3 - 28

Ân

250H - PERIODIC MAINTENANCE - EVERY 250 HOURS OF SERVICE OR 6 MONTHS

ALSO PERFORM THE DAILY MAINTENANCE.

CHECK Injection pipes, fuel hoses and the hose clamps

50H: MONTHLY MAINTENANCE OR EVERY 50 HOURS OF SERVICE.

CHECK Reduction gearbox impermeability

50H: MONTHLY MAINTENANCE OR EVERY 50 HOURS OF SERVICE.

CHECK Impermeability of the front and rear axle differentials

50H: MONTHLY MAINTENANCE OR EVERY 50 HOURS OF SERVICE.

CHECK Impermeability of the front and rear gear reducers

50H: MONTHLY MAINTENANCE OR EVERY 50 HOURS OF SERVICE.

CHECK Generator (OPTION)

50H: MONTHLY MAINTENANCE OR EVERY 50 HOURS OF SERVICE.

CHECK Wheel nut tightening

IMPORTANT

Failure to follow this instruction may result in the machine tipping over.

The tightening of the wheel nuts should be checked at the latest after the first 50 hours of service, then every 250 hours of service.

- Check all the wheel nut tightening torques:

550N.m ±55N.m

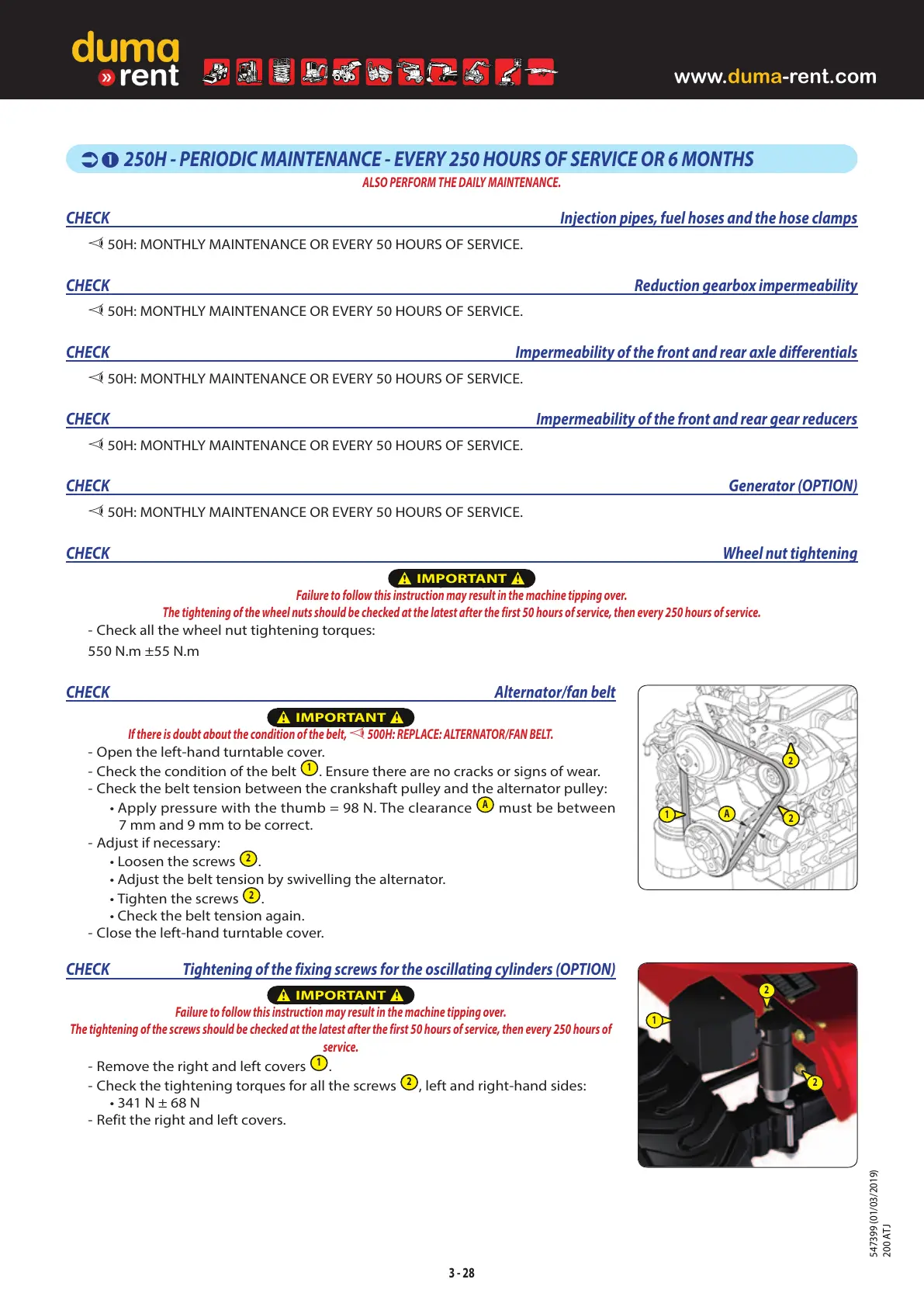

CHECK Alternator/fan belt

IMPORTANT

If there is doubt about the condition of the belt,

500H: REPLACE: ALTERNATOR/FAN BELT.

- Open the left-hand turntable cover.

- Check the condition of the belt

1

. Ensure there are no cracks or signs of wear.

- Check the belt tension between the crankshaft pulley and the alternator pulley:

• Apply pressure with the thumb= 98N. The clearance

A

must be between

7mm and 9mm to be correct.

- Adjust if necessary:

• Loosen the screws

2

.

• Adjust the belt tension by swivelling the alternator.

• Tighten the screws

2

.

• Check the belt tension again.

- Close the left-hand turntable cover.

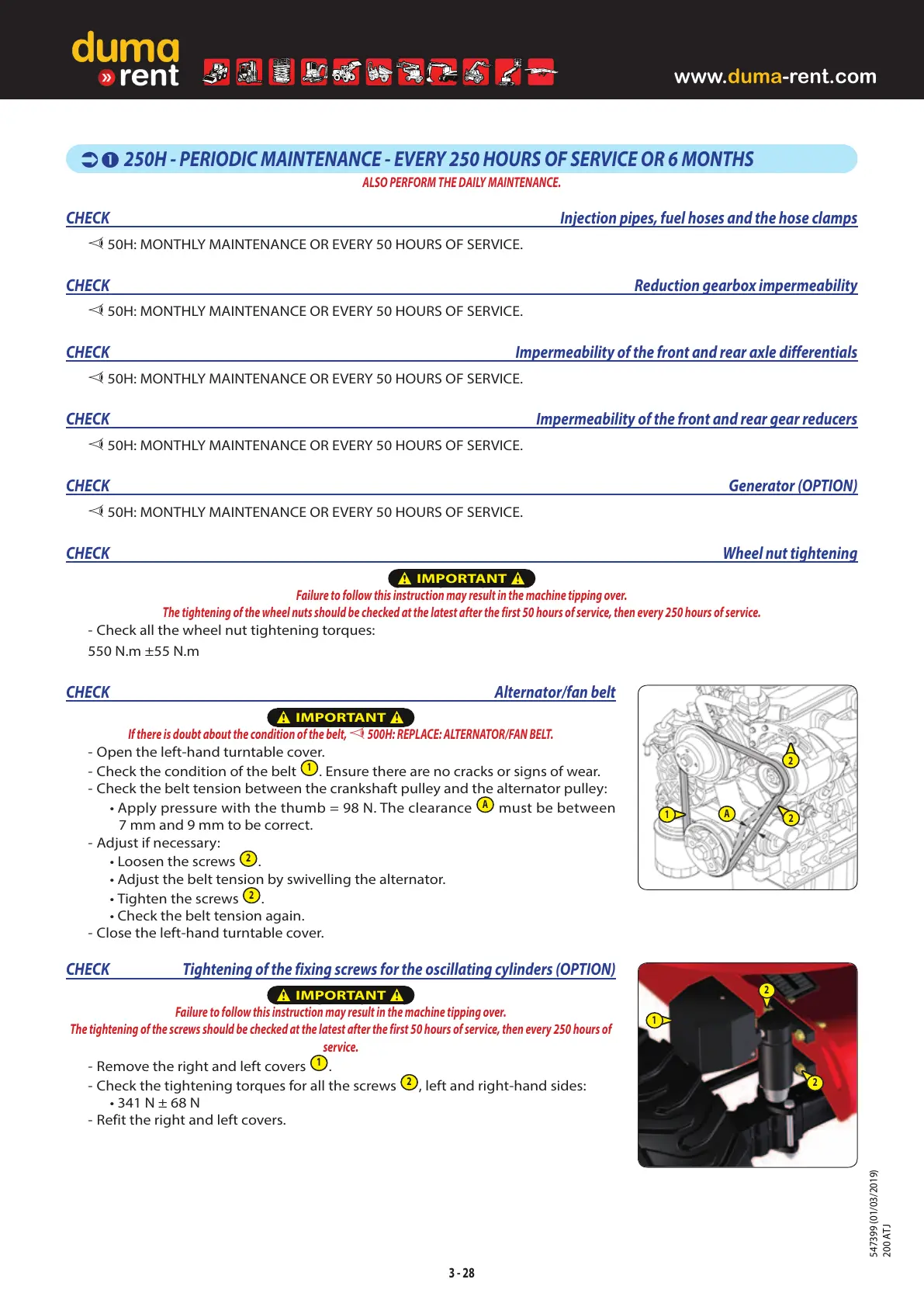

CHECK Tightening of the fixing screws for the oscillating cylinders (OPTION)

IMPORTANT

Failure to follow this instruction may result in the machine tipping over.

The tightening of the screws should be checked at the latest after the first 50 hours of service, then every 250 hours of

service.

- Remove the right and left covers

1

.

- Check the tightening torques for all the screws

2

, left and right-hand sides:

• 341N ± 68N

- Refit the right and left covers.

A

2

2

1

2

1

2

Loading...

Loading...