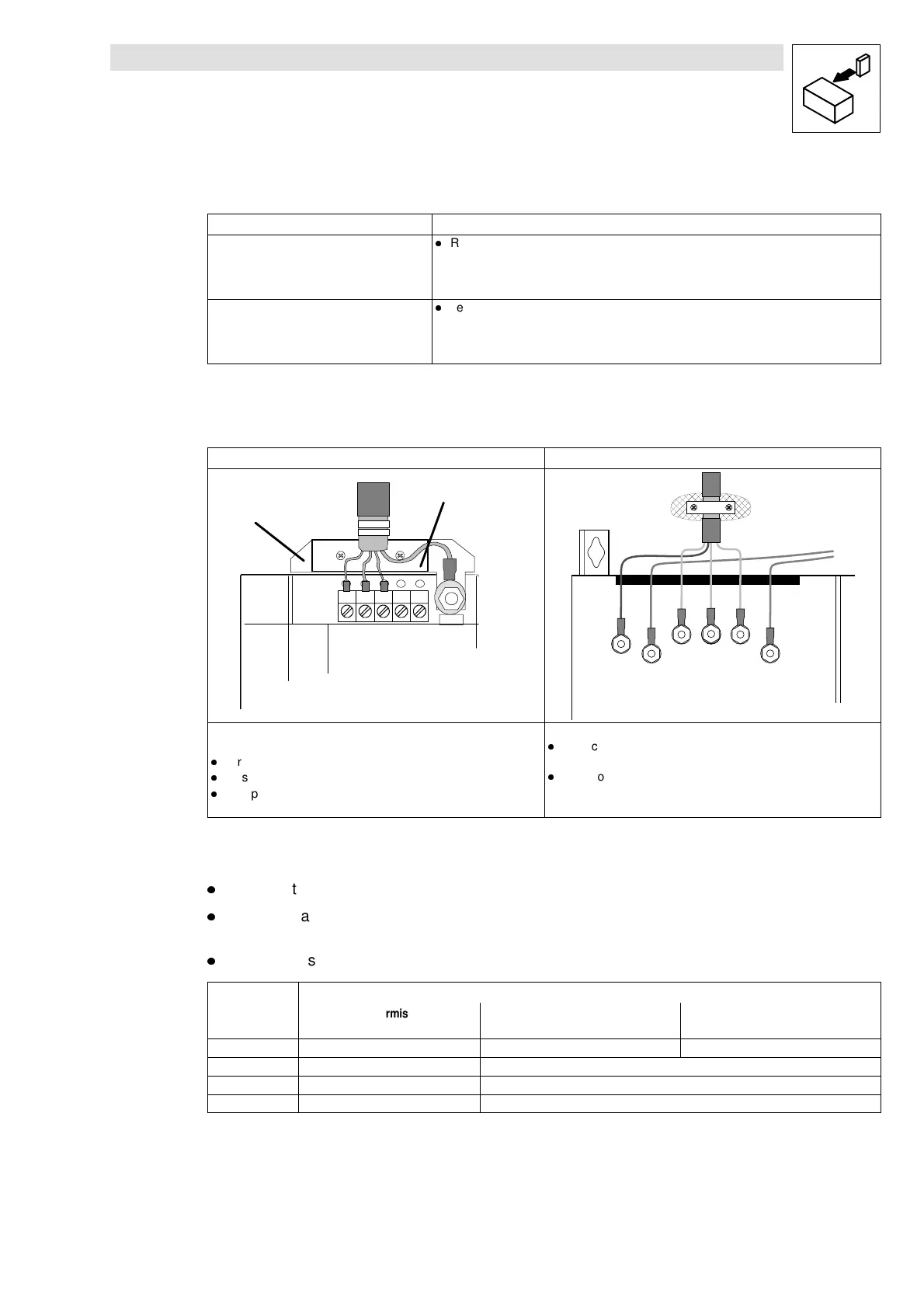

9327 ... 9332

l

Remove cover:

– Loosen screws (X) (see Fig. 4-1).

– Swing cover to the top and detach.

– Take the accessory kit out of the interior of the controller.

4.2.7.1 Mains connection

Types 9321 to 9326 Types 9327 to 9332

PE

L1 L2 L3

-UG+UG

➀

➁

PE

+UG

-UG

L1

L2

L3

Correct screen connection with screened cables

(required parts in the accessory kit):

l

Screw sreen plate on fixing bracket ó .

l

Fix screen using cable lugs. Do not use as a strain relief!

l

To improve the screen connection: Connect screen additionally at

the stud next to the power connections.

Correct screen connection with screened cables:

l

Connect the screen with suitable clamp on the conducting control

cabinet mounting plate.

l

To improve the screen connection: Connect screen additionally at

the stud next to the power connections.

Fig. 4-7 Proposal for mains connection

l

Connect the mains cables to the screw terminals L1, L2, L3.

l

Connect cables for brake unit (935X), supply module (934X) or further controllers in the DC

bus connection to the screw terminals +UG, -UG at the top of the controller.

l

Max. permissible cable cross-sections and tightening torques:

Type Terminals

Max. permissible

vable cross-sections

L1, L2, L3, +UG, -UG PE connection

9321 - 9326 4mm

21)

0.5 ... 0.6 Nm (4.4 ... 5.3 lbin) 3.4 Nm (30 lbin)

9327 - 9329 25 mm

22)

4 Nm (35 lbin)

9330 - 9331 95 mm

22)

7 Nm (62 lbin)

9332 120 mm

22)

12 Nm (106.2 lbin)

1)

with pin-end connector: 6 mm

2

with wire crimp cap 4 mm

2

2)

with ring cable lug The cross-section is only limited by the cable cut-out in the housing.

Loading...

Loading...