1: At end of block, the actual value display is in principle the same as the

programmed end point,

irrespective of where the machine actually is (e.g. as a result

of the tool radius compensation). The distance to go is the same as the actual distance

to be traversed. This means that the displayed actual postion has to be the same as

the displayed end position minus the distance to go, irrespective of the actual

machine position. If the block end points are changed by chamfers, radii, contour

definitions, splines or SAR in comparison to the NC programm, then these changes are

reflected in the display as if thay had been programmed. This does not apply to changes

resulting from tool radius compensation or smoothing.

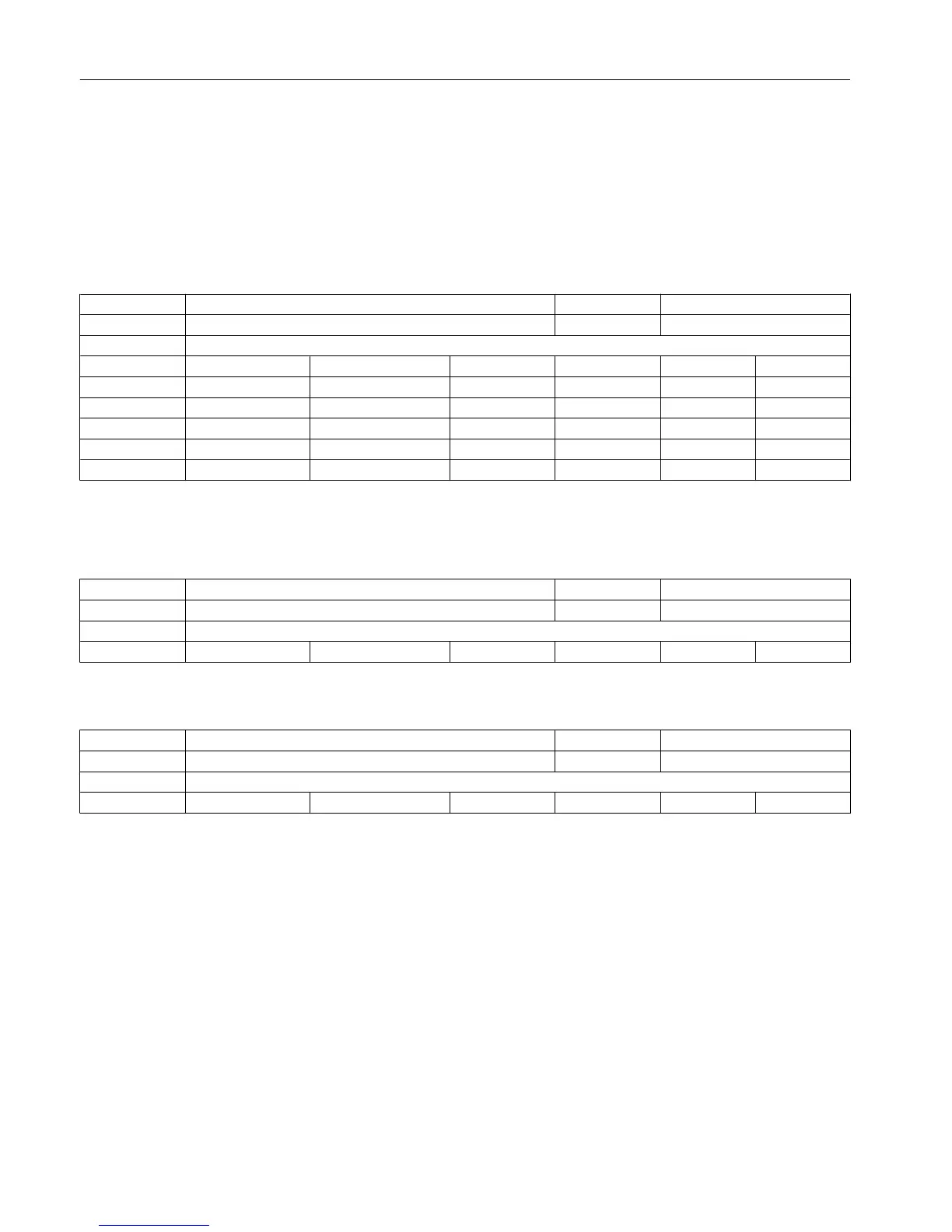

10160 PREP_COM_TASK_CYCLE_RATIO EXP, N01 ECO

- Factor for communication with HMI DWORD PowerOn

-

808d-me42 - 3 1 50 0/0 S

808d-me62 - 3 1 50 0/0 S

808d-te42 - 3 1 50 0/0 S

808d-te62 - 3 1 50 0/0 S

808d-mte40 - 3 1 50 7/1 M

808d-mte60 - 3 1 50 7/1 M

Description: This machine data specifies the division ratio used for activating the communication

task in the non-cyclic time level. This allows the time share of preparation in the

non-cyclic time level to be increased, which reduces block change times. This slows

down external communication (file transfer), especially during program execution

(group-by-group reload).

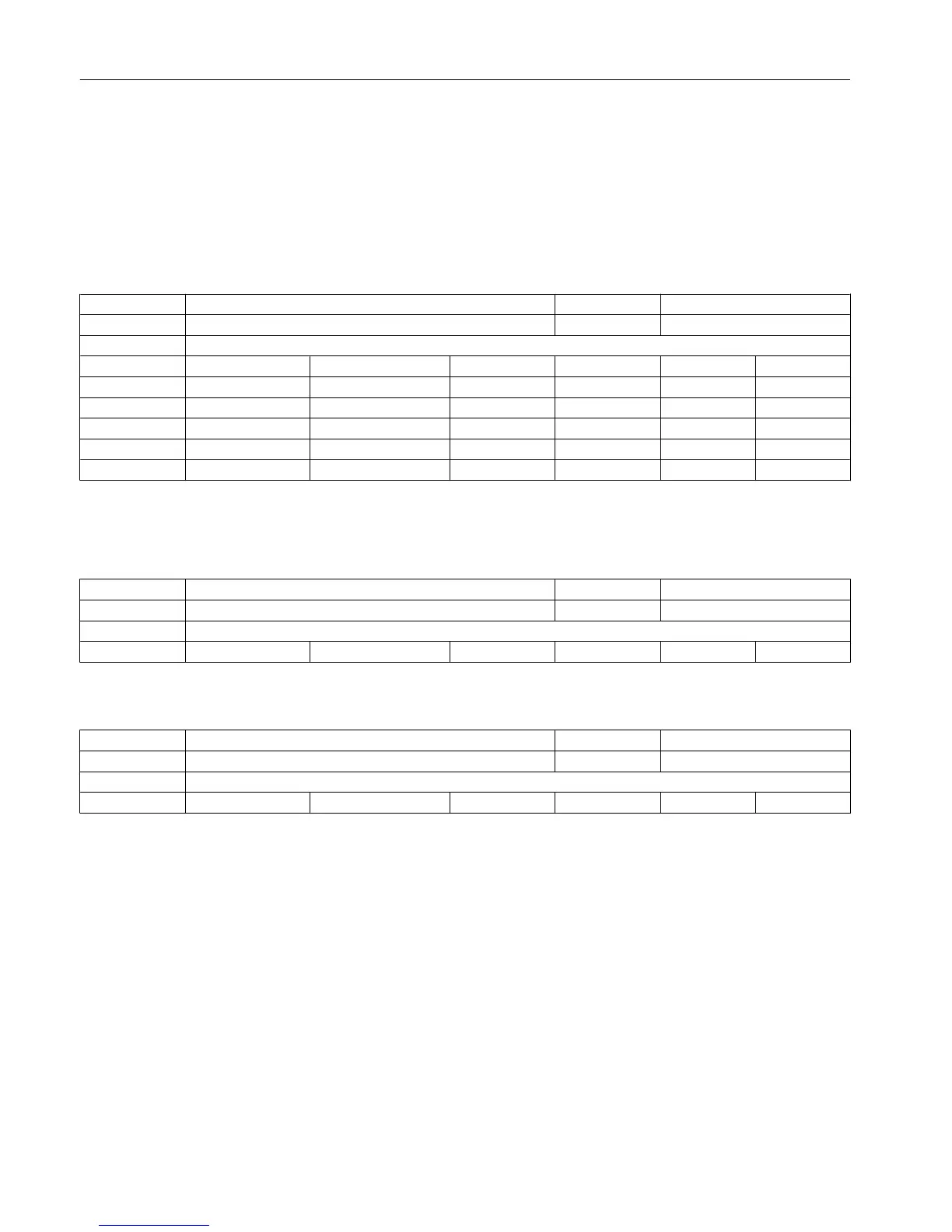

10175 PLC_TASK_RUNTIME_WARNING EXP, N01 ECO

s Prewarning limit for computation time exceeded SW-PLC2xx DOUBLE PowerOn

-

- - 0.000393 0.0 0.000436 1/1 M

Description: The machine data defines the duration for the prewarning of the computation time

exceeded for SW-PLC2xx in seconds. After this time has expired, SW-PLC2xx generates

display alarm 400026 "PLC cycle time has exceeded the alarm threshold".

10192 GEAR_CHANGE_WAIT_TIME N01 S1

s Gear stage change waiting time DOUBLE PowerOn

-

- - 10.0 0.0 1.0e5 1/1 M

Description: External events which trigger reorganization, wait for the end of a gear stage change.

GEAR_CHANGE_WAIT_TIME now determines

the waiting time for the gear stage change. Time

unit in seconds.

When this time expires without the gear stage change having been terminated, the NCK

reacts with an alarm.

Among others, the following events will cause reorganization:

User ASUB

Mode change

Delete distance-to-go

Axis replacement

Activate user data

Machine data

3.2 General machine data

Parameter Manual

36 List Manual, 01/2017

Loading...

Loading...