155

5. PARAMETERS

5.3 Speed control under PM motor control

3

4

5

5

5

6

7

8

9

10

5.3.2 Performing high-accuracy, fast-response control (gain

adjustment for PM motor control)

Manual gain adjustment is useful for achieving optimum machine performance or improving unfavorable conditions, such as

vibration and acoustic noise during operation with high load inertia or gear backlash.

Adjusting the speed control gain manually

• The speed control gain can be adjusted for the conditions such as abnormal machine vibration, acoustic noise, slow

response, and overshoot.

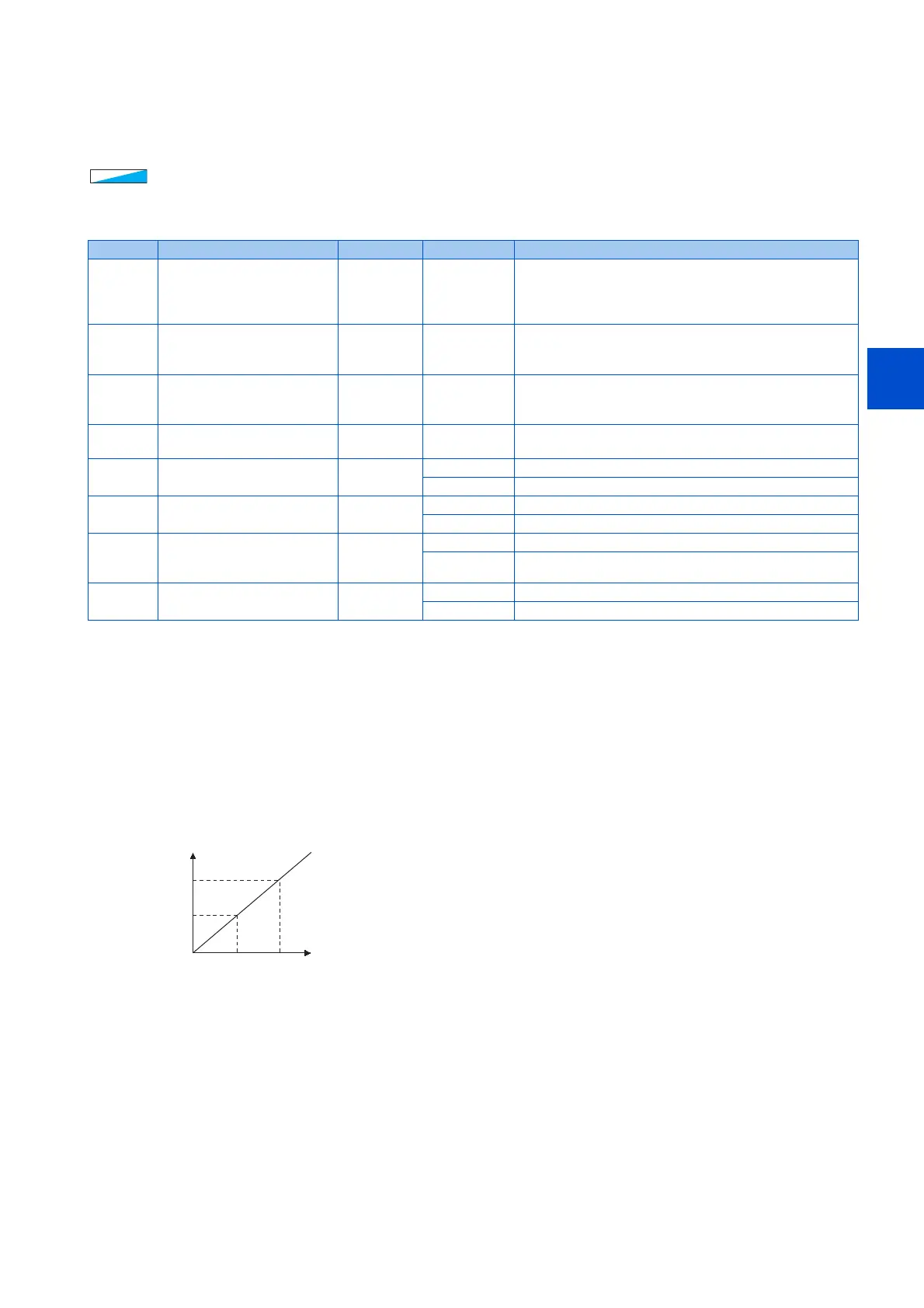

• Pr.820 Speed control P gain 1="25% (initial value)" is equivalent to 50 rad/s (speed response of a single motor).

(Equivalent to the half the rad/s value with the FR-F860-01080 or higher.) Setting this parameter higher speeds up the

response, but setting this too high causes vibration and acoustic noise.

• Setting Pr.821 Speed control integral time 1 lower shortens the return time to the original speed during speed fluctuation,

but setting it too low causes overshoot.

*1 The value in parentheses is applicable with the FR-F860-01080 or higher.

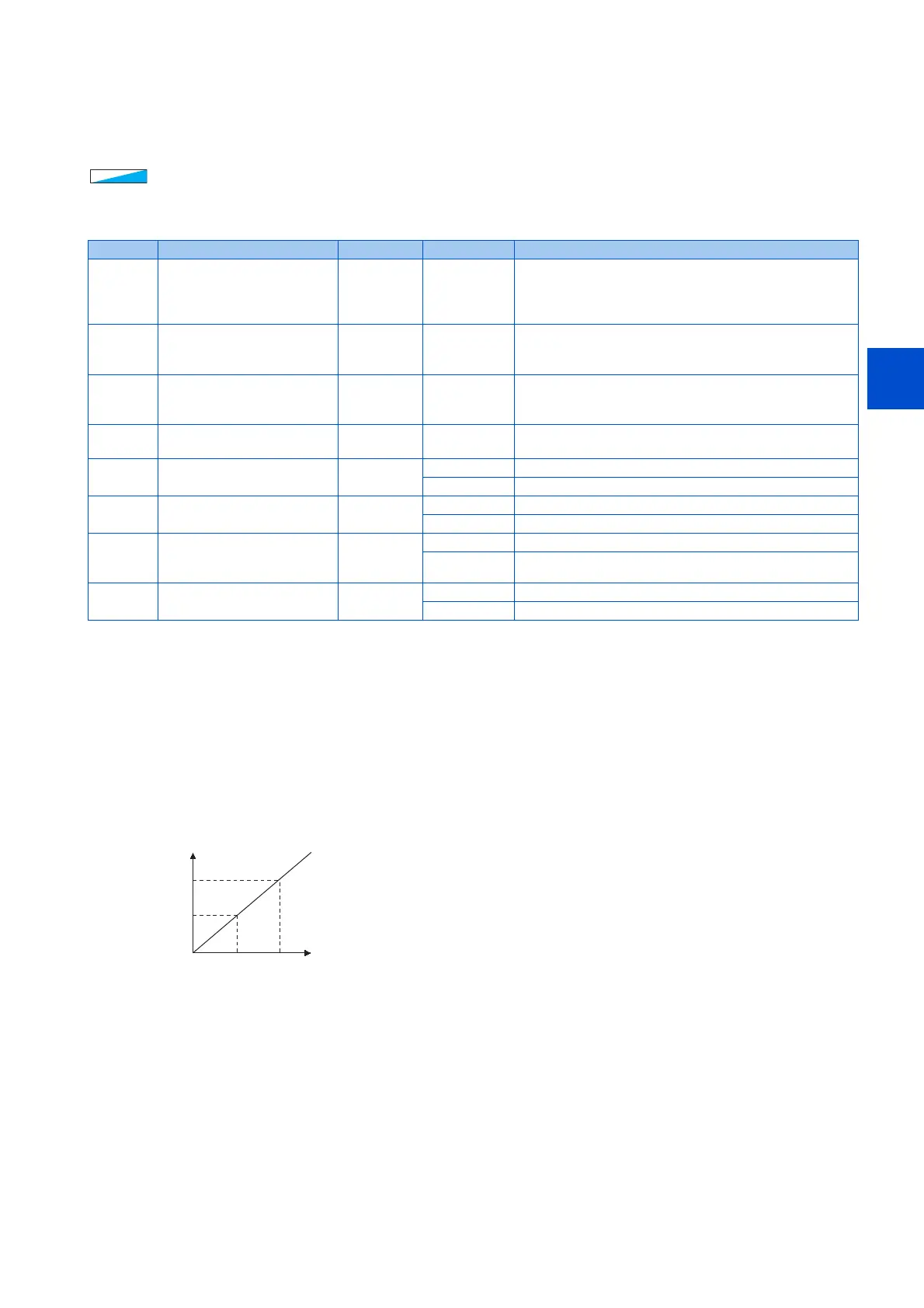

Pr. Name Initial value Setting range Description

820

G211

Speed control P gain 1 25% 0 to 1000% The proportional gain during speed control is set. (Setting this

parameter higher improves the trackability for speed

command changes. It also reduces the speed fluctuation

caused by external disturbance.)

821

G212

Speed control integral time 1 0.333 s 0 to 20 s The integral time during speed control is set. (Setting this

parameter lower shortens the return time to the original speed

when the speed fluctuates due to external disturbance.)

824

G213

Torque control P gain 1

(current loop proportional

gain)

50% 0 to 500% The proportional gain of the current controller is set.

825

G214

Torque control integral time

1 (current loop integral time)

40 ms 0 to 500 ms The integral time of the current controller is set.

830

G311

Speed control P gain 2 9999 0 to 1000% Second function of Pr.820 (valid when RT signal is ON)

9999 The Pr.820 setting is applied to the operation.

831

G312

Speed control integral time 2 9999 0 to 20 s Second function of Pr.821 (valid when RT signal is ON)

9999 The Pr.821 setting is applied to the operation.

834

G313

Torque control P gain 2

(current loop proportional

gain)

9999 0 to 500% Second function of Pr.824 (valid when RT signal is ON)

9999 The Pr.824 setting is applied to the operation.

835

G314

Torque control integral time

2 (current loop integral time)

9999 0 to 500 ms Second function of Pr.825 (valid when RT signal is ON)

9999 The Pr.825 setting is applied to the operation.

Pr.820

Setting

100%

25%

(initial value)

Proportional gain

200 (100) rad/s

50 (25) rad/s

∗1

∗1

Loading...

Loading...