7.25

CLUTCHING

DRIVE SYSTEM ADJUSTMENTS

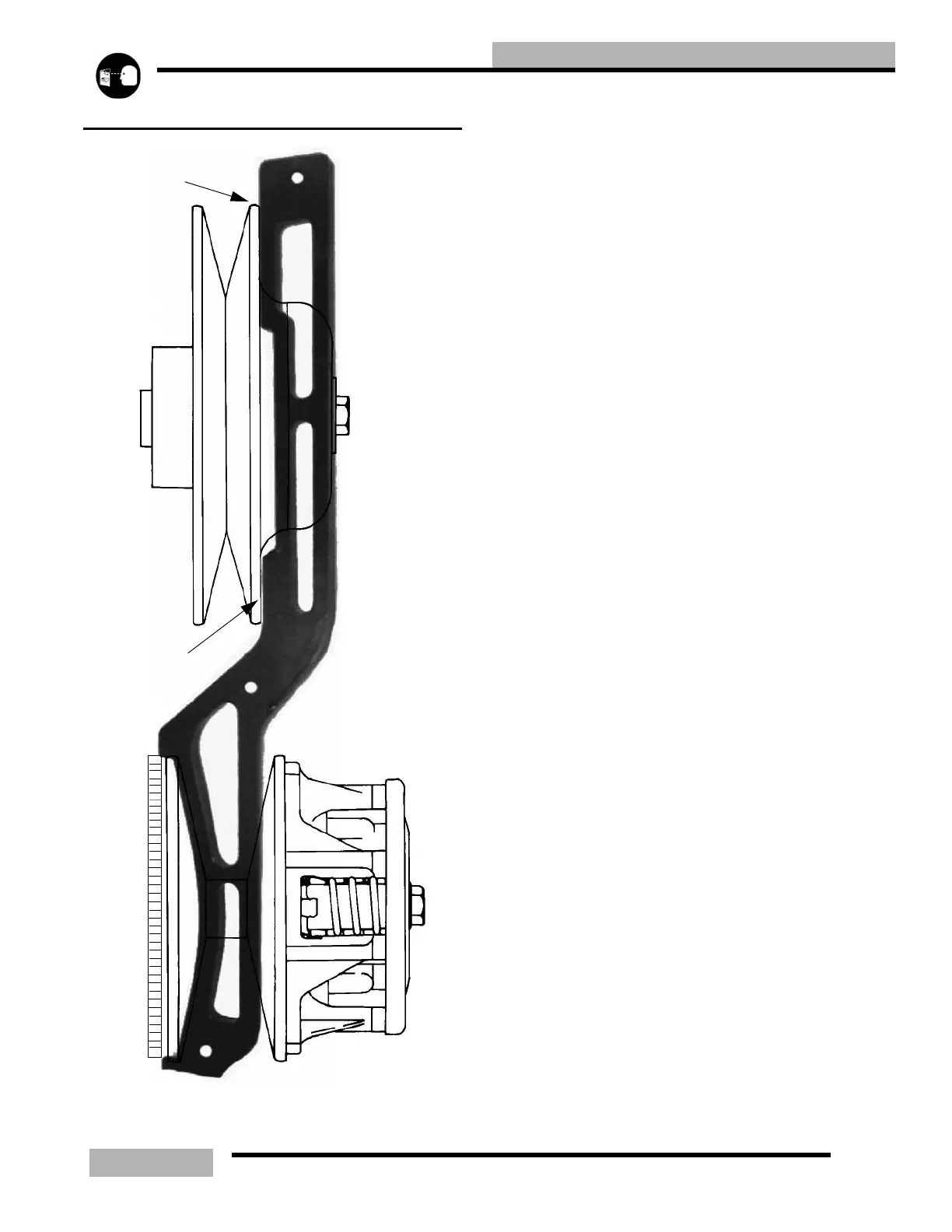

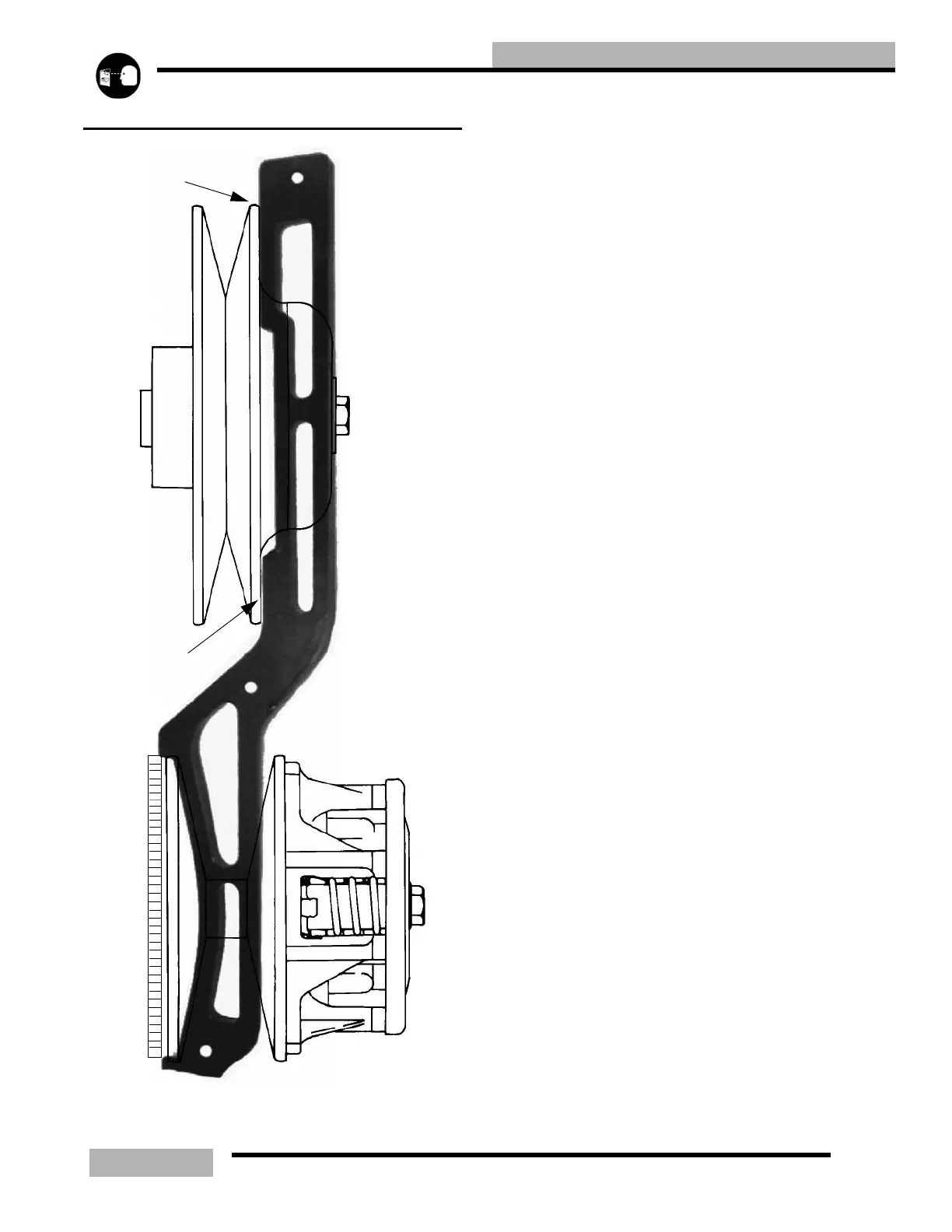

CLUTCH ALIGNMENT

The engine is mounted into the bulk head so that when the

torque of the belt is under power it, will produce clutches that

are aligned.

CLUTCH ALIGNMENT INSPECTION

1. Remove drive belt, See “DRIVE BELT REMOVAL

WITH TEAM CLUTCH” on page 7.5

2. Install alignment tool PN PS-46998.

3. Ideal set up would be that both front and rear portions of

the clutch would be touching. If any gap is present it

should not exceed .060" (3mm) at the rear and .025”

(.63mm).

CLUTCH ALIGNMENT ADJUSTMENT

1. Loosen engine mounting bolts.

2. Adjust the engine torque stop until the clutches are in

proper alignment.

3. Tighten engine mounts securely.

4. Re-check both clutch offset and clutch alignment.

5. Verify proper torque stop adjustment. See “TORQUE

STOP” on page 3.24

CLUTCH OFFSET

Clutch off set is a combination of engine mounting, clutch

sheave angles, clutch diameters and casting thickness. These

are built into the alignment tool PN PS-46998.

OFF SET ADJUSTMENT

1. Determine direction driven clutch needs to be adjusted.

(Refer to Clutch Offset Inspection procedure above).

2. Remove driven clutch retaining bolt, and remove driven

clutch.

3. Add or take out washers on jackshaft between the driven

clutch and jackshaft bearing to achieve proper offset.

4. Most models require the driven clutch to float on the

jackshaft. After adjusting offset, add or remove shim

washers from the retaining bolt to provide a +/- 0.030”

(.75mm) of float on the jackshaft.

0 - .060”

0 - .025”

CLUTCH ALINGMENT TOOL

Loading...

Loading...