LUBRICATION TMS9000-2 OPERATOR MANUAL

5-8

Published 02-21-2019, Control # 611-05

11.Check fluid level using sight gauge on the side of the tank

with boom retracted and in boom rest and all outrigger

cylinders retracted.

12.Engine shall be running during lubrication to ensure equal

distribution of grease.

13.Clean magnetic drain plug when changing lubricant.

14.Service by whichever interval occurs first.

15.Air conditioner - refer to applicable air conditioner

manual.

16.See operator's manual when ambient temperatures are

expected between +4°C (+40°F) and -62°C (-80°F).

17.Generously coat the wheel pilot or hub pads with

lubricant. Do not lubricate the face of the wheel or the hub.

18.Apply lubricant during assembly and reapply lubricant

whenever wheels are removed for service.

19.Clean coolant strainer after first 100 hours of use and at

2000 hrs/1 yr intervals thereafter.

20.Replace air cleaner element when indicator shows red

(25" H2O).

21.Change filter at first 200 hours. thereafter, at normal

intervals. Drain with oil temperature at 65°C - 95°C (150°F -

200°F).

22.Change filter when changing gear oil.

23.Drain water trap every ten hours or daily.

24.QSM T3 engine can also use CJ-4 oil when fueled with

ultra low sulfur diesel (less than 15ppm).

25.Only use on ISX12 engine machines.

26.Service hours:

a. 500 (0-55 ppm sulfur fuel)

b. 400 (500-5000 ppm sulfur fuel)

c. 250 (<5000 ppm sulfur fuel. Not recommended.)

27.Extend boom for access through holes.

28.Lubricate more frequently than interval indicated in table

if environmental conditions and/or operating conditions

necessitate.

29.Access through hole in base section.

30.Access through hole in tele 1 section.

31.Access through hole in tele 2 section.

32.Access through hole in tele 3 section.

33.Access through hole in tele 4 section.

34.Refer to spec 6829103618 for the lubrication procedure

and the service manual for detailed service interval related

information.

35.Fill turntable gearbox until oil level is at middle to top of

sight gauge.

36.Fill turntable gear brake until oil level is at top of sight

gauge.

37.Fill grease container until grease level is at the “max”

mark.

38.Brush lubricant on top and bottom wear pads of outrigger

beams.

39. CAUTION: DEF is corrosive to certain metals and paint

and should be washed off with mild soap and water if spilled.

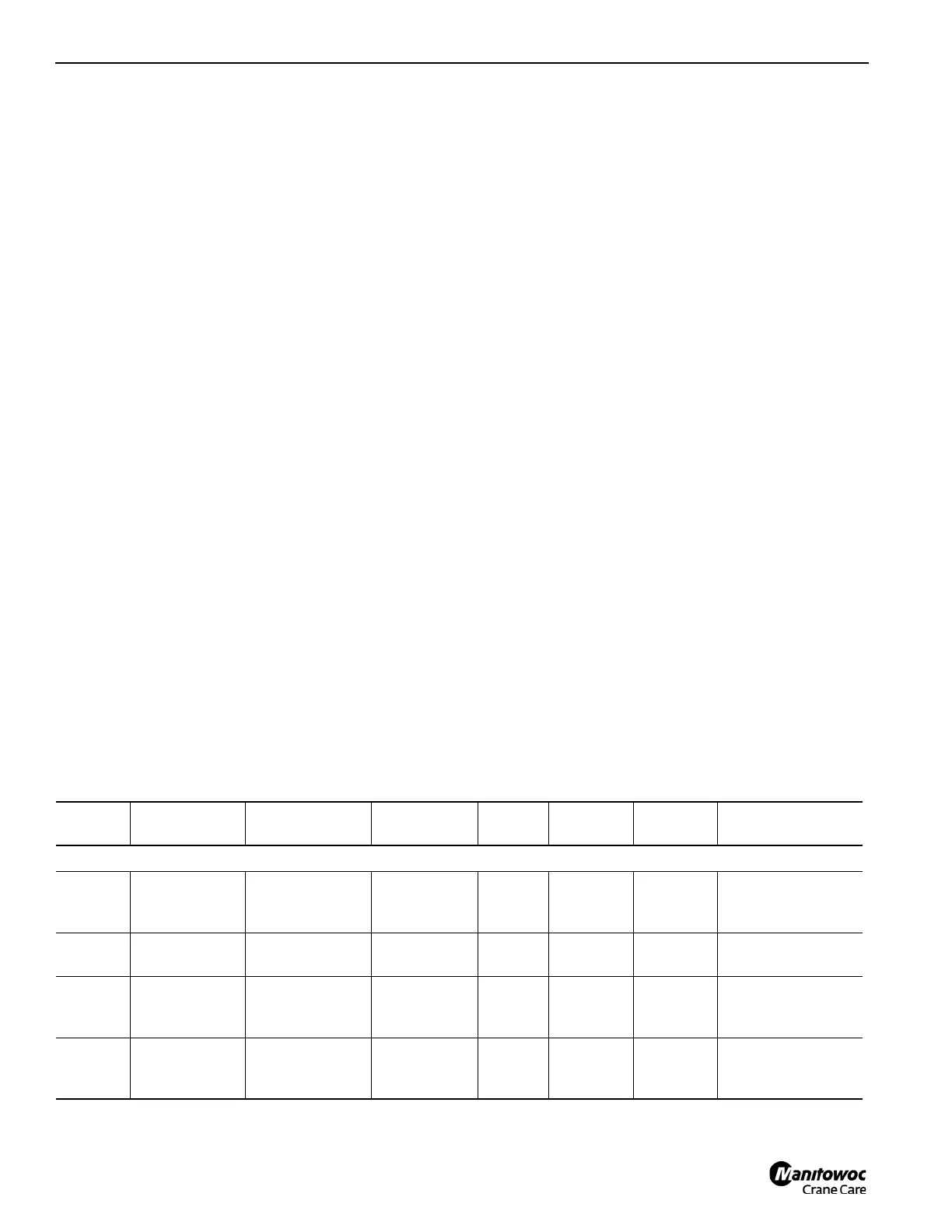

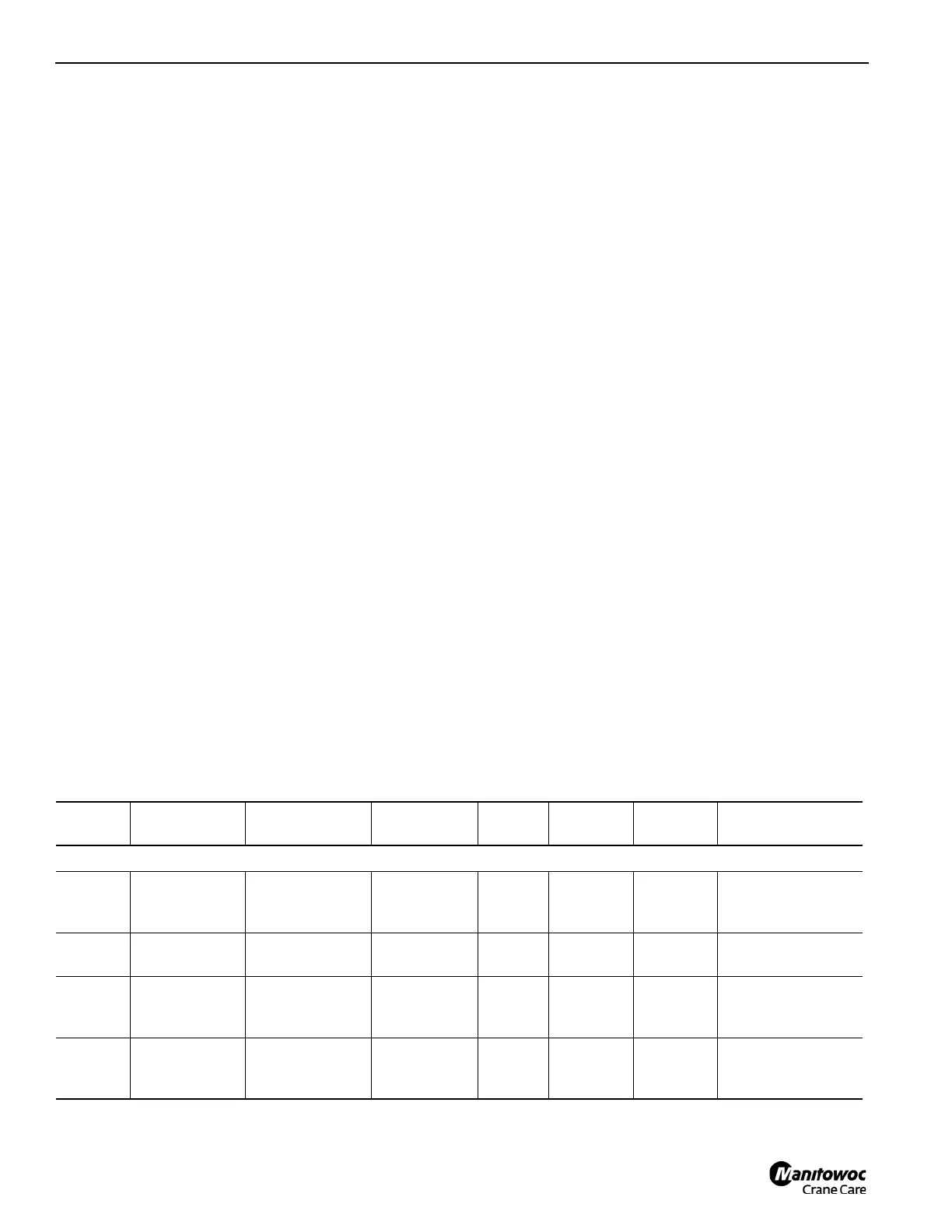

The following describes the lubrication points and gives the

lube type, lube interval, lube amount and application of each.

Each lubrication point is numbered, and this number

corresponds to the index number shown in the following

figures.

Drivetrain Lubrication.

ITEM

NUMBER

LOCATION

NAME

APPROXIMATE

CAPACITY

LUBE SPEC NOTES

SERVICE

POINTS

SERVICE SERVICE HOURS

DRIVETRAIN

1

ENGINE

CRANKCASE

ISX

--------------- 6829104182 2, 14 1

CHECK &

FILL

10 HRS/DAILY

WITH FILTER 42.8 L (11.3 GAL) 6829104182 2 1

DRAIN &

FILL

750 HRS

2a

ENGINE

COOLING

SYSTEM

-------------- 6829101130 4, 9, 14 1

CHECK

&FILL

10 HRS/DAILY

ENGINE

COOLING

SYSTEM - ISX

74.6 L (19.7 GAL) 6829101130 1

DRAIN &

FILL

SEE SERVICE

MANUAL

Loading...

Loading...