502/617

Building Technologies Division User Manual LMS14… CC1U7471en

6 The settings in detail 28.01.2015

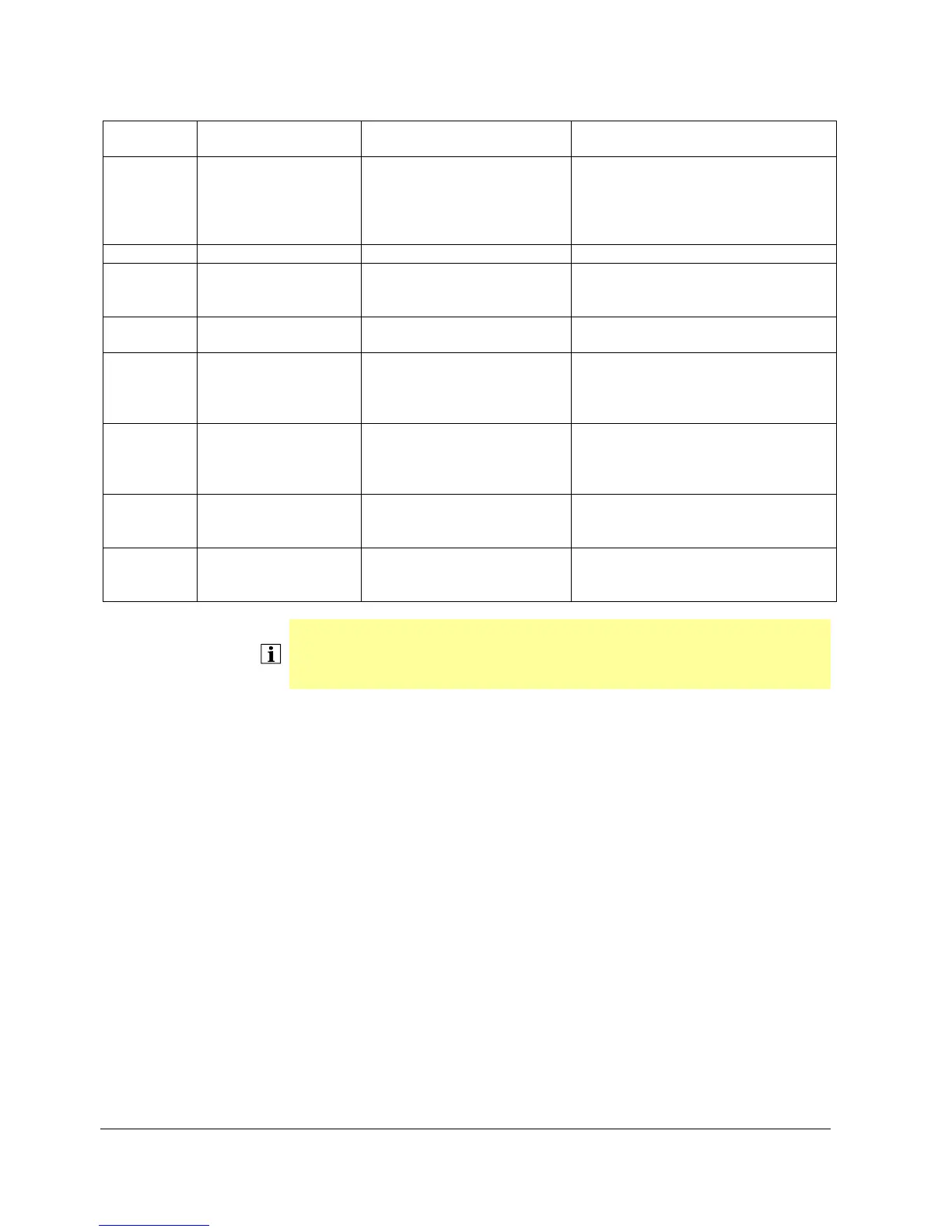

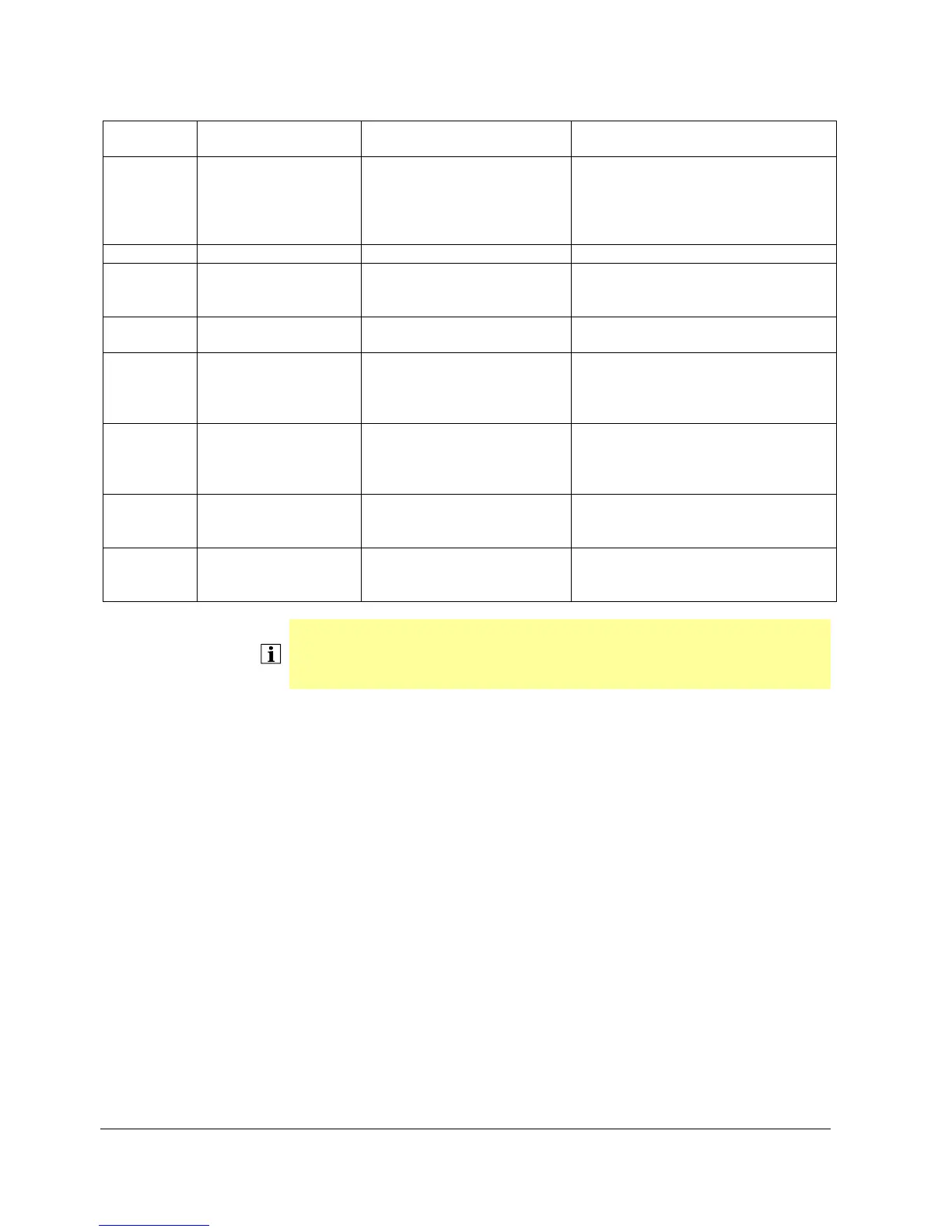

6.28.9 Conditions for the transfer of data between LMS14...

and parameter stick

Line no. Data point name Origin Checks made before data transfer

parameter stick LMS14...

6225 Device family Unique identifier indicating the

LMS14 hardware variant.

This is assigned by Siemens

and cannot be changed by the

OEM

Equality

6234 Boil typ number OEM Freely selectable for OEMs Equality or 0 in data set or LMS14... *

6235 Para set group OEM Depending on classification in

a group when assigning the

parameter set

Equality or 0 in data set or LMS14... *

6236 Para set num OEM Automatically assigned

(incremented)

Equality or 0 in data set or LMS14... *

[4762.1] OnlineDD group

number

Version of online DD, assigned

by Siemens, for OEM

connected with selection of

online DD

Equality or 0 in LMS14...*, provided

online DD is available in the data set

[4689.1] CustomNumb ParaSet Administration of various

OEMs, assigned by Siemens,

for OEM fix

Equality or Siemens standard in

LMS14... (during programming via

parameter stick, Siemens standard is

overwritten by customer no.)

6232 Parameter version Assignment to software version

of LMS14..., assigned by

Siemens, for OEM fix

Equality

6233 Parameter set number = master set no. In setup

manager, assigned by

Siemens, for OEM fix

Equality or 0 in the data set

Note!

If a Siemens standard LMS14... shall be converted to a customized version, a

number of checks must be omitted, or the LMS14... must be identified by entering 0

in the initial parameterization.

OnlineDDGroupNo

In the case of a replacement unit, this number should be 0; otherwise, only online DDs

can be transferred from the same group.

ParaSatzNr

If the data set has a parameter set number entered, this number must accord with the

number in the LMS14... However, most customized versions have a parameter set

number which differs from Siemens’ parameter set number. In that case, a 0 can be

entered in the data set. This is risky, however, since in that case, no consideration is

given to the basic parameter set when checking. This should only be done in

connection with complete parameter settings. In such a case, the OEM parameter set

number should not be set to 0, thus ensuring that a unit whose parameters have

already been set will not be overwritten.

Here, 2 alternatives are available:

1. The customer prepares its replacement unit with its own basic parameter set

(CAPSY gap hex file) and derives the stick data sets from that basic parameter set.

2. The customer derives its stick data sets from Siemens’ basic data set.

Loading...

Loading...