4-16 SHB 28Z3 EN – Edition 2.0 * 28z3s410.fm

Engine

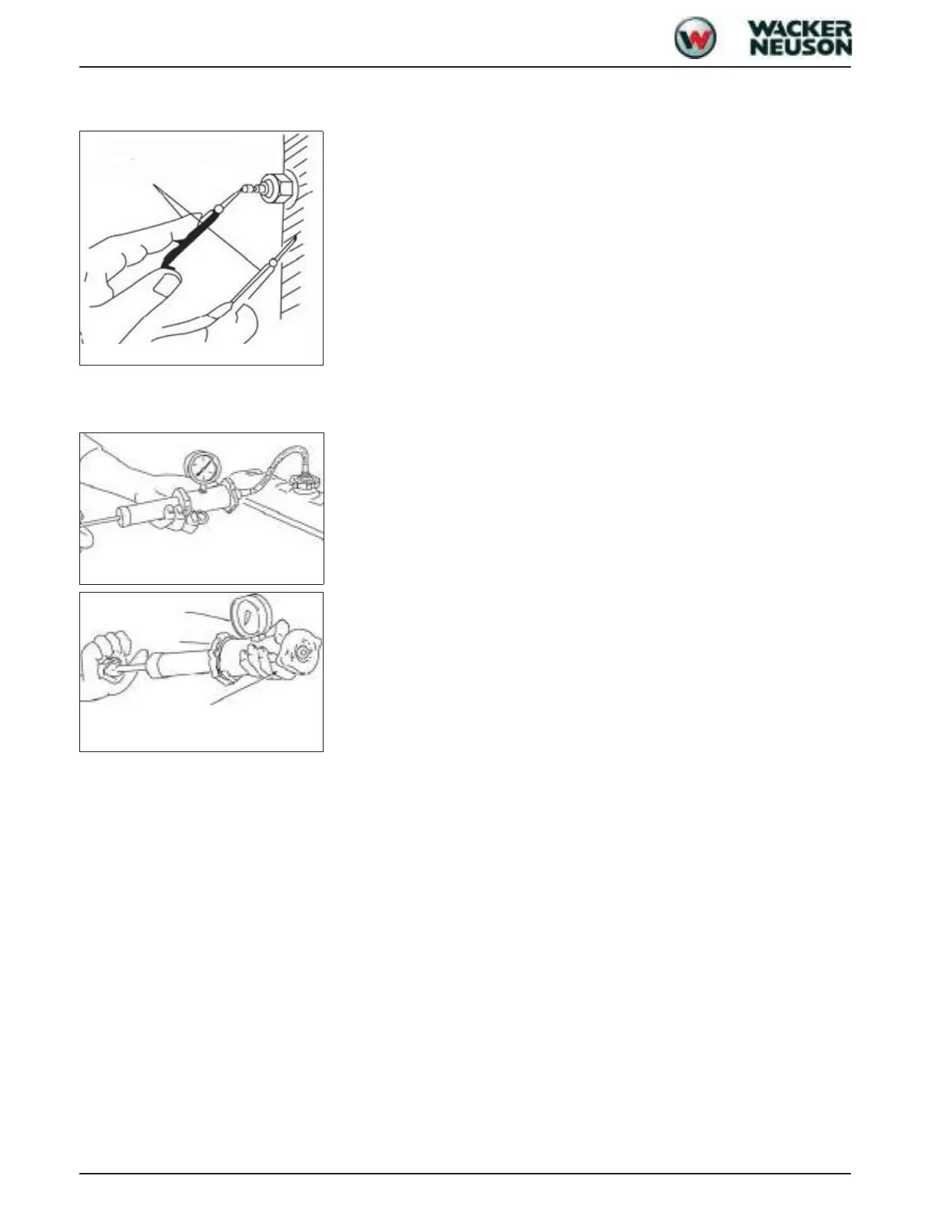

4.14 Oil pressure switch

☞ Remove the cable connection from the oil pressure switch (in the area of the cutoff

solenoid)

☞ Start the engine, check for correct idling speed

☞ Measure the resistance of the oil pressure switch as shown by means of an ohmmeter.

➥ Oil pressure switch OK: infinite resistance

➥ The oil pressure switch is defective if the oil can pass

The oil pressure can also be measured with a mechanical dial gauge

☞ Remove the oil pressure switch and replace with the dial gauge

☞ Start the diesel engine and measure the oil pressure

➥ Replace the oil pressure switch if defective or determine the cause for insufficient oil

pressure

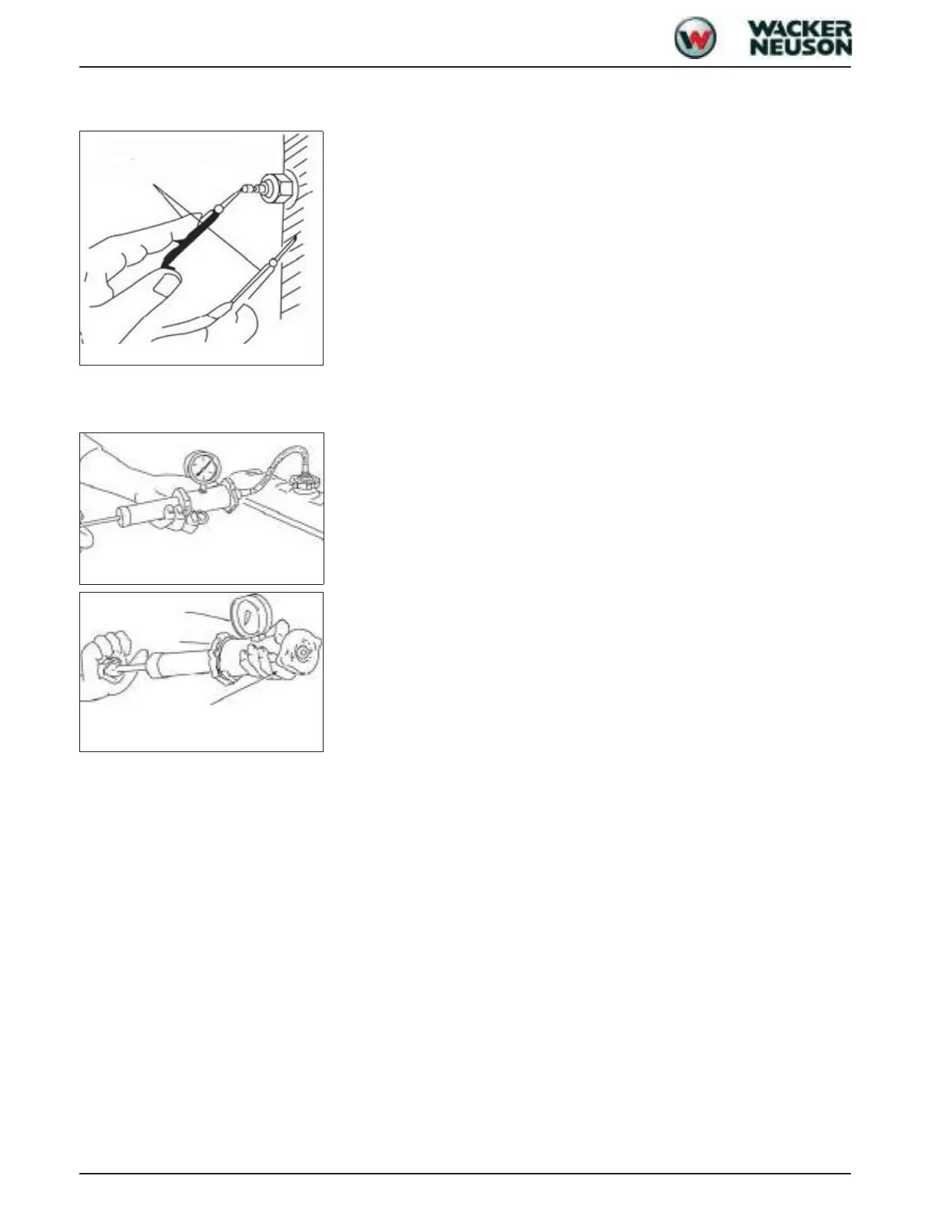

4.15 Checking the coolant circuit

Leakage check

☞ Fill up the radiator completely

☞ Mount an adapter on the radiator as shown

☞ Increase the pressure in the cooling system by means of a hand pump to about 1 bar

(15 psi)

➥ Check the lines and the connections for leaks if the pressure drops at the pressure

gauge

Checking the radiator cap

☞ Remove the radiator cap and mount it onto the adapter as shown

☞ Increase the pressure to about 1 bar (15 psi) (stamped onto the radiator cap) with the

hand pump

➥ The radiator cap must open within this pressure range

4.16 Cleaning the cooling water channels

☞ Drain the coolant – see chapter Draining coolant on page 3-23

☞ Fill the cooling circuit with water

☞ Let the engine run at idling speed for about 5 – 10 minutes

☞ Drain the water from the cooling circuit again

☞ Refill the coolant – see chapter Checking/filling up coolant on page 3-22

4.17 Coolant and fuel hoses

☞ Check the coolant and fuel hoses regularly to ensure that they are not kinked, cracked

or damaged

➥ Renew coolant and fuel hoses every 2 years

Fig. 24: Oil pressure switch

Fig. 25: Checking the radiator for leaks

Fig. 26: Checking the radiator cap

Loading...

Loading...