3-60 SHB 28Z3 EN – Edition 2.0 * 28z3s314.fm

Maintenance

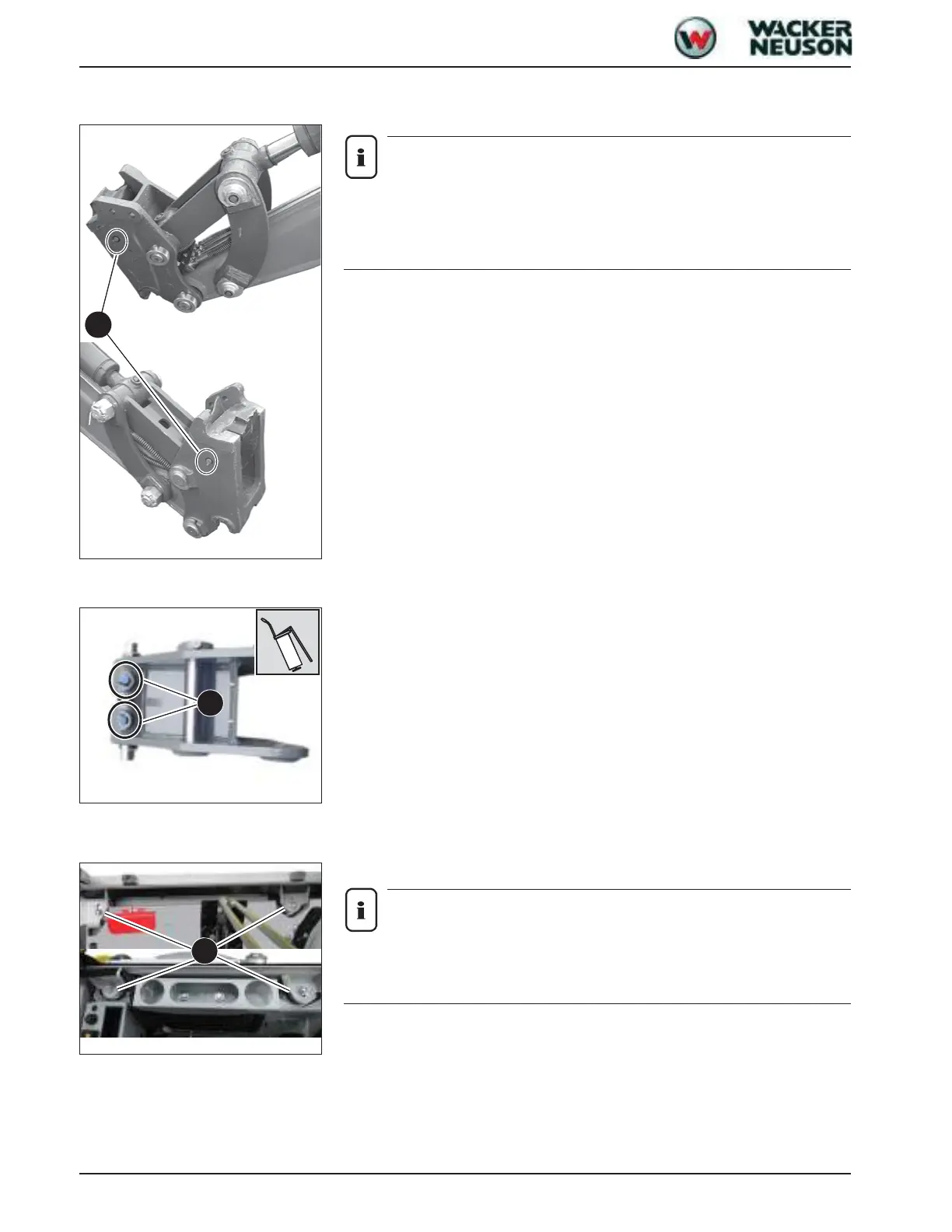

Lubrication points of hydraulic quickhitch (option)

Notice!

Before picking up an attachment, the driver must ensure that it can be hitched cor-

rectly by removing all dirt on either claw of the quickhitch.

Carry out maintenance on the quickhitch once a day with the other maintenance

work for the machine.

Carry out visual checks for possible defects, damage or cracks.

Remove all dirt on and around moving parts.

The claws must be clean and slightly greased.

Apply grease to the friction surfaces of the lock mechanism via 2 grease nipples 16 on

either side of the quickhitch (see Fig. 87).

Before starting work, check the acoustic signal. You must be able to hear the acoustic sig-

nal as you actuate the switch.

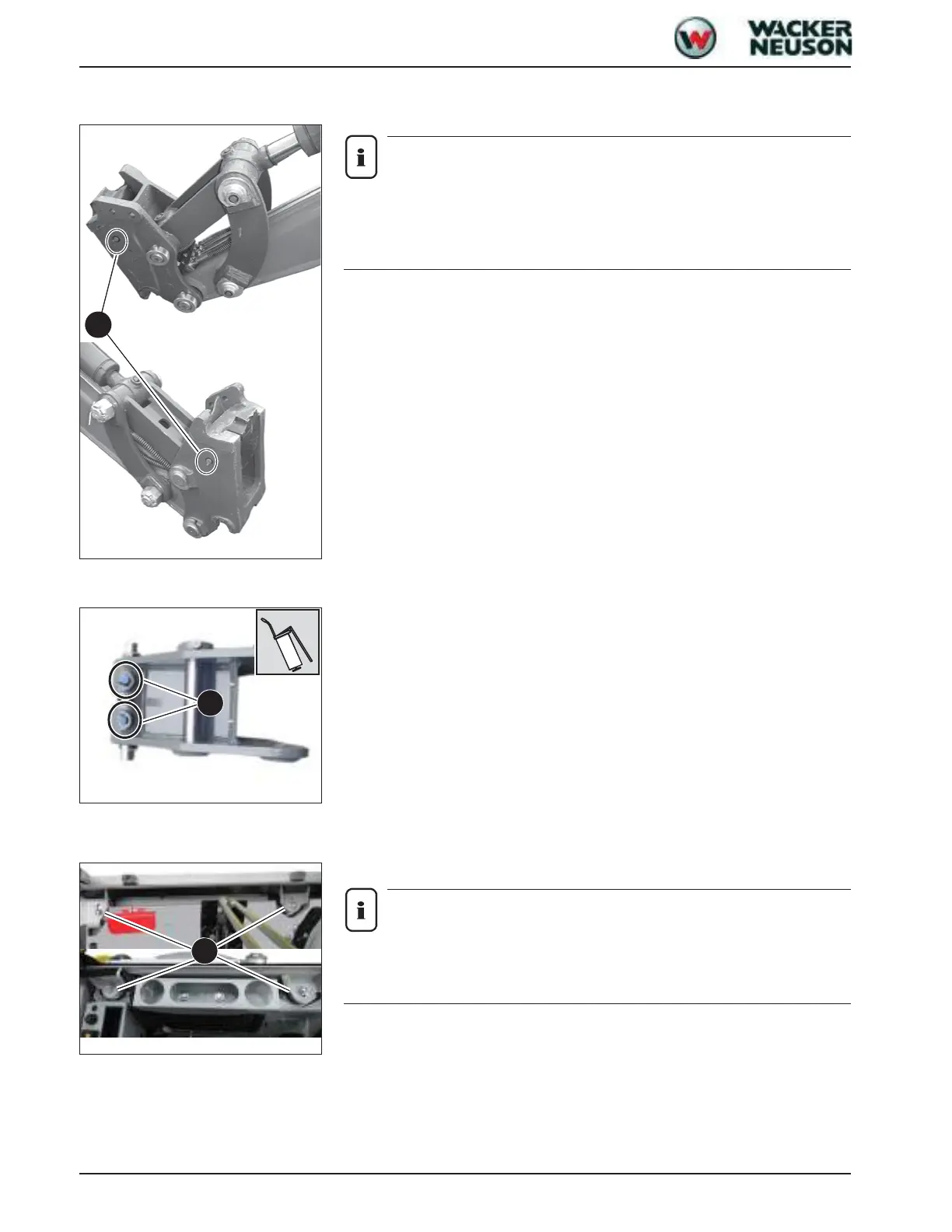

Lubrication points of mechanical quickhitch (option)

☞ Apply grease to lubrication points 17 on the quickhitch (option)

3.22 Cab

☞ Check cab bearings B for damage

Notice!

Check the cab fastening screws for tightness, retighten with a suitable tool if

necessary – see Tightening torques for high-resistance screw connections on

page 2-8

Fig. 87: Quickhitch lubrication points

16

Fig. 88: Quickhitch lubrication points

17

Fig. 89: Cab bearing

B

Loading...

Loading...