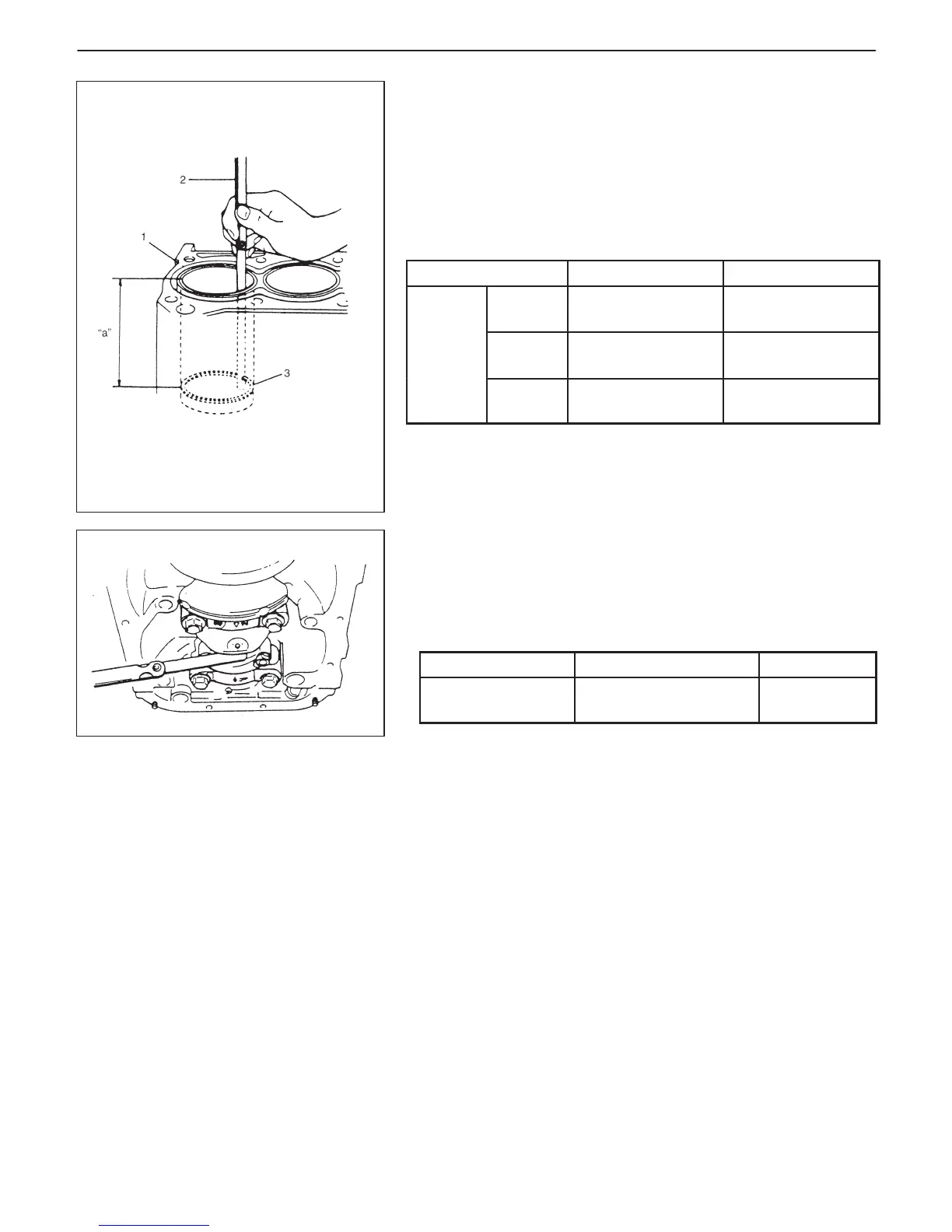

1. Cylinder block

“a”: 120 mm (4.72 in.)

6A1-58 ENGINE MECHANICAL (G13B, 1-CAM 16-VALVES ENGINE)

Piston Rings

To measure end gap, insert piston ring (3) into cylinder bore and

then measure the gap by using thickness gauge (2).

If measured gap is out of specification, replace ring.

NOTE:

Decarbon and clean top of cylinder bore before inserting pis-

ton ring.

Item

Standard Limit

Oil ring

0.2 – 0.7 mm

(0.0079 – 0.0275 in.)

1.7 mm

(0.0669 in.)

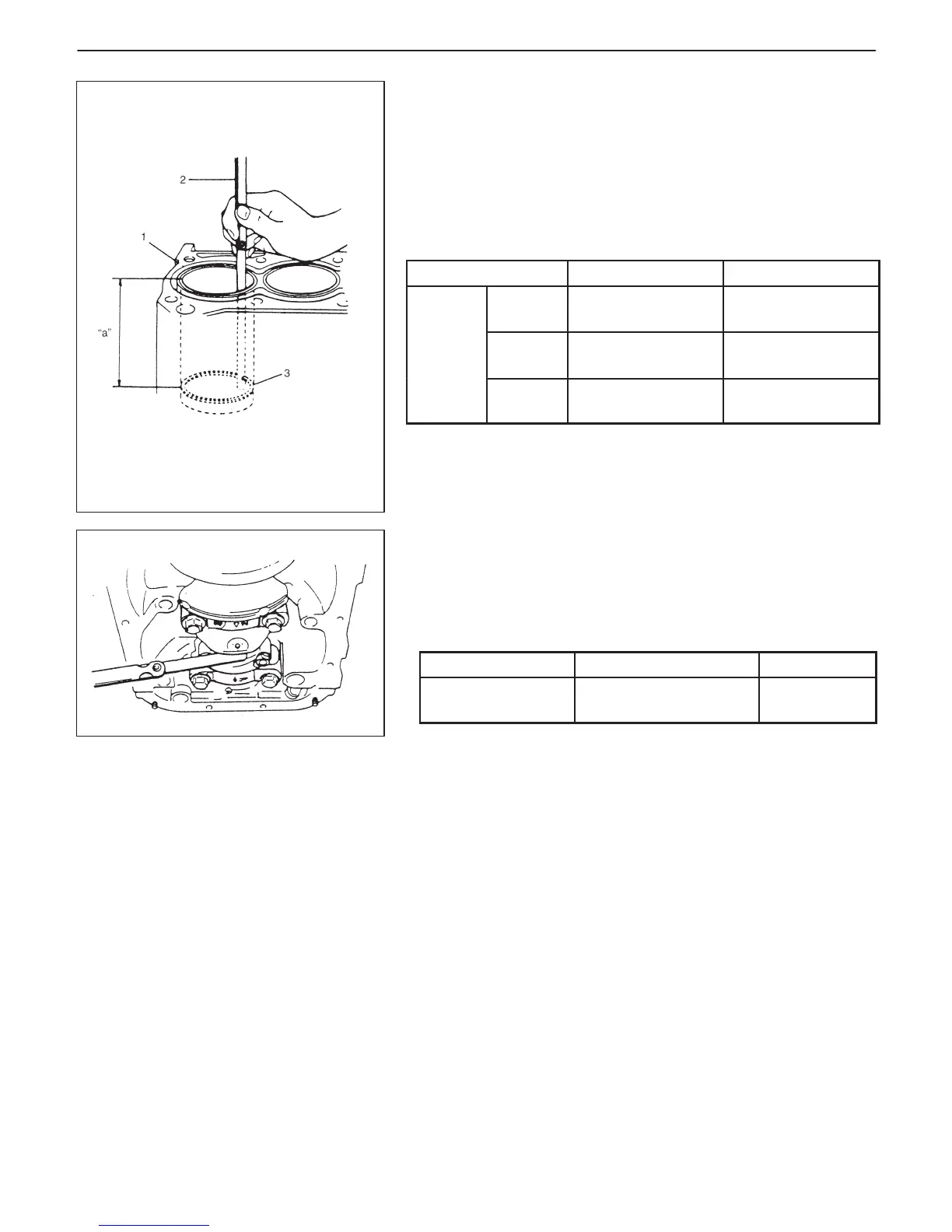

Connecting Rod

D Big-end side clearance:

Check big-end of connecting rod for side clearance, with rod fitted

and connected to its crank pin in the normal manner. If measured

clearance is found to exceed its limit, replace connecting rod.

Item

Standard Limit

Big-end side

clearance

0.10 – 0.20 mm

(0.0039 – 0.0078 in.)

0.35 mm

(0.0137 in.)

D Connecting rod alignment:

Mount connecting rod on aligner to check it for bow and twist and,

if limit is exceeded, replace it.

Limit on bow: 0.05 mm (0.0020 in.)

Limit on twist: 0.10 mm (0.0039 in.)

Loading...

Loading...