3 - 31

CHECK Overload alarm

IMPORTANT

Refer to the platform repair manual if the overload alarm is not correctly calibrated.

NOTE: The platform is in the transport position. The turntable and the basket should be in the neutral position. The jib is

completely lowered.

- Switch on the platform. Start the engine.

- Place a uniformly distributed 253 kg weight in the basket.

Result:

• The overload alarm should go off.

• It must not be possible for the controls to be actioned by the control panels on the ground and in the basket.

- Remove 23 kg to obtain a load of 230 kg in the basket.

Result:

• The overload alarm should stop.

• It should be possible to activate the controls.

- Remove the entire load from the basket.

CHECK Braking

NOTE: The engine has been started. The platform is in the transport position. The turntable and the basket are in neutral

position. The jib is completely lowered.

PLACING IN FREEWHEEL MODE

- Perform the freewheel and brake function restoration procedure,

OCCASIONAL OPERATION: PLATFORM WINCHING.

STOPPING DISTANCE ON LEVEL GROUND

- Place a uniformly distributed weight in the basket:

• Place 230kg less the operator's weight.

- Drive the platform forward, reach maximum speed and then release the joystick to stop the platform.

Required results:

Stopping distance

Transport position: HARE speed

1,400mm ± 300mm

Working position: WORKING POSITION speed 200mm ± 50mm

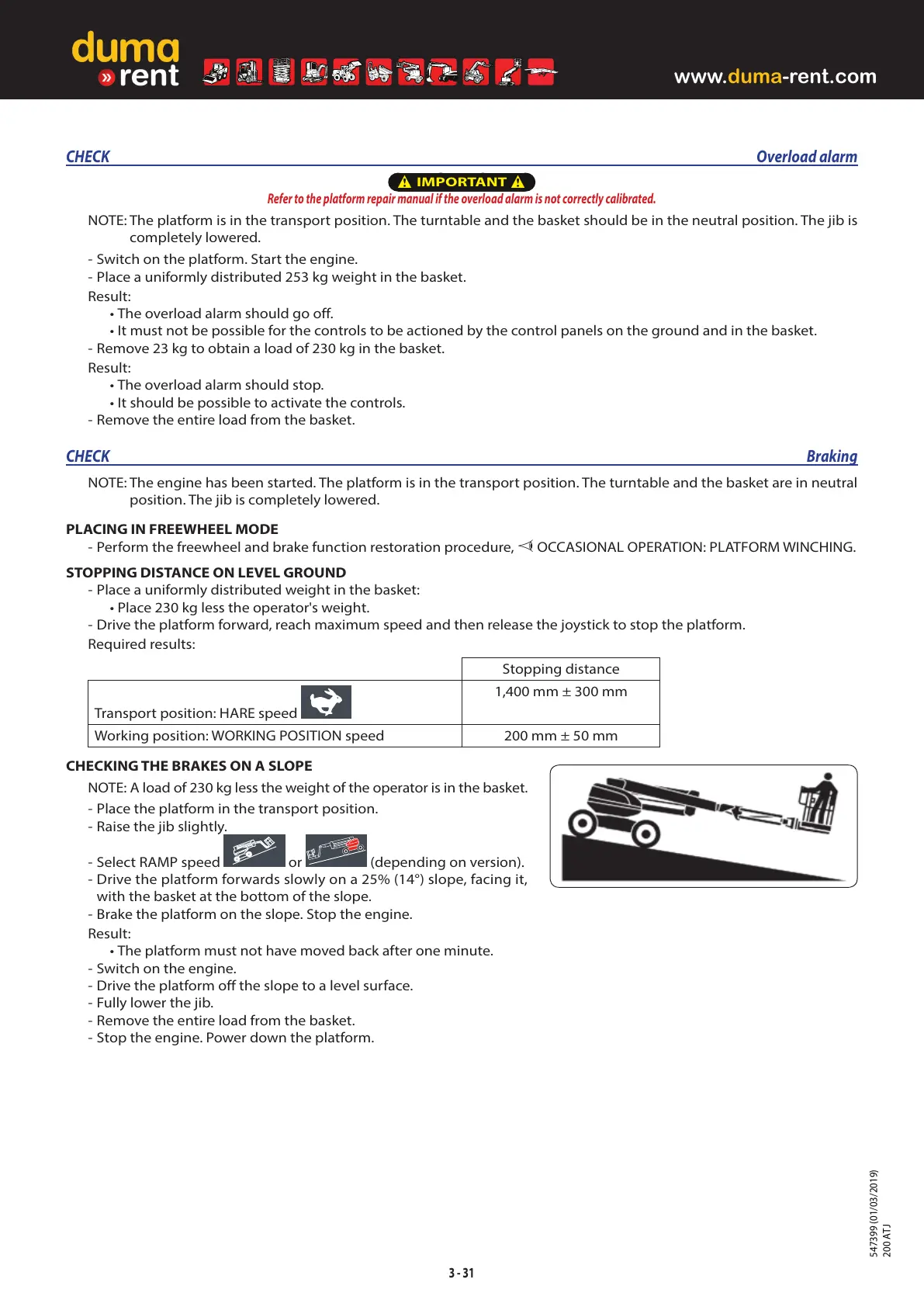

CHECKING THE BRAKES ON A SLOPE

NOTE: A load of 230kg less the weight of the operator is in the basket.

- Place the platform in the transport position.

- Raise the jib slightly.

- Select RAMP speed

or (depending on version).

- Drive the platform forwards slowly on a 25% (14°) slope, facing it,

with the basket at the bottom of the slope.

- Brake the platform on the slope. Stop the engine.

Result:

• The platform must not have moved back after one minute.

- Switch on the engine.

- Drive the platform off the slope to a level surface.

- Fully lower the jib.

- Remove the entire load from the basket.

- Stop the engine. Power down the platform.

Loading...

Loading...