4-25

TMS9000-2 OPERATOR MANUAL OPERATING PROCEDURES

Published 02-21-2019, Control # 611-05

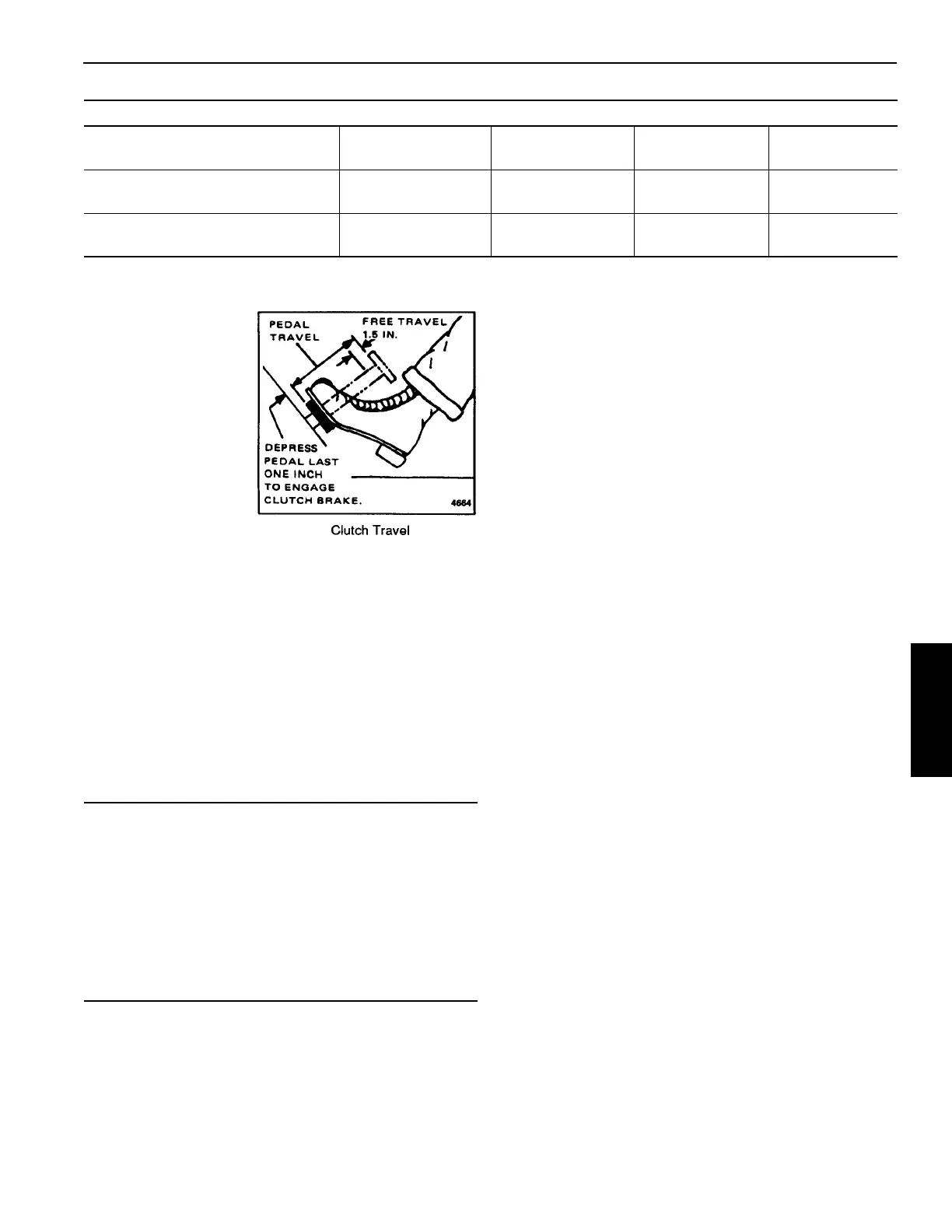

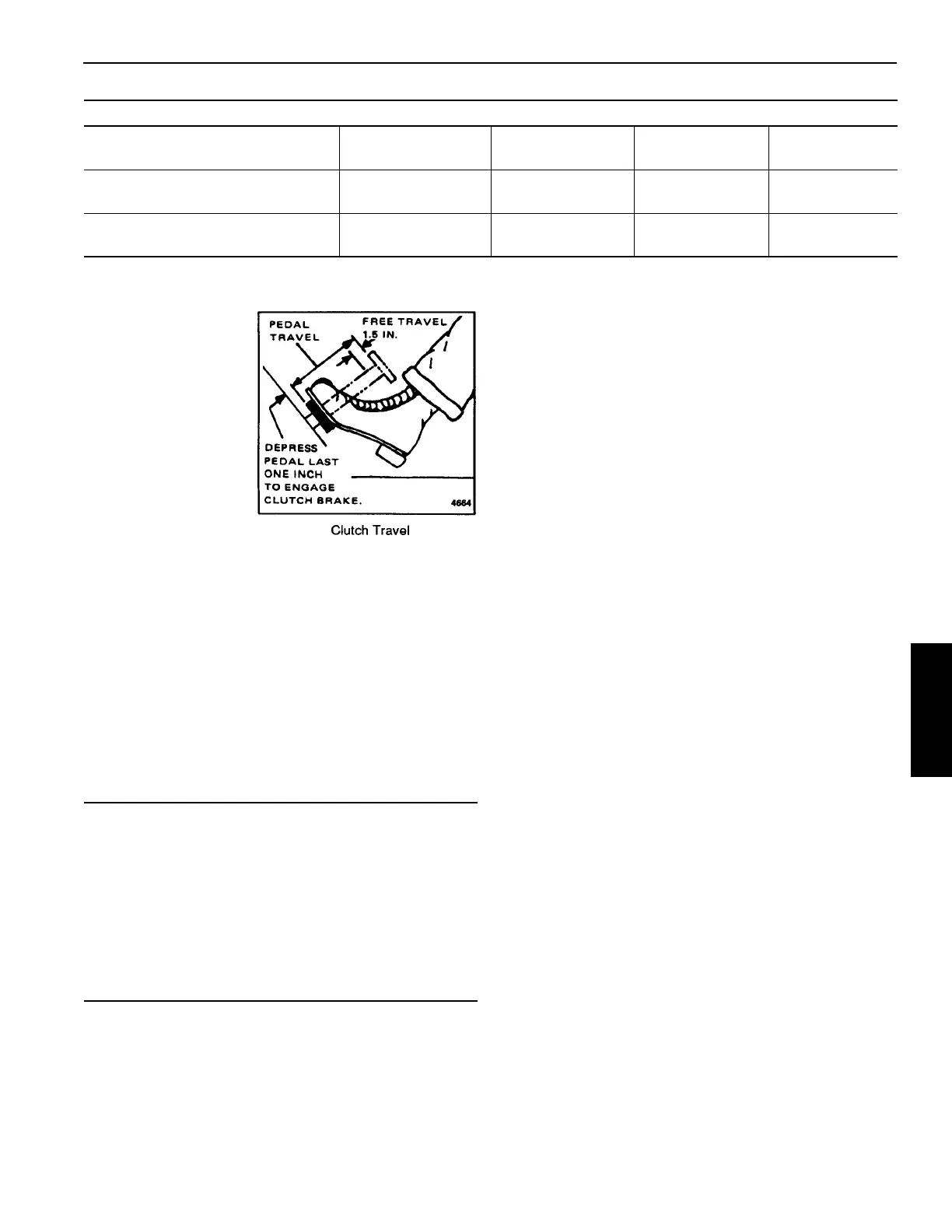

Manual Transmission Clutch Operation

Clutch pedal

adjustment

(Figure 4-18) provides

for approximately 38.1

mm (1.5 in) for free

travel movement of the

pedal after the first free

travel of 12.7 mm (0.5

in) is passed before

engaging the release

bearing fully. It is

important that this free

travel be maintained to

avoid possible

excessive wear on the

bearing and/or clutch slippage. Approximately the last 25

mm (one inch) of downward clutch pedal travel engages the

clutch brake which overcomes the tendency of the clutch to

rotate at high speed when the clutch is disengaged. A slight

but definite resistance to clutch pedal downward movement

will be felt at the last 25 mm (one inch) of travel.

The clutch brake is particularly useful for initial gear

engagement in the lower gears when going uphill, when the

road speed drops off more quickly than the engine speed,

requiring rapid shifts. The clutch brake MUST NOT BE

USED when making a downshift.

Clutch engagement should always be made smoothly while

synchronizing accelerator movement necessary to move the

crane.

Double clutching is a means of bringing the speed of the

transmission gears into synchronization so the shift can be

made without clash. The engine is used to speed up the

countershaft for a downshift and to slow it down for an

upshift. Double clutching operation is accomplished as

follows.

1. Depress the clutch (do not engage clutch brake) and

shift into neutral.

2. Release clutch pedal and accelerate the engine (when

making downshift) or allow the engine to slow down

(when upshifting) until engine speed approximately

corresponds to road speed of the gear ratio selected.

3. Depress the clutch pedal (do not engage clutch brake)

and shift into gear.

4. Release the clutch pedal. Always use the double

clutching technique.

NOTE: Never allow your foot to ride the clutch pedal when

the clutch is engaged. This causes premature

release bearing failure and short clutch disc life.

Shifting Gears

Next to concern for safety, good shifting habits are probably

the most important capability a driver can have. Knowing

how and when to shift can return savings in trip time and

operating expense.

In the early stage of moving the crane, keep the engine

speed down to the actual power requirement but anticipate

the next shift demand and do not cause the engine to labor

with the next shift. Start the crane in the lowest gear

necessary and with the first few shifts, develop only the

engine speed (RPM) needed to get rolling. Then as you

upshift, increase crane speed in each gear with a

progressive increase in engine speed. It should seldom be

necessary to go to governed engine speed in the lower gears

except in a peak load situation, such as starting up a grade.

The biggest task when climbing a grade generally will be

maintaining a reasonable rate of speed. When possible,

preplan the climb and probable shift requirements according

to traffic conditions and grade to be climbed.

When approaching a hill, gradually move the throttle all the

way down, if necessary, to maintain governed engine speed

(RPM) and remain at full throttle as the crane starts up the

grade. If there is sufficient power to maintain satisfactory

road speed without the engine laboring, remain in that gear

SUB: Main Hoist Cable (843’ of K-

100 Rope)

-176.91 (-69.65) -401 (-884) 126 (278) -527 (-1162)

SUB: Aux Hoist Cable (604’ of K-100

Rope)

-271.91 (-107.05) -286 (-631) 138 (305) -425 (-936)

SUB: Automated Manual

Transmission

562.31 (221.38) 34 (75) 34 (75) 0 (0)

Axle Weight Distribution Table

CAUTION

Never fully depress the clutch pedal before the

transmission is put in neutral. If the clutch brake is applied

with the transmission still in gear, a reverse load will be put

on the gears making it difficult to get the transmission out

of gear. At the same time, it will have the effect of trying to

stop or decelerate the crane with the clutch brake, with

resultant rapid wear and generation of excessive heat,

necessitating frequent replacement of the brake friction

discs.

Loading...

Loading...