3.11

MAINTENANCE

CRANKSHAFT INDEXING

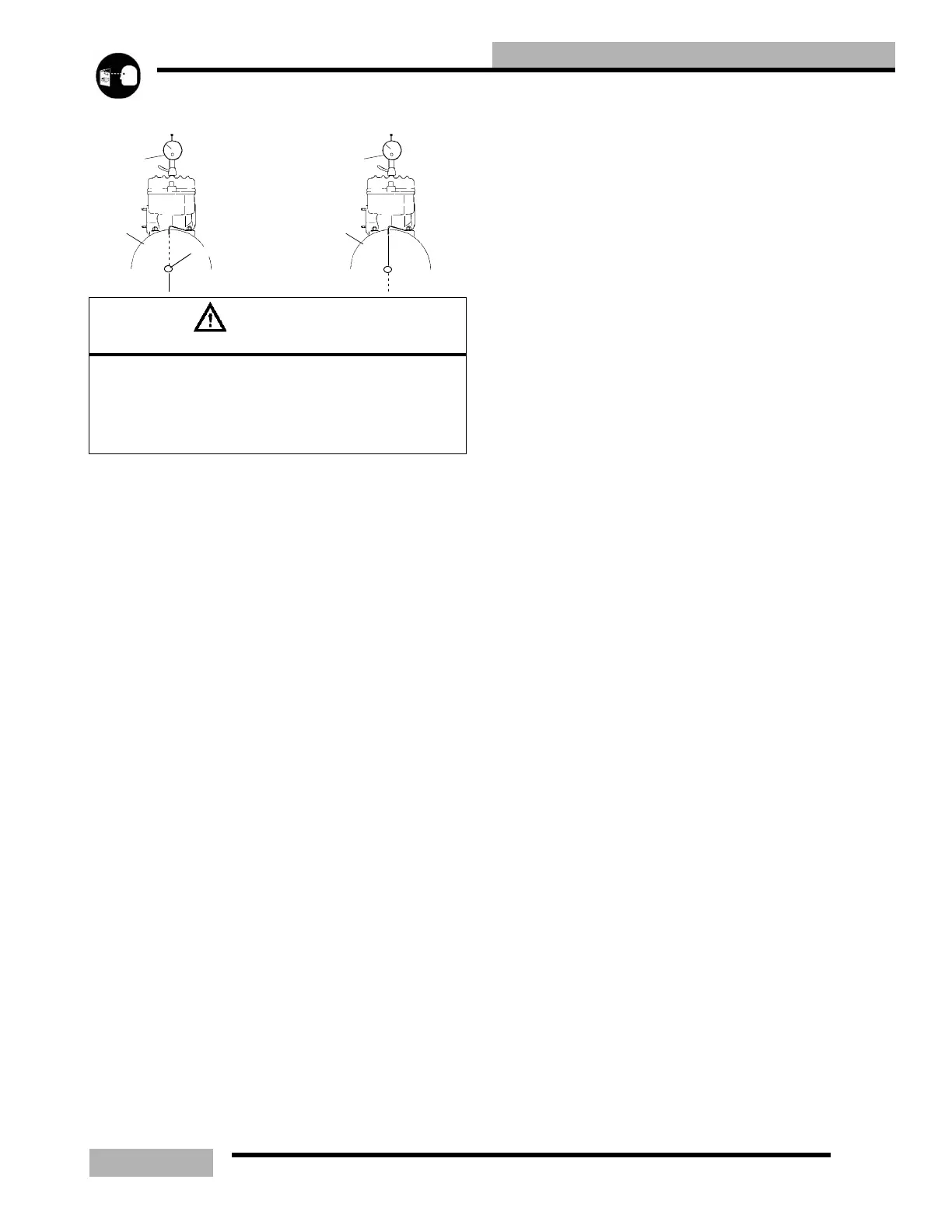

Polaris uses crankshafts that are pressed together. The

connecting rod journal center lines are indexed 180_(twins).

It is sometimes necessary to check multi-cylinder crankshafts

to verify that one cylinder has not been forced out of position

relative to the other cylinder. Some causes for a “out of index”

crankshaft include but ar not limited to the following:

• Hydraulock from water or fuel

• Impact to drive clutch from object or accident

• Abrupt piston or other mechanical failure

• Engine lock-up due to drive belt failure

CHECKING CRANKSHAFT INDEX

1. Remove the drive belt, see DRIVE BELT in Chapter 7.

2. Remove the drive clutch, see “DRIVE CLUTCH

REMOVAL” on page 7.10.

3. Securely fasten a large degree wheel on the flywheel or

PTO end of the crankshaft. Make sure that it is mounted

concentrically with the crankshaft center line.

4. With a section of wire (wire coat hanger), anchor it to a

convenient spot. Bend one end at the outer perimeter of the

degree wheel as shown above.

5. Install a dial indicator into the magneto end cylinder spark

plug hole. The ignition timing is referenced by the

magneto end.

6. Locate TDC as accurately as possible by finding the center

of the point where there is no piston movement note the

”Zero” the dial indicator at this point.

7. Continue to rotate the crankshaft in the normal direction of

rotation until the dial indicator reads .100" (2.54mm) after

top dead center (ATDC).

8. Bend the pointer or move the degree wheel until the

pointer aligns with a 180_ mark on the degree wheel.

9. With the pointer aligned, make sure the degree wheel and

pointer are secured and will not move out of position. Re-

check accuracy of this location a few times. The pointer

should align with the 180_ mark when the dial indicator

reads .100” (2.54mm) ATDC.

NOTE: Do not move the crankshaft, degree wheel or

pointer after the initial setting on the MAG end

cylinder - simply read the wheel and dial indicator.

10. Remove the dial indicator and install in PTO cylinder.

Repeat finding TDC. Note the degree wheel indication

when the dial indicator reads .100" ATDC. It should be

180_ (+/-2_) from the MAG cylinder mark.

Symptoms of an out of index crankshaft can include but are

not limited to the following:

• Difficulty calibrating carburetor (repetitive plug fouling

on one cylinder with no other cause)

• Unexplained piston failure on one cylinder (i.e. severe

detonation, broken ring lands, piston holing)

• Excessive vibration of engine, back firing, etc.

• Rough idle, poor top speed.

CRANKSHAFT TRUING

Lubricate the bearings and clamp the crankshaft securely in

the holding fixture.If truing the crankshaft requires striking

with a hammer, always be sure to re-check previously

straightened areas to verify truing. Refer to the illustrations

below. Use Crankshaft alignment kit PN 2870569.

CAUTION

Disconnect the battery ground cable and ALL spark

plug high tension leads. Ground high tension leads to

the engine. Disconnect lanyard (if equipped) and/or

press the engine stop switch before proceeding with

the following procedure.

Dial Indicator

Degree

Wheel

.100 ATDC

Crankshaft center line

Dial Indicator

Degree

Wheel

.100 ATDC

MAG

PTO

Loading...

Loading...