8G-8 IMMOBILIZER CONTROL SYSTEM

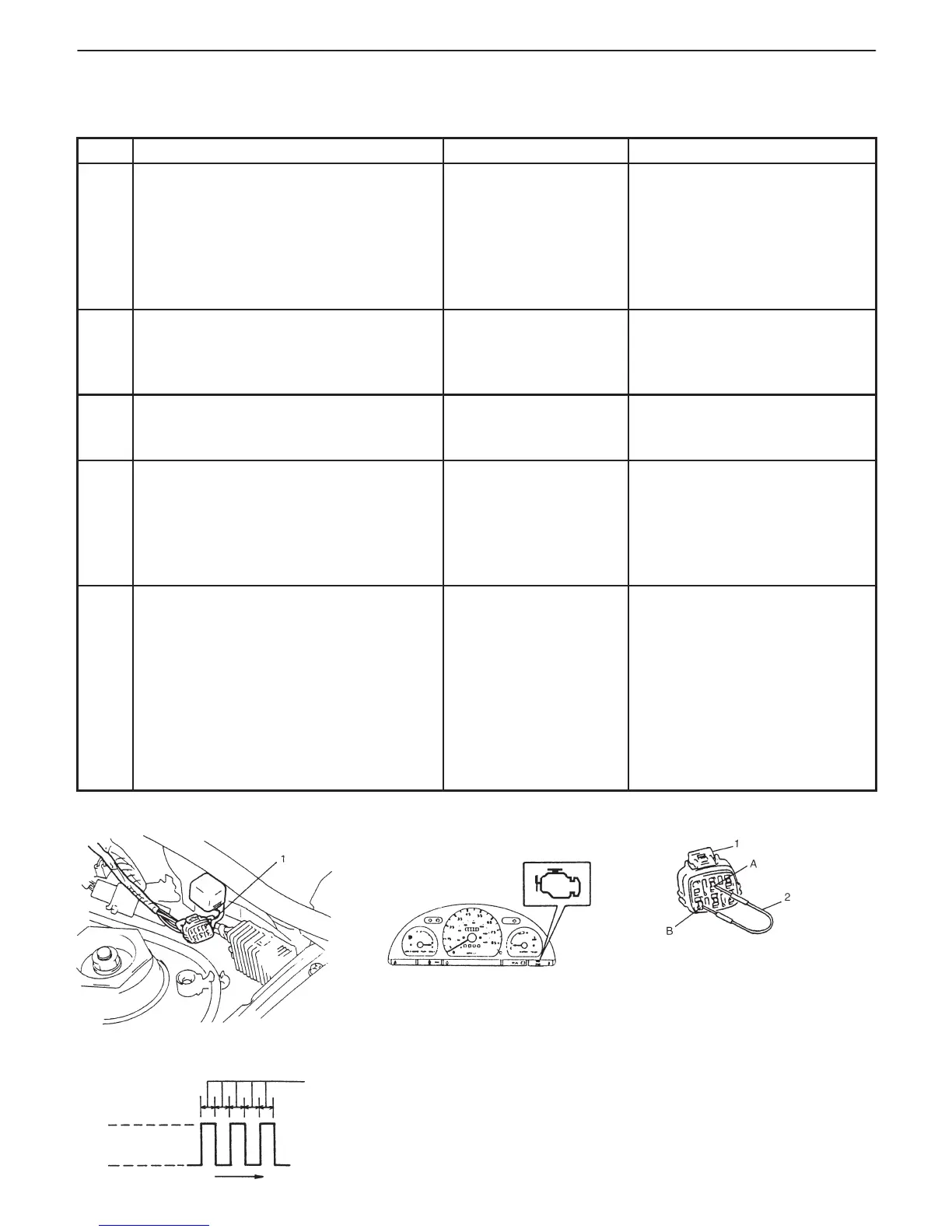

Fig. 1 for Step 1 Fig. 2 for Step 1 Fig. 3 for Step 2

1. Monitor coupler

2. Service wire

A: Diagnosis switch terminal

B: Ground terminal

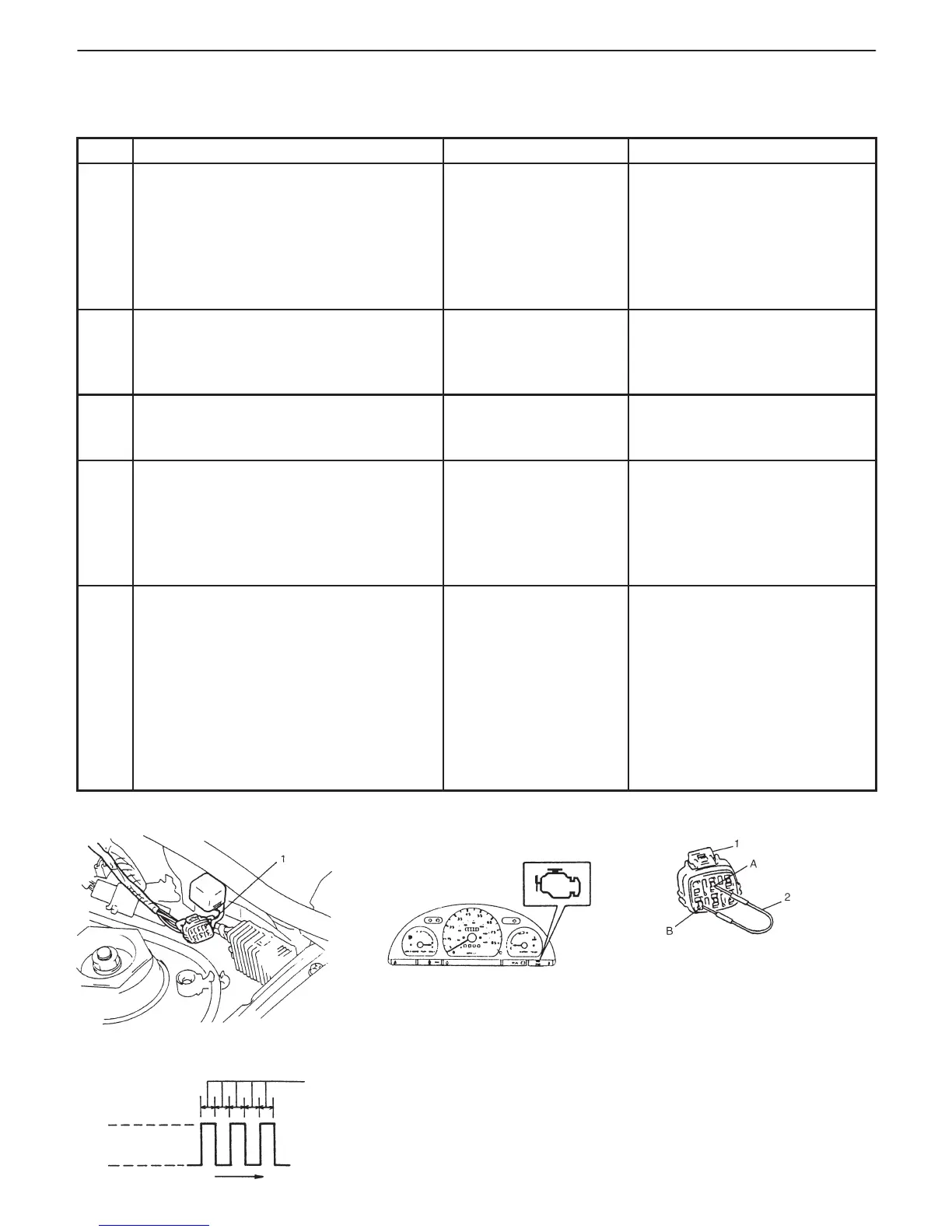

Fig. 4 for Step 3

“CHECK ENGINE” light

0.5

ON

OFF

TIME (sec.)

DIAGNOSTIC FLOW TABLE

<Vehicle equipped with monitor coupler>

STEP ACTION YES NO

1 1) Make sure that diagnosis switch

terminal in monitor coupler is not

grounded by service wire. See Fig. 1.

2) Check malfunction indicator lamp

while ignition switch is ON (but without

starting engine). See Fig. 2.

Dose malfunction indicator lamp flash?

Go to Step 3. D If malfunction indicator lamp

remains ON, go to Step 2.

D If malfunction indicator lamp

remains OFF, go to

“MALFUNCTION INDICATOR

LAMP CHECK” in Section 6.

2 1) Using service wire, ground diagnosis

switch terminal in monitor coupler.

See Fig. 3.

Dose malfunction indicator lamp flash?

Immobilizer control

system is in good

condition.

Go to “MALFUNCTION

INDICATOR LAMP CHECK” in

Section 6.

3 Dose malfunction indicator lamp flash as

Fig. 4?

Go to Step 4. Go to “MALFUNCTION

INDICATOR LAMP CHECK” in

Section 6.

4 1) Check DTC stored in Immobilizer

Control Module referring to

“DIAGNOSTIC TROUBLE CODE

CHECK (IMMOBILIZER CONTROL

MODULE)” in this section.

Is there any DTC(s)?

Go to flow table for

DTC No.

Go to Step 5.

5 1) Check DTC stored in ECM referring to

“DIAGNOSTIC TROUBLE CODE

CHECK (ECM)” in this section.

Is there any DTC(s)?

Go to flow table for

DTC No.

Substitute a known-good ECM

and recheck.

NOTE:

After replacing with a known-

good ECM, register ECM/

Immobilizer Control Module

code in ECM by performing

procedure described in

“Procedure after ECM

Replacement” section.

Loading...

Loading...