6-56 ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10)

DTC CONFIRMATION PROCEDURE – Refer to DTC P0130 section.

INSPECTION

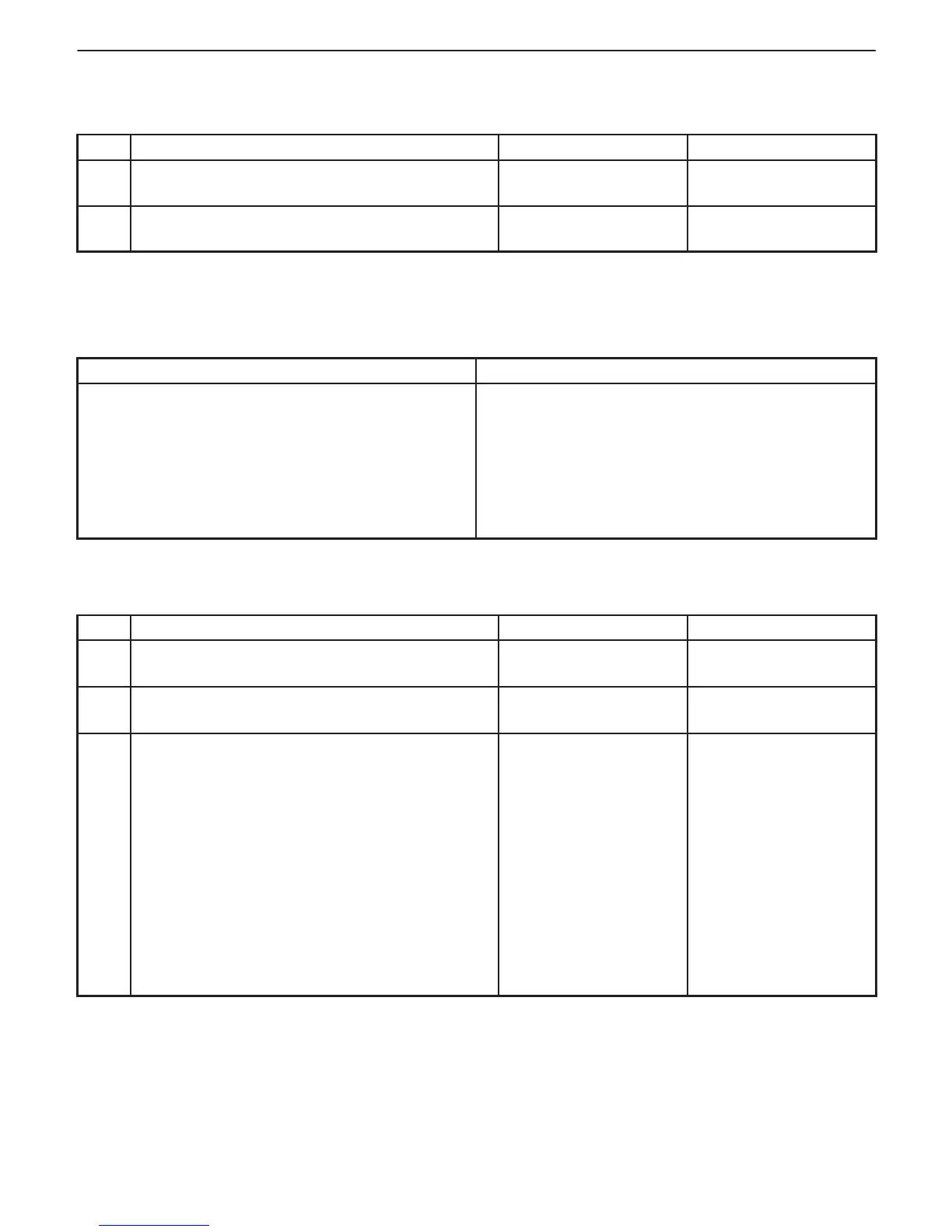

STEP ACTION YES NO

1 Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Is there DTC(s) other than HO2S-1 (DTC P0133)? Go to applicable DTC

Diag. Flow Table.

Replace HO2S-1.

DTC P0134 HEATED OXYGEN SENSOR (HO2S) CIRCUIT NO ACTIVITY

DETECTED (SENSOR-1)

WIRING DIAGRAM/CIRCUIT DESCRIPTION – Refer to DTC P0130 section.

DTC DETECTING CONDITION

POSSIBLE CAUSE

D Engine warmed up.

D While running under other than high load and high

engine speed conditions or at specified idle speed

(engine is in closed loop condition), HO2S-1 output

voltage is high or low continuously.

: 2 driving cycle detection logic, Continuous

monitoring.

D “G” or “R” circuit open or short

D Heated oxygen sensor malfunction

D Fuel system malfunction

D Exhaust gas leakage

DTC CONFIRMATION PROCEDURE – Refer to DTC P0130 section.

INSPECTION

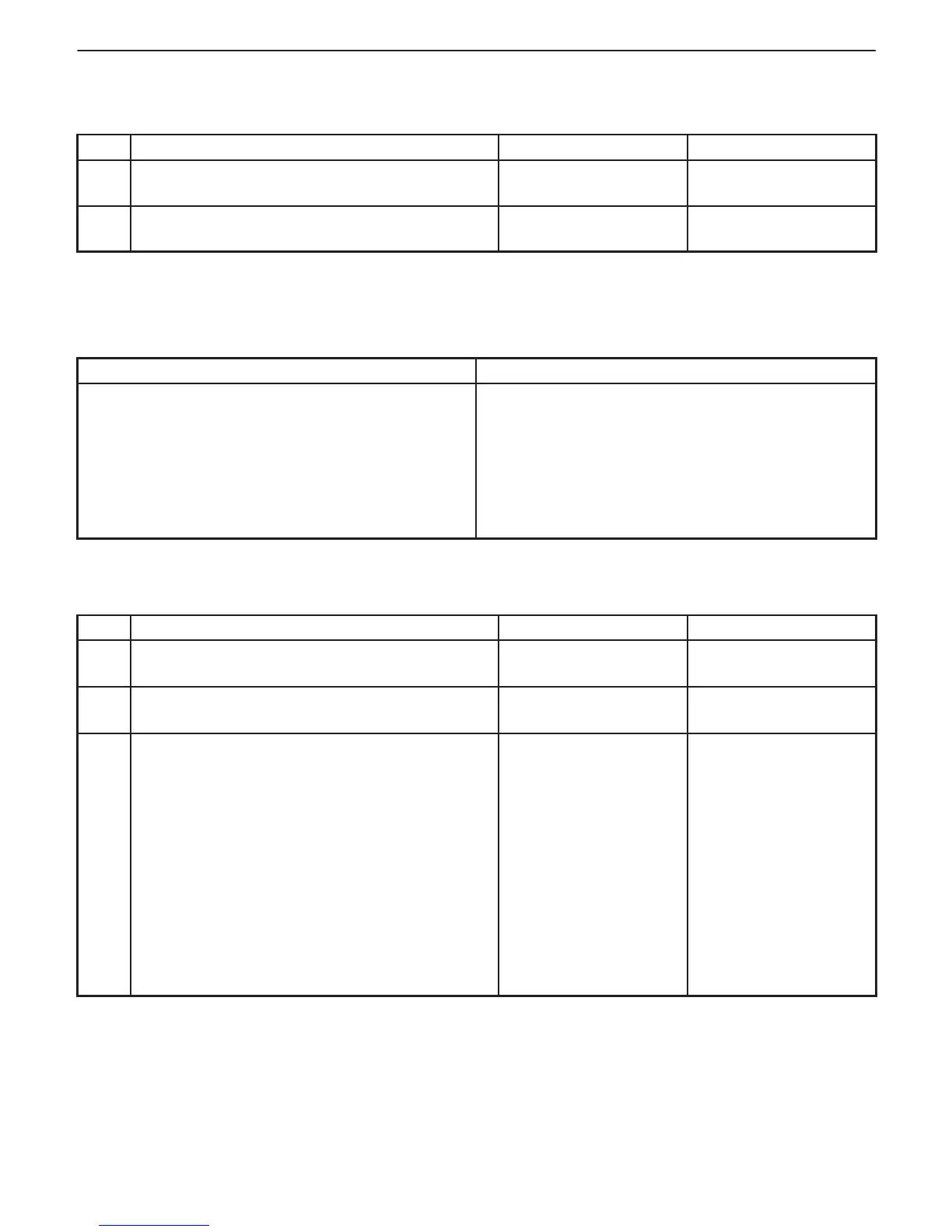

STEP ACTION YES NO

1 Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Is there DTC(s) other than Fuel system

(DTC P0171/P0172) and HO2S-1 (DTC P0134)?

Go to applicable DTC

Diag. Flow Table.

Go to Step 3.

3 Check HO2S-1 and Its Circuit.

1) Connect scan tool to DLC with ignition switch

OFF.

2) Warm up engine to normal operating

temperature and keep it at 2000 r/min. for

60 sec.

3) Repeat racing engine (Repeat depressing

accelerator pedal 5 to 6 times continuously and

take foot off from pedal to enrich and enlean

A/F mixture).

Does HO2S-1 output voltage deflect between

0.3 V and over 0.6 V repeatedly?

Go to DTC P0171 and

P0172 Diag. Flow Table

(Fuel System Check).

Check “R” and “G” wires

for open and short, and

connections for poor

connection. If wires and

connections are OK,

replace HO2S-1.

Loading...

Loading...