3.12

MAINTENANCE

NOTE: The Rod Pin position in relation to the dial

indicator tells you what action is required to

straighten the shaft.

CRANKSHAFT RUNOUT INSPECTION

Crankshaft runout can be checked with the engine in the

machine. Using a dial indicator with the crankshaft holding

fixture (PN 2870569) will yield the most accurate results.

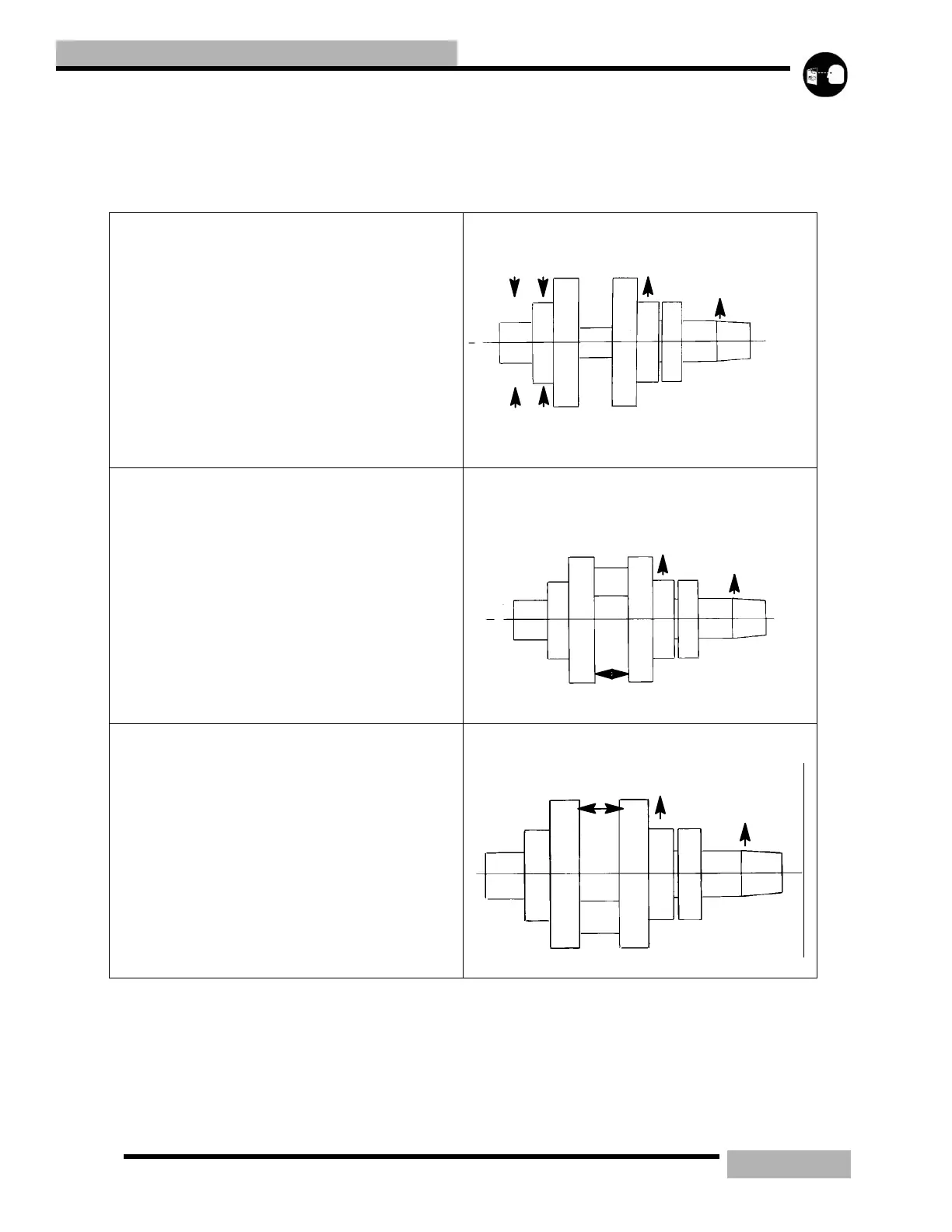

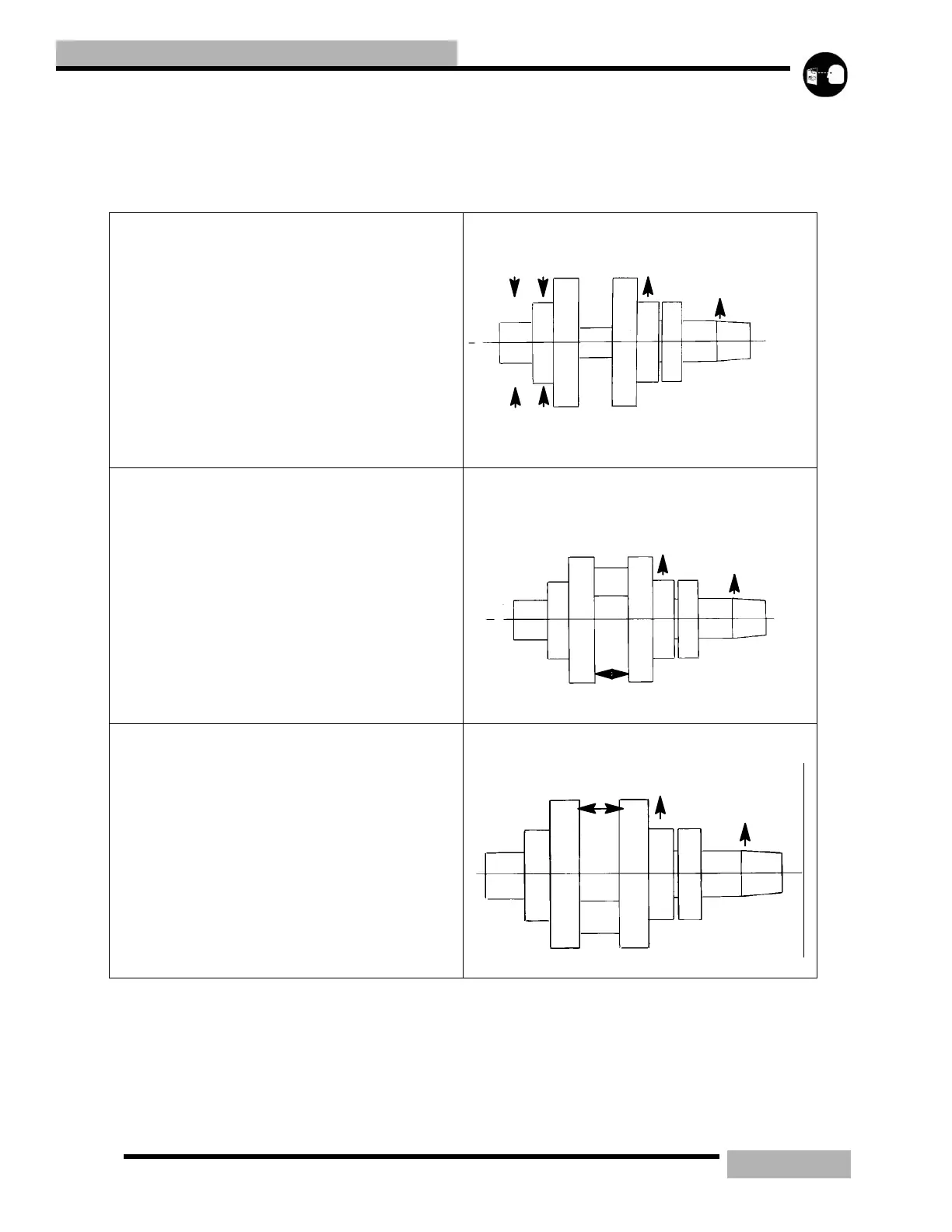

Table 3-3: Truing Examples

To correct a situation like this. Strike the shaft at point

A with a brass hammer.

To correct a situation like the one shown in this.

Squeeze the crankshaft at point A. You will use the

tool from the alignment kit PN 2870569.

If the crank rod pin location is 180_ from the dial

indicator (opposite of above), it will be necessary to

spread the crankshaft at the A position as shown in

illustration 3. When rebuilding and straightening a

crankshaft, straightness is of utmost importance.

Runout must be as close to zero as possible.

A

B

HIGH .004 (.1mm)

HIGH .004 (.1mm)

SUPPORT CRANKSHAFT

AT THESE TWO BEARINGS

AA

HIGH .002 (.05mm)

HIGH .005 (.13mm)

A

HIGH .002 (.05mm)

HIGH .005(.13mm)

A

Loading...

Loading...