6A1-36 ENGINE MECHANICAL (G13B, 1-CAM 16-VALVES ENGINE)

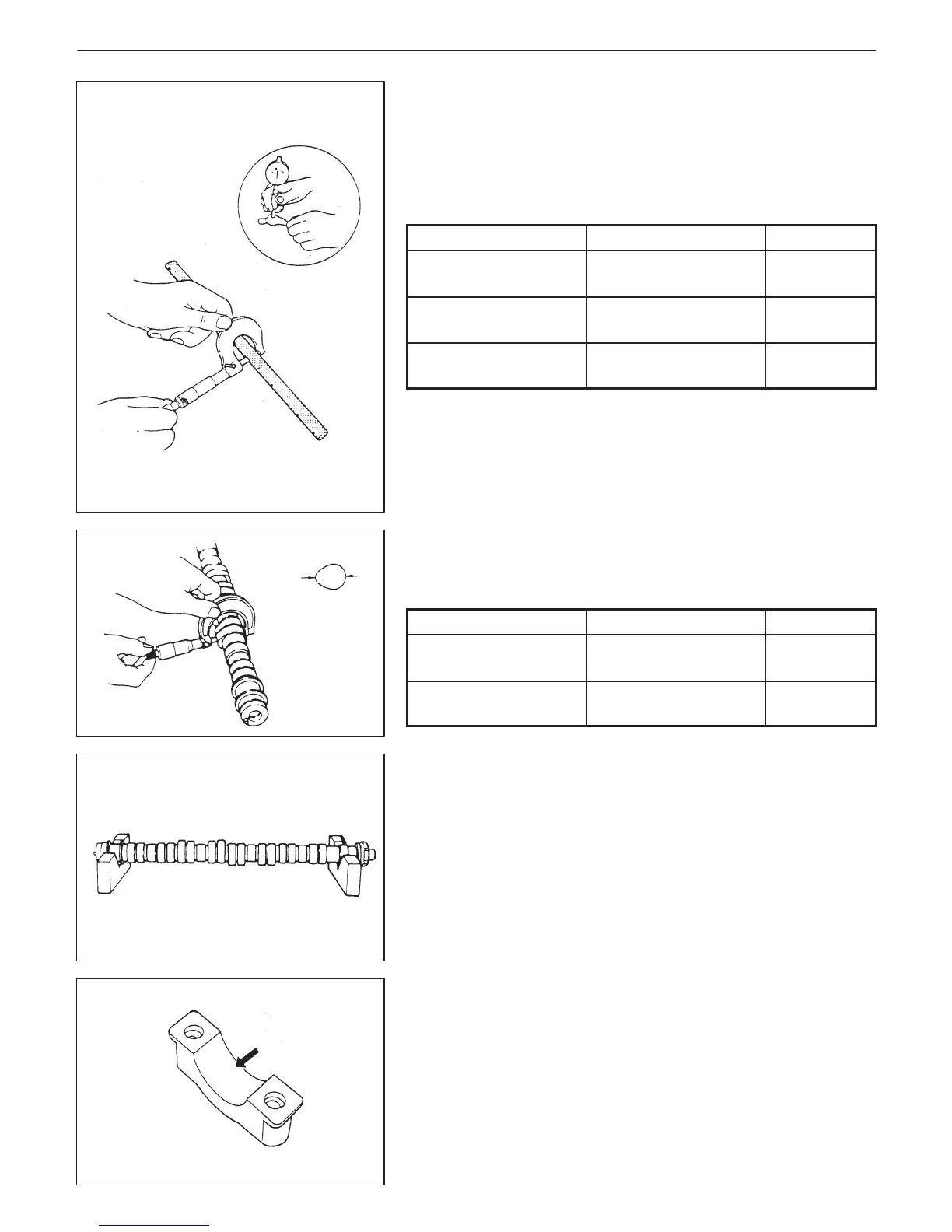

Rocker Arm-to-Rocker Arm Shaft Clearance

Using a micrometer and a bore gauge, measure rocker shaft dia.

and rocker arm l.D.

Difference between two readings is arm-to-shaft clearance on

which a limit is specified.

If limit is exceeded, replace shaft or arm, or both.

Item

Standard Limit

Rocker arm l.D.

15.996 – 16.014 mm

(0.629 – 0.630 in.)

———

Rocker arm shaft dia.

15.969 – 15.984 mm

(0.6287 – 0.6293 in.)

———

Arm-to-shaft clearance

0.012 – 0.045 mm

(0.0005 – 0.0018 in.)

0.09 mm

(0.0035 in.)

Cam Wear

Using a micrometer, measured height of cam. If measured height

is below limit, replace camshaft.

Cam height

Standard Limit

Intake cam

36.184 – 36.344 mm

(1.4246 – 1.4309 in.)

36.084 mm

(1.4206 in.)

Exhaust cam

35.900 – 36.060 mm

(1.4134 – 1.4197 in.)

35.800 mm

(1.4094 in.)

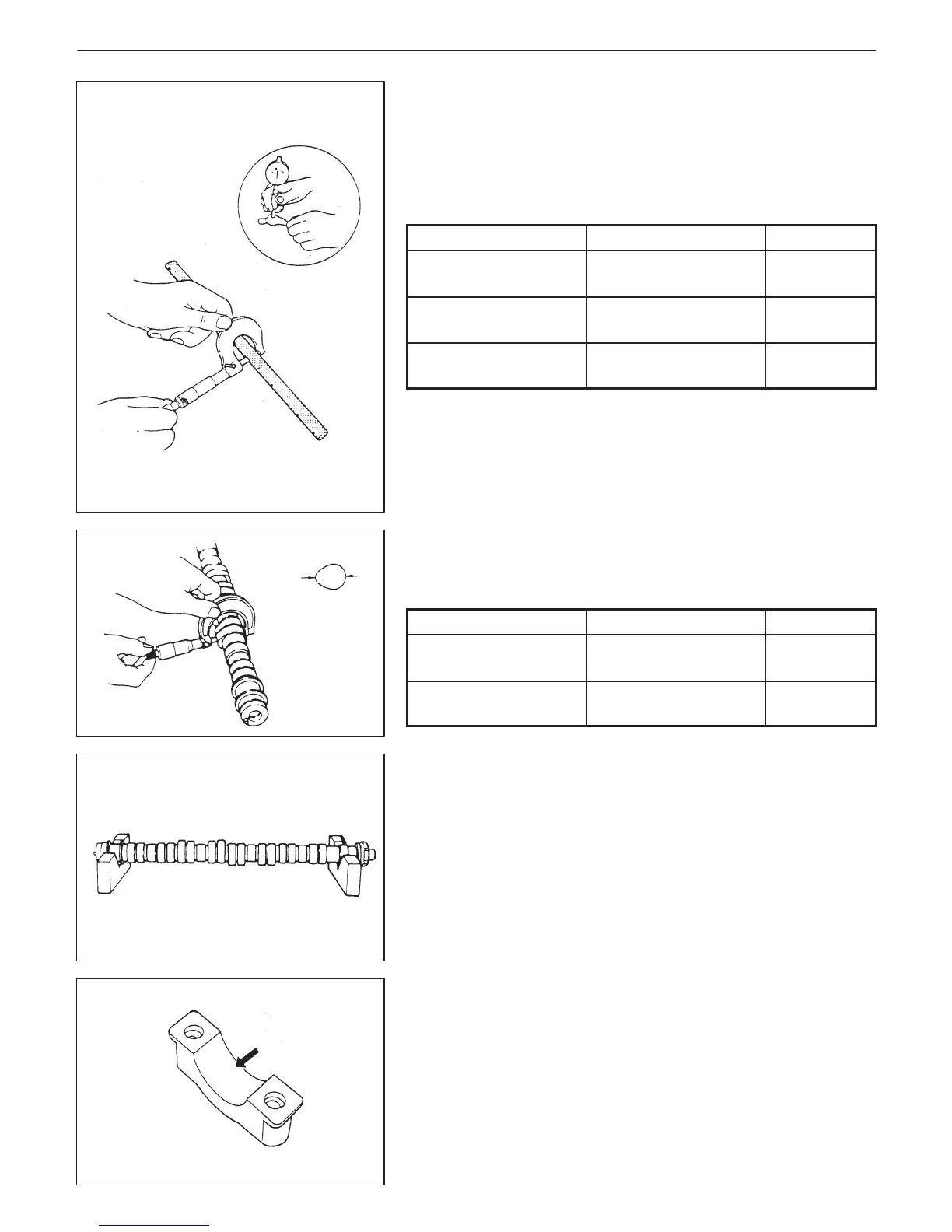

Camshaft Runout

Hold camshaft between two “V” blocks, and measure runout by us-

ing a dial gauge.

If runout exceeds the limit, replace camshaft.

Runout limit: 0.10 mm (0.0039 in.)

Camshaft Journal Wear

Check camshaft journals and camshaft housings for pitting,

scratches, wear or damage.

If any malcondition is found, replace camshaft or cylinder head with

housing. Never replace cylinder head without replacing housing.

Loading...

Loading...