4-37

TMS9000-2 OPERATOR MANUAL OPERATING PROCEDURES

Published 02-21-2019, Control # 611-05

I

NOTE: It may be necessary to jog the outrigger extension/

retraction switch slightly to ensure proper pin

engagement.

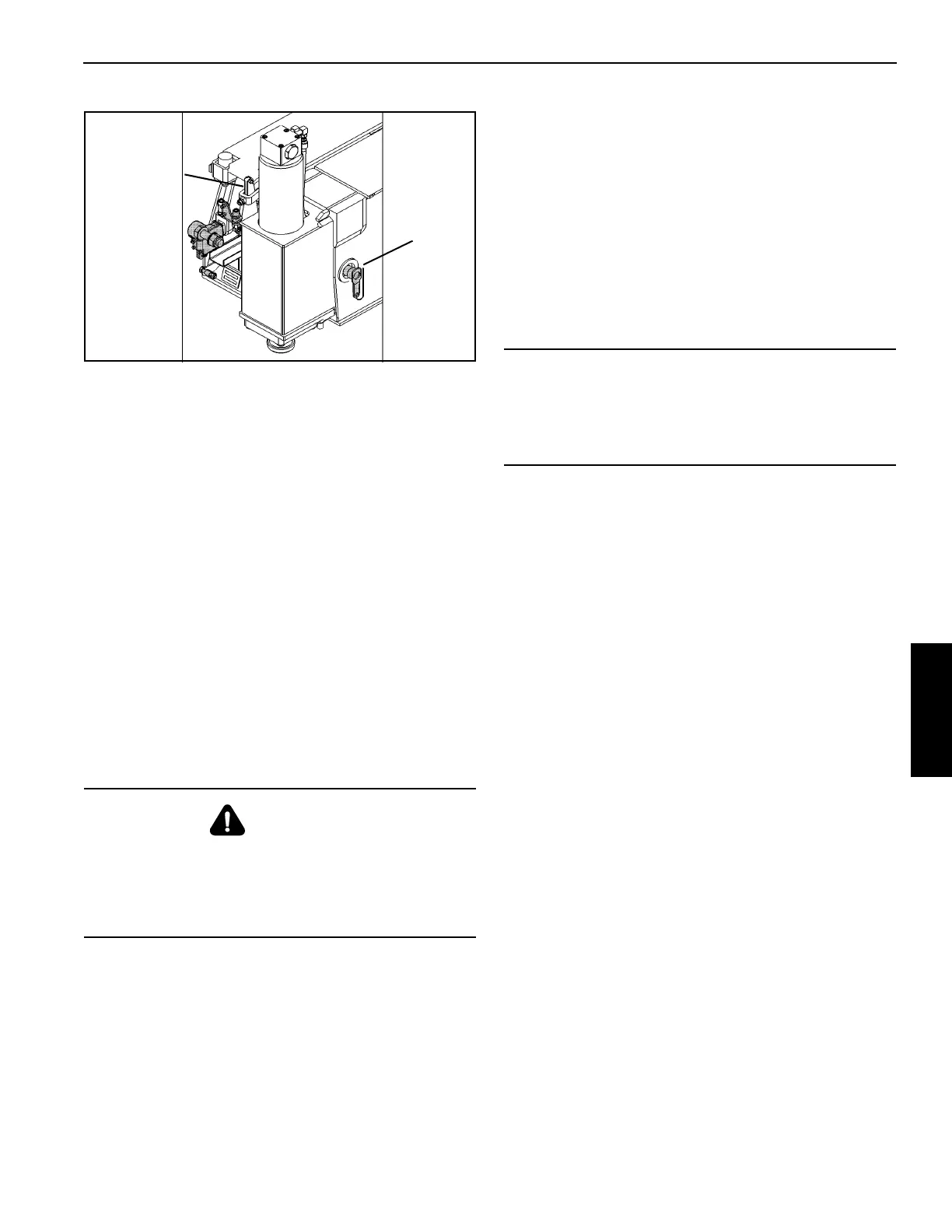

With the outriggers fully retracted, disengage the locking

stirrup from its stowed position. Slowly extend the outriggers

to the partial extend position, until the outer extension beam

and inner extension beam holes align. Partial extend

positions can be located at 57 or 79 percent position. Extend

beam until the locking pin holes aligns with the holes on the

extension beam, refer to Figure 4-29. Remove locking pin

from stowage bracket located next to the frame of the

outrigger box. Insert locking pin into Partial/Mid Extension

locking holes and rotate pin until retention pin aligns with slot

in locking hole of outrigger beam. Swing handle on the lock

pin until lug is pointing downward in order to retain pin in a

secured position. If the pin will not slip into the hole freely,

slowly extend or retract the outrigger beam, allowing the

locking pin to engage into the holes.

Stowing the Center Front Jack

1. Position the Center Front Jack control switch to

ACTIVATE and position the outrigger extension/

retraction switch to RETRACT.

2. Retract the center front jack until the jack is fully

retracted.

CRANE OPERATION

Before operating the crane

NOTE: This procedure only applies to working with a

rigged truck crane (supported and rigged with

counterweight). If the truck crane is not yet rigged

refer to Set-up and Installation, page 6-1.

Perform the inspections as outlined in Pre-Starting Checks,

page 4-2.

1. Inspect the truck crane, looking out in particular for any

leaking fluids (oil, fuel or water).

2. Adjust crane cab seat and front panel, refer to Adjusting

the crane cab seat and front control panel, page 4-38.

3. Switch on the cameras for the operation of the crane,

refer to Cameras for crane operation, page 6-41.

4. Adjust the slewable spotlights if necessary, refer to

Using the slewable spotlights, page 4-86.

5. Start the engine for crane operation.

Check the operation of all crane functions. If any

malfunctions are noted, do not use the crane until the issues

are corrected.

6. Check the position of the hoist ropes, refer to Checking

the position of the hoist ropes, page 4-38.

7. Compare current rigging mode to display on RCL – enter

current rigging mode, if necessary, refer to Enter rigging

mode, page 4-44.

8. Compare current reeving of hoist used against the

display on the RCL – enter current reeving, if necessary,

refer to Entering the reeving, page 4-48.

9. Check telescoping, refer to Inspections prior to starting

operations, page 4-64.

10. Switch off the swing gear if working at 0° or 180°

positions – symbol (1, Figure 4-30) red, refer to

Switching off the swing gear, page 4-83.

11. Switch off houselock (if fitted) for other working positions

– symbol (2) is red, refer to Switching off the 360° lock,

page 4-41.

CAUTION

Never operate the center front jack unless the boom is

retracted and in the boom rest position. Always retract the

center front jack before retracting the main jacks and

outriggers. The center front jack is a vital factor in the

stability of the crane.

Locking

Stirrup

9064-2

FIGURE 4-29

Locking

Pin

CAUTION

Environmental hazard!

Fluid spills can result in environmental damage.

Immediately repair all oil, fuel and coolant leaks detected

during inspection.

Loading...

Loading...