4-8 SHB 28Z3 EN – Edition 2.0 * 28z3s410.fm

Engine

Notice!

Apply a thin coat of oil to the threads and contact surfaces before mounting.

Caution!

Bear in the mind the order for tightening the cylinder-head bolts!

4.6 Checking the injection nozzles

Pressure check

☞ Ball-type cock on fuel filter in the “OFF” position

☞ Clean the area around the nozzles

☞ Remove the injection line and the injection nozzle

☞ Connect the injection nozzle with the high pressure line of the nozzle tester

☞ Slowly increase pressure until the nozzle ejects fuel and read the pressure off the pres-

sure gauge

☞ If the injection pressure is too low, replace the spacer in the nozzle by a thicker one. If

the pressure is too high, replace the spacer by a thinner one.

➥ Injection pressure: 118 – 128 bar (1713 – 1858 psi)

• Spacer thickness of 0.1 mm (0.004”) corresponds to modification by 6.9 – 9.8 bar (100

– 142 psi)

• Check the pressure again

• Check the injection nozzle for drips after it has ejected fuel

☞ Create a pressure of about 20 bar (290 psi) below injection pressure and check

whether fuel drips from the nozzle

• Install the nozzle

• Open the ball-type cock on the fuel filter again

Fig. 3: Nozzle tester

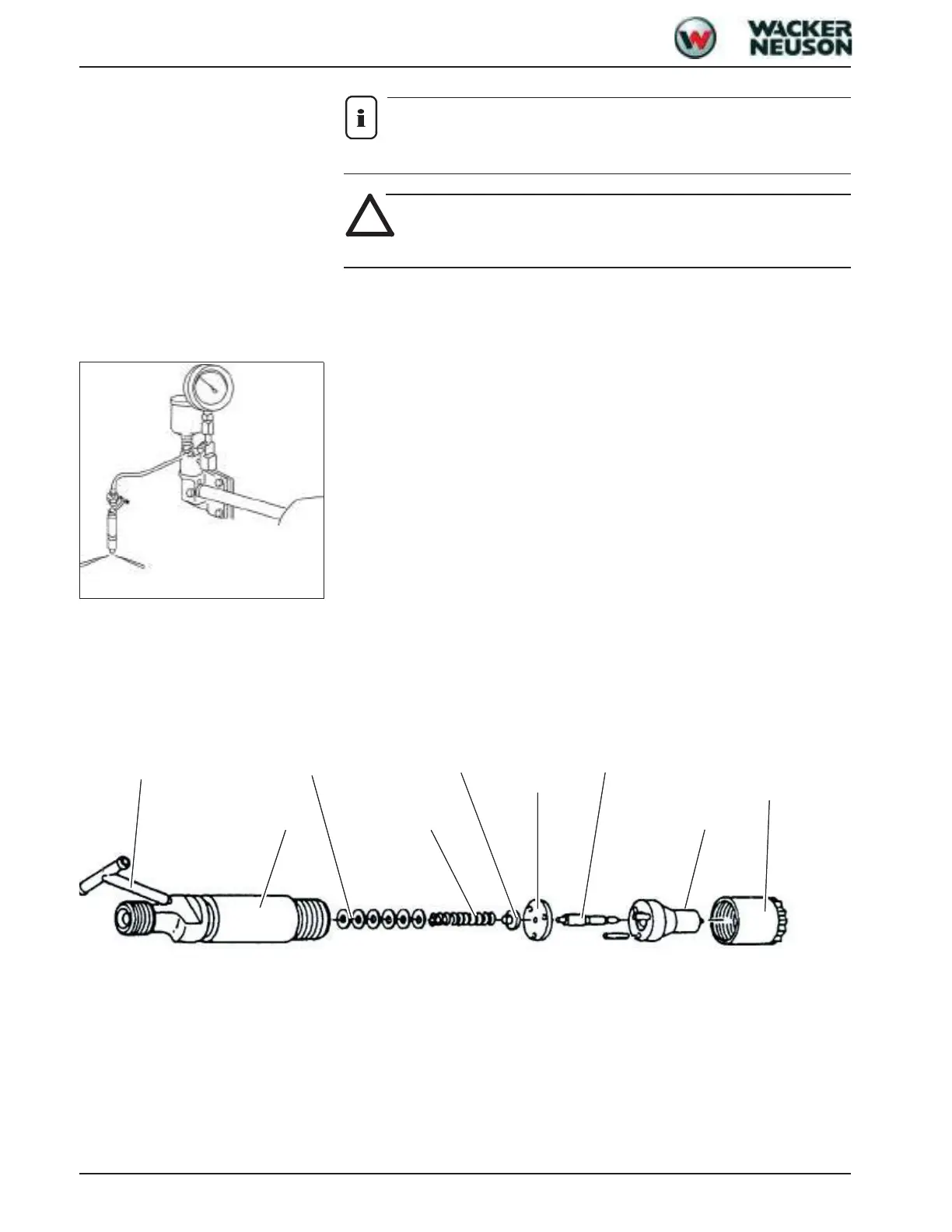

Leak oil line Compression

spring seat

Nozzle needle

Pressure spring centring

Nozzle body

Lower nozzle screw fitting

Compression

spring

Upper nozzle screw fitting

Spacers

Loading...

Loading...